Main bridge deck shot blasting and composite modified asphalt waterproof bonding layer construction process

A technology of composite modified asphalt and waterproof adhesive layer, which is applied in the direction of bridges, bridge parts, bridge construction, etc. It can solve the problems of unguaranteed construction quality and uneven asphalt spreading, so as to avoid overlapping or omission, The construction quality is good, and the effect of ensuring the straightness of the edge line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the technical solutions in the embodiments of the present invention will be described in the following examples, and the described embodiments are merely, and embodiments are intended to be, in rather than all embodiments. Embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in all other embodiments obtained without making creative labor.

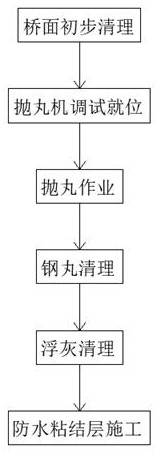

[0036] See figure 1 The present invention provides a technical solution: a construction process of main bridge schist and composite modified asphalt waterproof bonding layer, the main bridge bridge stripper and composite modified asphalt waterproof bonding layer construction process includes the following step:

[0037] Step 1: The bridge surface is initially cleaned;

[0038] Step 2: Shooting machine debugging;

[0039] Step three: shot a hobbing operation;

[0040] Step 4: Pills cleanup;

[0041] Step 5: Sour and clean;

[0042] Step 6: Waterproof bonding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com