A recyclable double-wire twisting device

A cyclic, steel wire technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of poor wire tightening effect, easy wire breakage, multiple positioning parts, etc., to improve processing efficiency and safety performance. , The effect of easy disassembly and assembly, low material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

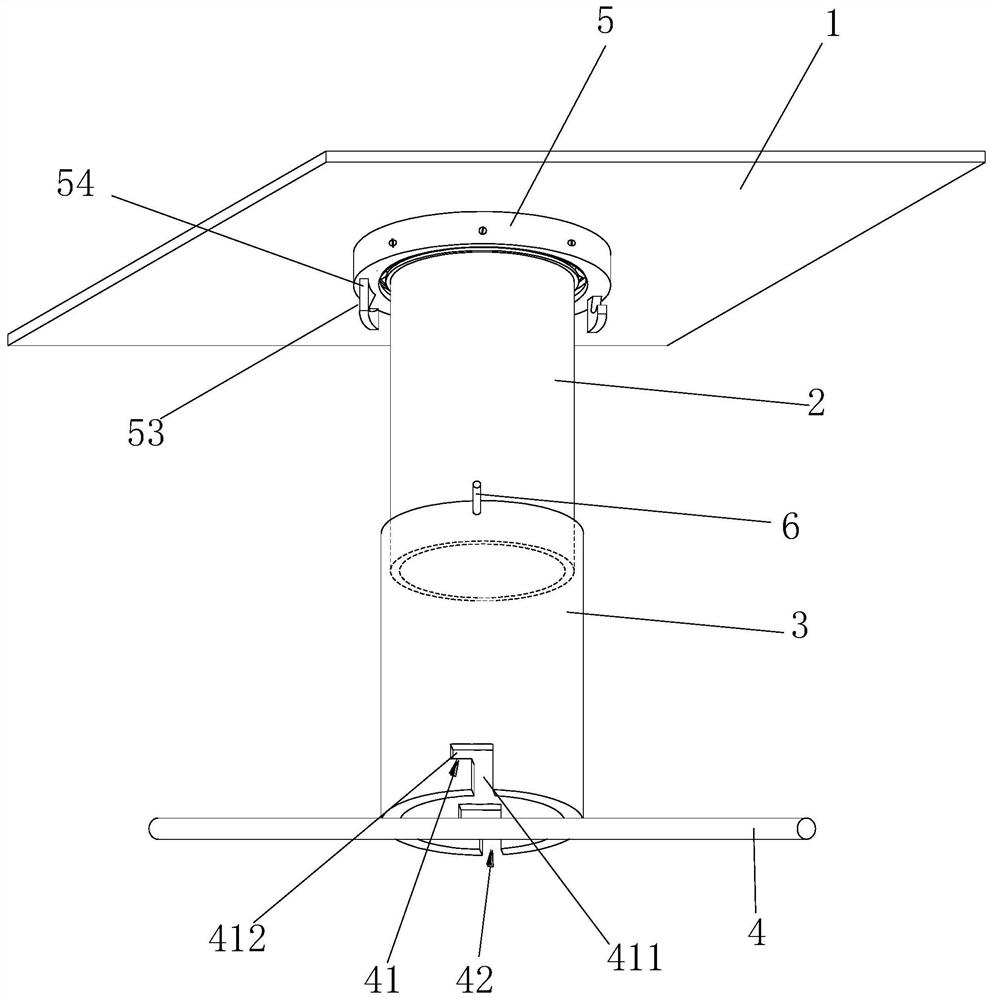

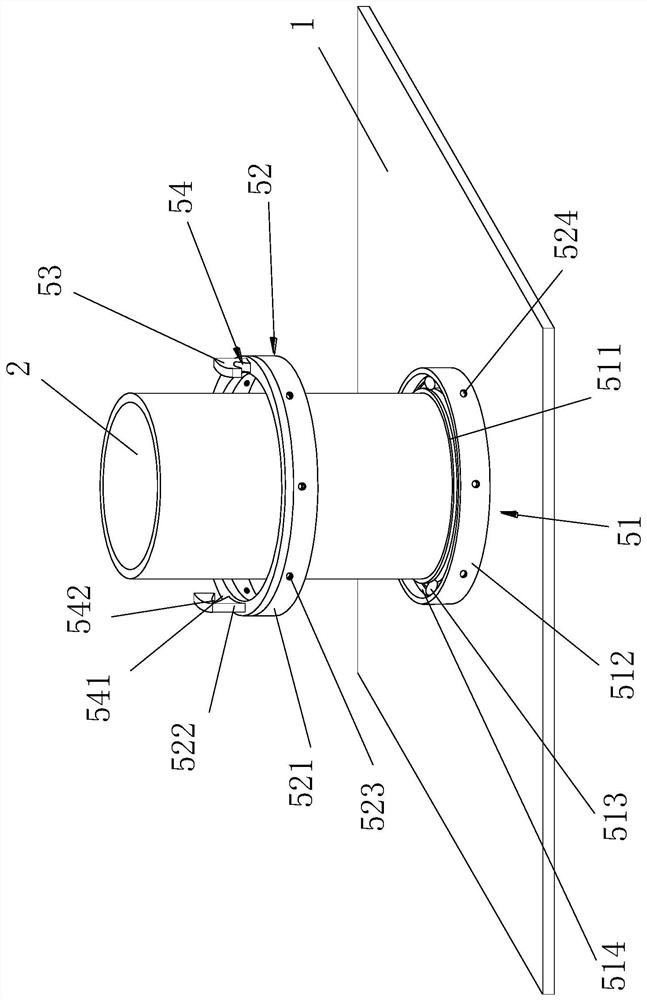

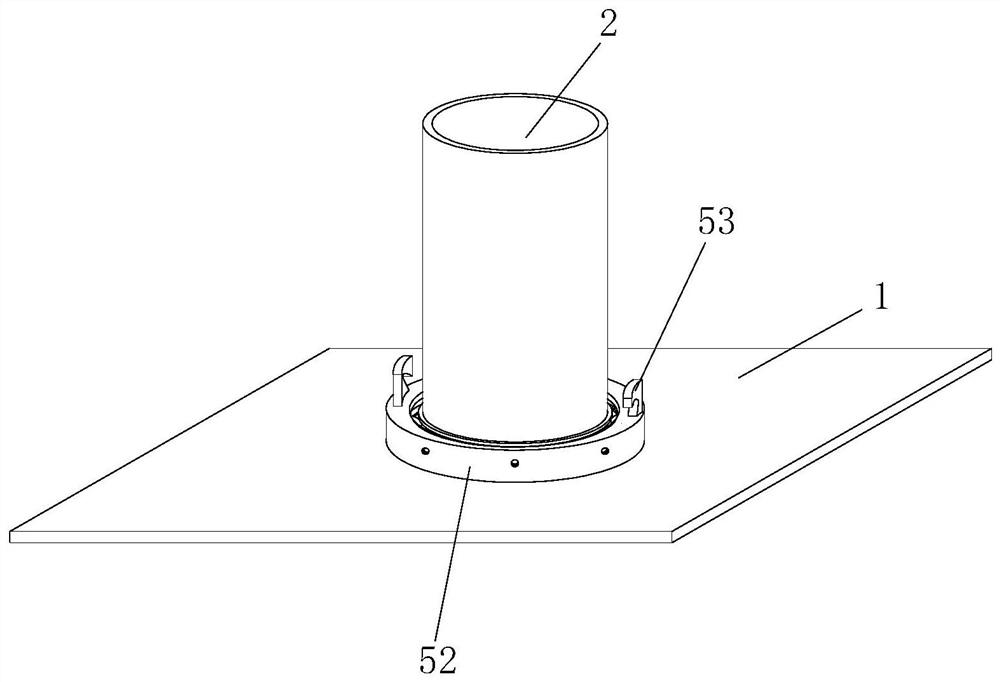

[0030] combine Figure 1 to Figure 4 , a recyclable double-wire screwing device, including a base mechanism and a rotating mechanism, the base mechanism includes a pressure-bearing bracket 1 and a positioning inner cylinder 2, and a first through hole 11 is opened in the middle of the pressure-bearing bracket 1, and the positioning inner The cylinder 2 is fixedly connected to the lower end surface of the pressure bearing bracket 1 outside the first through hole 11 .

[0031] The rotating mechanism includes a rotating outer cylinder 3 and a rotating handle 4, the rotating handle 4 is horizontally connected to the lower end of the rotating outer cylinder 3, and the outer ends of the rotating outer cylinder on both sides of the rotating handle 4 are respectively provided with a first wire hanging buckle notch 41 and The second wire hanging buckle slot 42 .

[0032] The connecting end of the positioning inner cylinder 2 and the pressure-bearing bracket 1 is provided with a rotati...

Embodiment 2

[0045] The above-mentioned recyclable double-wire screwing device is used for the processing work before the pouring of the concrete floor slab. After the plastic light-weight mandrel box used in processing is assembled as a whole, determine the position of the bottom mold hole, drill through holes in pairs, and the two ends of the U-shaped anti-floating wire of the support pass through a pair of through holes respectively.

[0046] Using a recyclable double-wire screwing device, first put the rotating mechanism on the base mechanism, and then place the assembled screwing device on the lower end or side end of the bottom form of the concrete structure. At this time, the screwing device is set on the U-shaped wire drawing. superior. The ends of the U-shaped drawing wire are passed through the positioning inner cylinder and the rotating outer cylinder, and then the two ends of the U-shaped drawing wire are respectively fastened on the first wire hanging buckle notch and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com