Flexible adjusting and positioning device for aviation high-temperature guide pipe and new manufacturing process

A technology for adjusting positioning and catheters, applied in auxiliary devices, measuring devices, manufacturing tools, etc., can solve problems such as deformation and misalignment, low work efficiency, and wide distribution area, and achieve improved manufacturing accuracy, shortened manufacturing cycle, and large adjustment range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

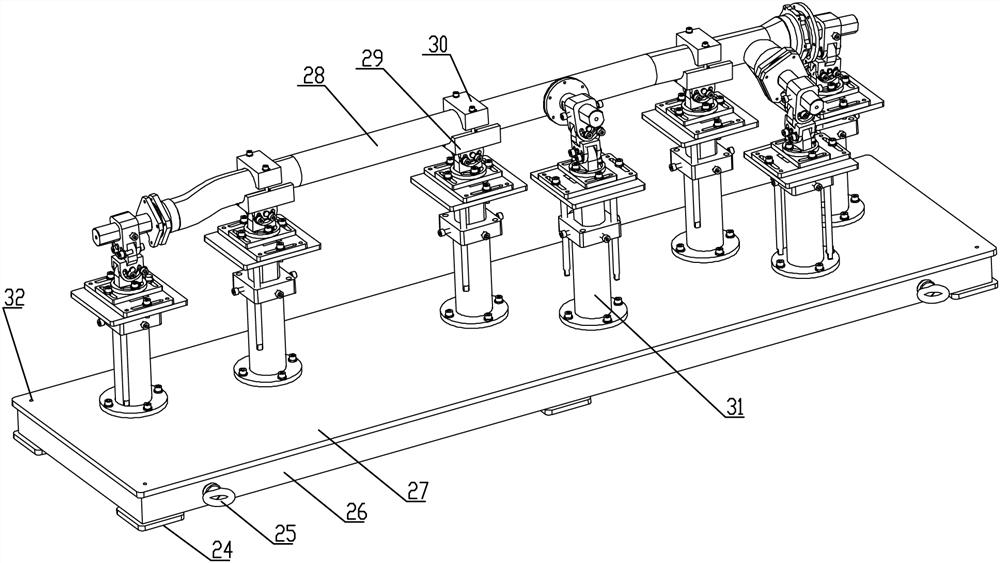

[0068] see Figure 1-4 , in order to solve the problem of precise positioning in the new manufacturing process of aviation high-temperature conduits, a flexible adjustment and positioning device for aviation high-temperature conduits is developed. Multiple sets of three-dimensional adjustment mechanisms are installed on the same plate for combination and matching. Through purely mechanical manual adjustment mechanisms, It can realize the rapid adjustment and precise positioning of the direction, interface, installation hole or installation surface of the aviation high-temperature conduit. The new conduit can realize precise positioning assembly and assembly welding on this flexible adjustment and positioning device, and can ensure that the conduit interface meets the installation requirements on the aircraft. , The direction of the pipeline is consistent with the old one and does not interfere with other components on the machine. It is easy to operate and easy to use.

[0069...

Embodiment 2

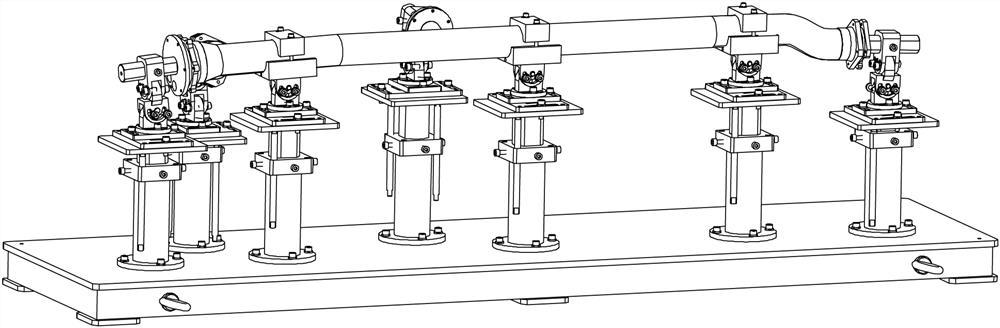

[0080] The typical shape and structure of the aircraft engine high-temperature air duct described in this new manufacturing method is shown in Figure 5-6 :

[0081] 1. For the special-shaped pipe, it is divided into upper and lower half-pipes, which are molded by forming mold tires respectively, and then welded from the middle, with two welds in the middle;

[0082] 2. For standard straight-through pipes, seamless stainless steel pipes are directly cut and blanked;

[0083] 3. Trumpet pipe joints, flanges and conduit connection plates are all CNC machined parts.

[0084] 4. The special-shaped pipe half-pipe mold tire described in the method is a conventional convex-concave die structure designed and manufactured according to the profile digital model of each half-pipe, and is used for compression molding of each half-pipe.

[0085] see Figure 1-2 A method for newly manufacturing aviation high-temperature conduits by using the flexible adjustment and positioning device for...

Embodiment 3

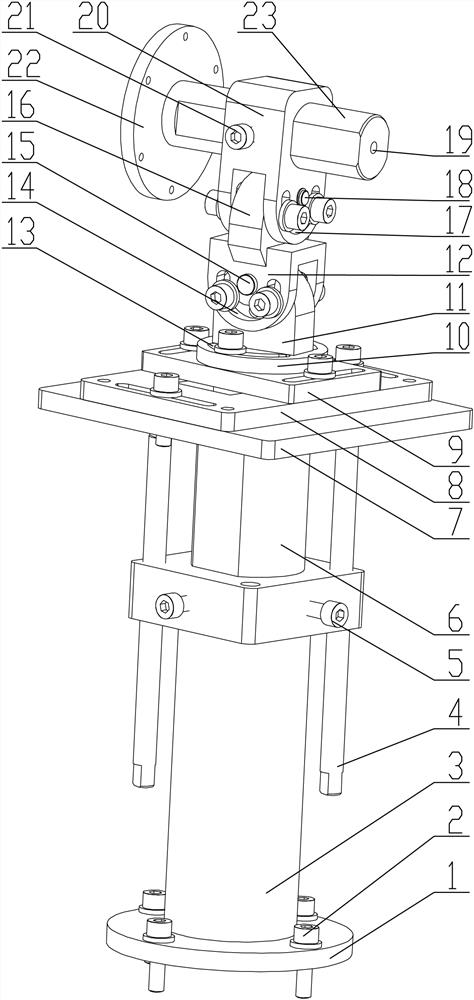

[0118] The working process and principle of the flexible adjustment and positioning device for aviation high-temperature conduits of the present invention:

[0119] 1. The mounting plate, support cylinder and lifting guide sleeve are welded together.

[0120] 2. The mounting plate is used to fix the adjustment device as a whole on the plate.

[0121] 3. The lifting column and the bottom plate are welded together, the lifting column can be lifted up and down in the lifting sliding sleeve, the lifting height can be adjusted by adjusting the screw, and the first locking screw 5 can be positioned and locked.

[0122] 4. The adjusting screw is a fully threaded screw, which is installed in the screw hole of the lifting guide sleeve, and the two ends are processed with flats, which is convenient to use a wrench for adjustment.

[0123] 5. The horizontal adjustment plate can move horizontally on the bottom plate.

[0124] 6. The longitudinal adjustment plate can move longitudinally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com