Coal-water slurry gasification and coal-fired boiler ultra-low NOx emission integrated collaborative control method

A coal-fired boiler and collaborative control technology, which is applied in the directions of adaptive control, production of combustible gas, general control system, etc., can solve problems such as linkage of ultra-low emission control of coal-fired boilers and the formation of integrated collaborative control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

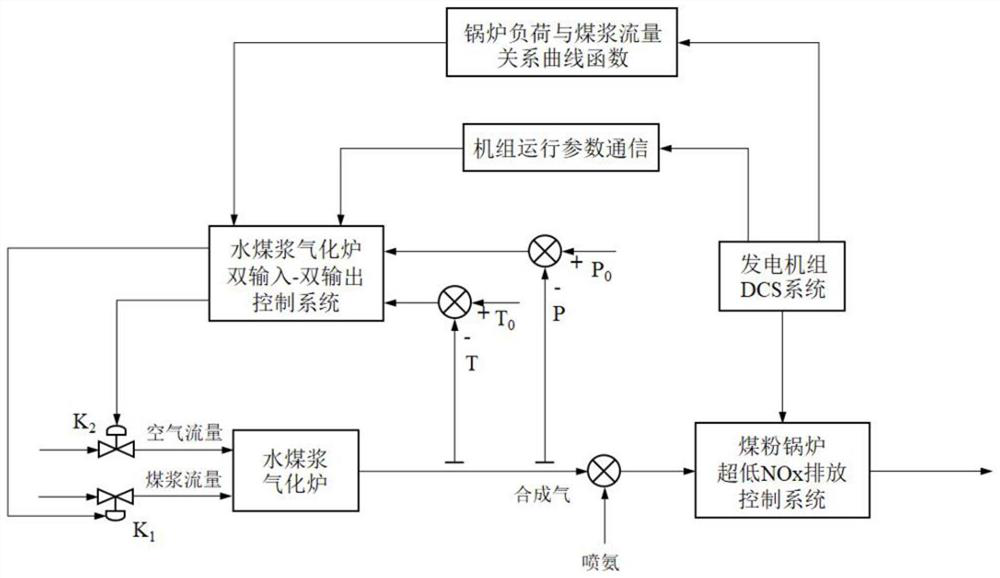

[0022] Such as figure 1 As shown, this embodiment relates to an integrated collaborative control method that matches coal-water slurry pyrolysis gasification control with coal-fired boiler ultra-low NOx emission control, including:

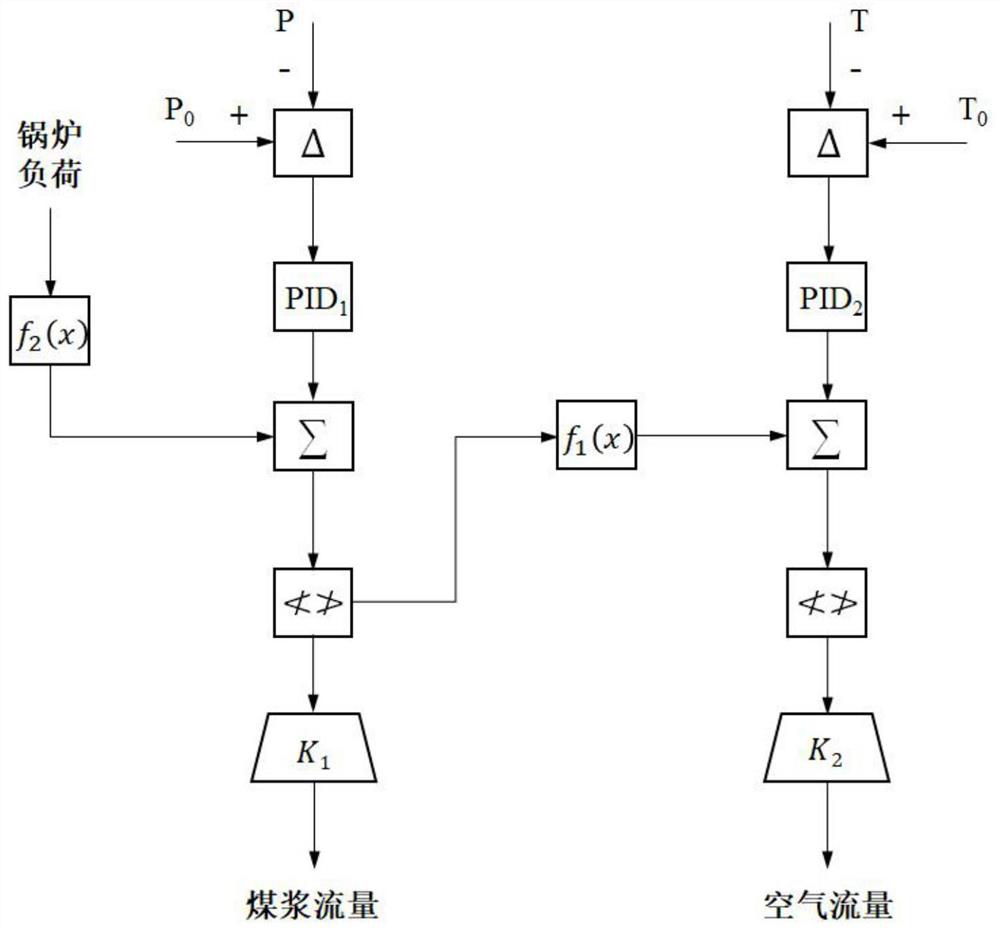

[0023] Step 1) Compare the measured pressure P and temperature T of the pyrolysis synthesis gas at the outlet of the coal-water slurry gasifier with the given pressure value P 0 and temperature setpoint T 0 For comparison, the pressure difference and temperature difference are used as controlled input signals to input the dual-input-double-output control system of the coal-water slurry gasifier, and the output signals are respectively used to control the coal slurry flow of the coal-water slurry gasifier and input to the control valve K 1 and air flow input control valve K 2 .

[0024] The dual-input-double-output control system of the coal-water slurry gasifier includes: based on the dynamic model of the dual-input-double-output system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com