Speed reducing mechanism of paper splitting machine

A technology of deceleration mechanism and slitting machine, which is applied in the field of papermaking machinery, can solve problems such as poor ink application and poor printing effect, and achieve the effects of preventing light spots and pressure roller marks, good printing effect, and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

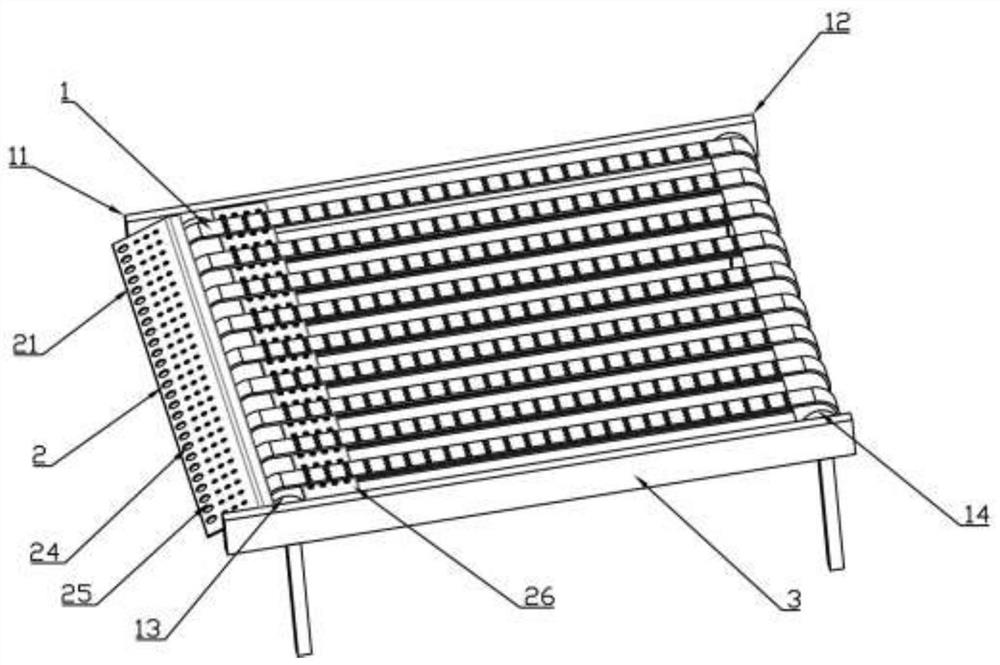

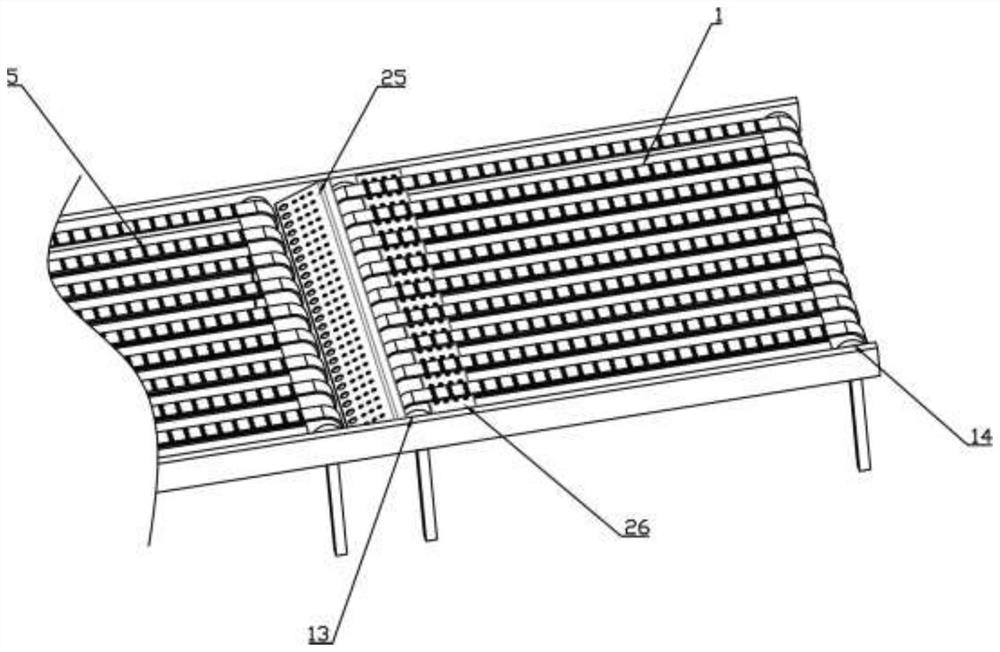

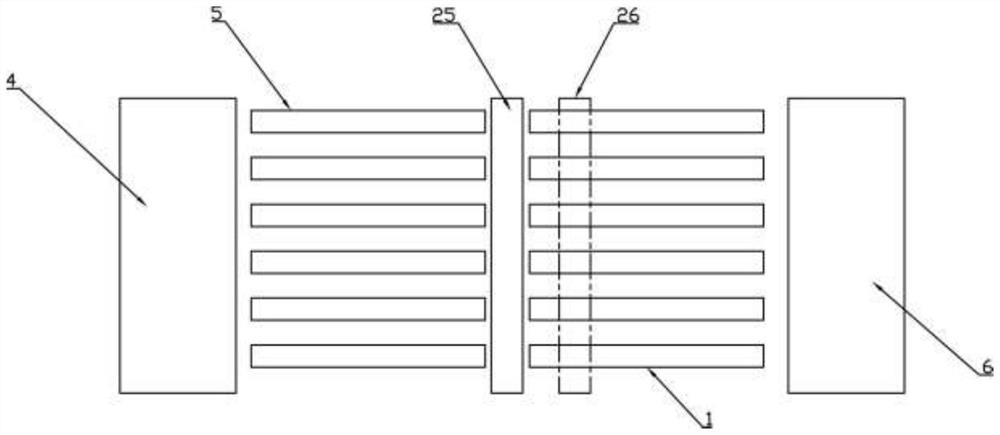

[0031] This embodiment discloses a deceleration mechanism for a paper slitter, including a slow delivery belt 1 , a vacuum suction device 2 and a bracket 3 . The vacuum suction device 2 is arranged below the slow-speed delivery belt 1 and absorbs the paper on the slow-speed delivery belt 1 . The bracket 3 supports the slow conveyor belt 1 and the vacuum suction device 2 .

[0032] The vacuum suction device 2 includes a vacuum plate 21 , a vacuum pump 22 and a conduit 23 connected to the vacuum pump 22 . An air suction hole 24 is provided on the upper surface of the vacuum plate 21 , and a downward suction force is formed at the air suction hole 24 after the vacuum plate 21 is sucked by the conduit 23 .

[0033] There are two vacuum panels 2 , including a first vacuum panel 25 and a second vacuum panel 26 . One end of the slow delivery belt 1 is a paper feed end 11, and one end is a paper discharge end 12. The two ends of the slow delivery belt 1 are provided with a paper fee...

Embodiment 2

[0038] This embodiment discloses a deceleration mechanism for a paper slitting machine.

[0039] Present implementation is provided with upper belt 7 above slow delivery belt 1 . The rotating speed of upper belt 7 is identical with slow delivery belt 1, and the direction of rotation is opposite to slow delivery belt 1. It can prevent the paper from flying up during conveying.

[0040] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0042] This embodiment discloses a deceleration mechanism for a paper slitting machine.

[0043] In this embodiment, the suction hole 24 on the first vacuum plate 25 is larger at a lower position and smaller at a higher position. And the larger suction hole 24 that is positioned at the lower place is equipped with static elimination bar, can reach and make paper drop fast and eliminate the effect that its surface has static electricity.

[0044] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com