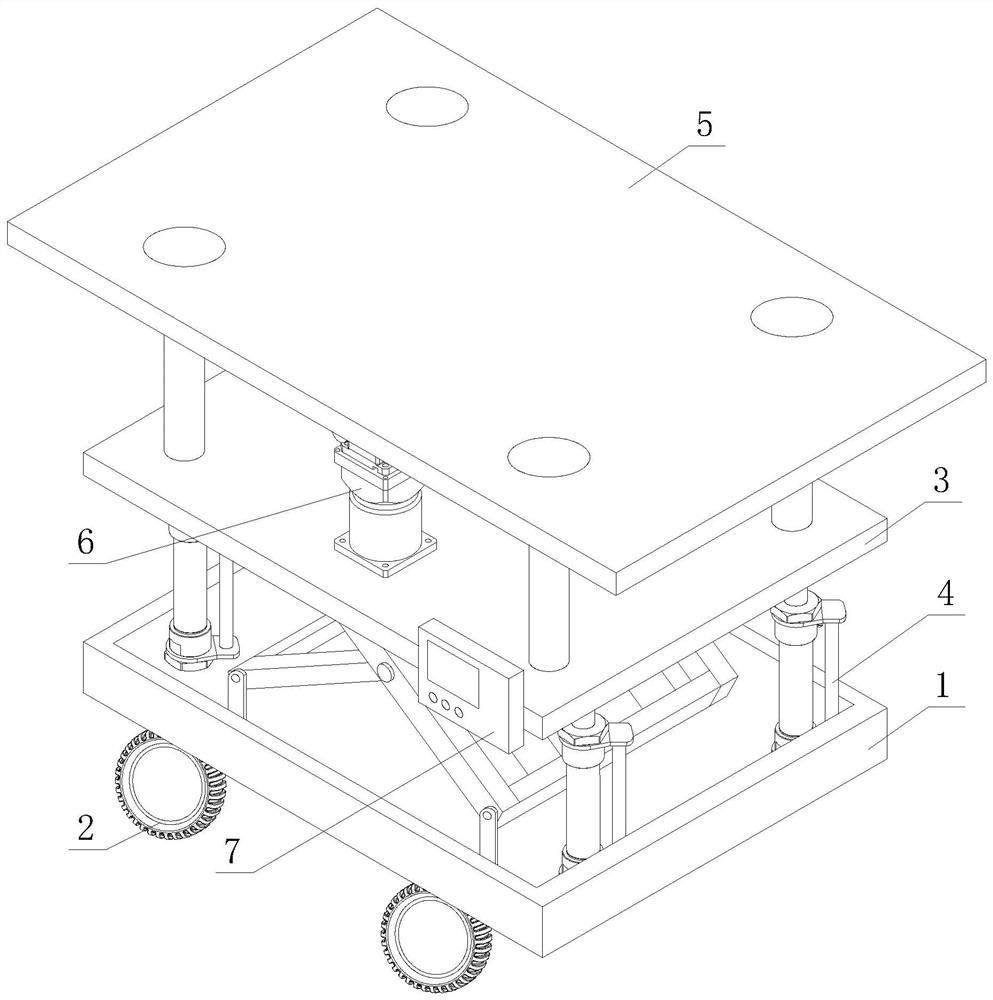

Adjustable jack raising form for building and implementation method of adjustable jack raising form

An adjustable, architectural technology, applied in the direction of construction, building structure, building material processing, etc., can solve the problems of unstable structure, slow lifting, etc., achieve the effect of practical function, good effect, and increase the overall practical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] In order to better demonstrate the implementation process of adjustable jacking formwork for construction, this embodiment proposes an implementation method for adjustable jacking formwork for construction, including the following steps:

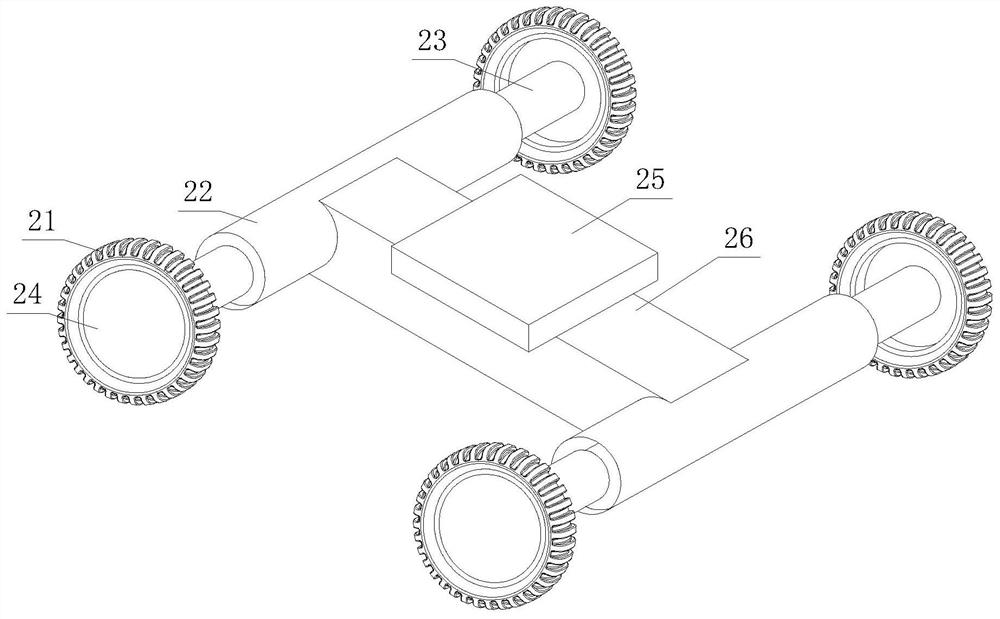

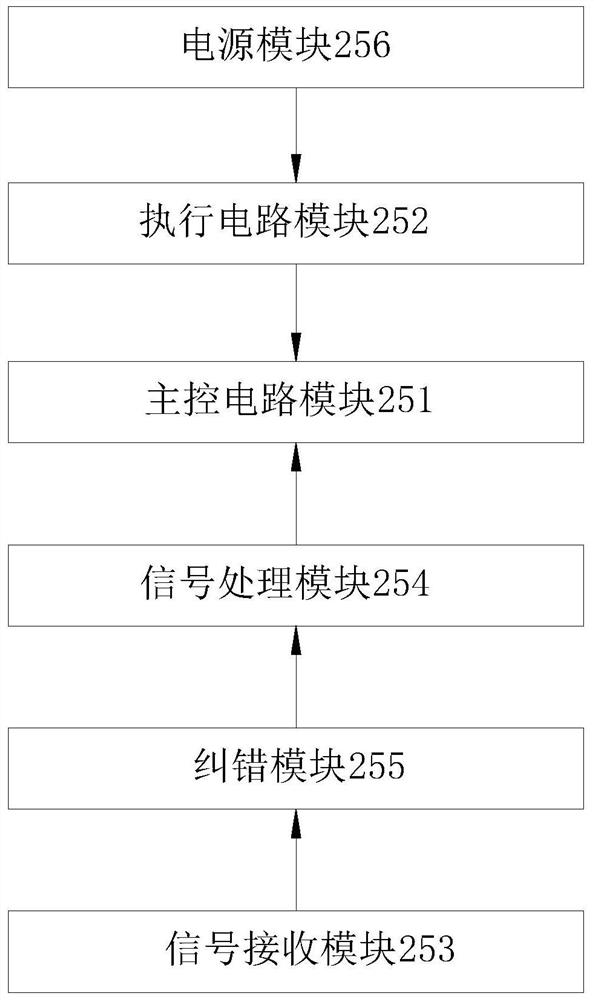

[0046] Step 1: Receive control instructions through the signal receiving module 253 through the signal processing module 254, the signal receiving module 253 transmits the signal to the main control circuit module 251, the main control circuit module 251 controls the execution circuit module 252 to execute, and the execution circuit module 252 transmits information to Move the two-way motor 22 controller to control the motor to drive the roller 24 to move, so as to reach the designated position;

[0047] Step 2: The hydraulic cylinder rod 36 drives the oblique bracket A33 and the oblique bracket B34 to stretch, and drives the load-bearing plate 32 to move upward during the stretching process, thereby driving the jacking template 5 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com