Wafer cleaning method and device for realizing same

A wafer and cleaning liquid technology, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as gate oxide life degradation, smearing effect, device failure, etc., to achieve a solution The effect of rapidly degrading gate oxide life and avoiding wafer charging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

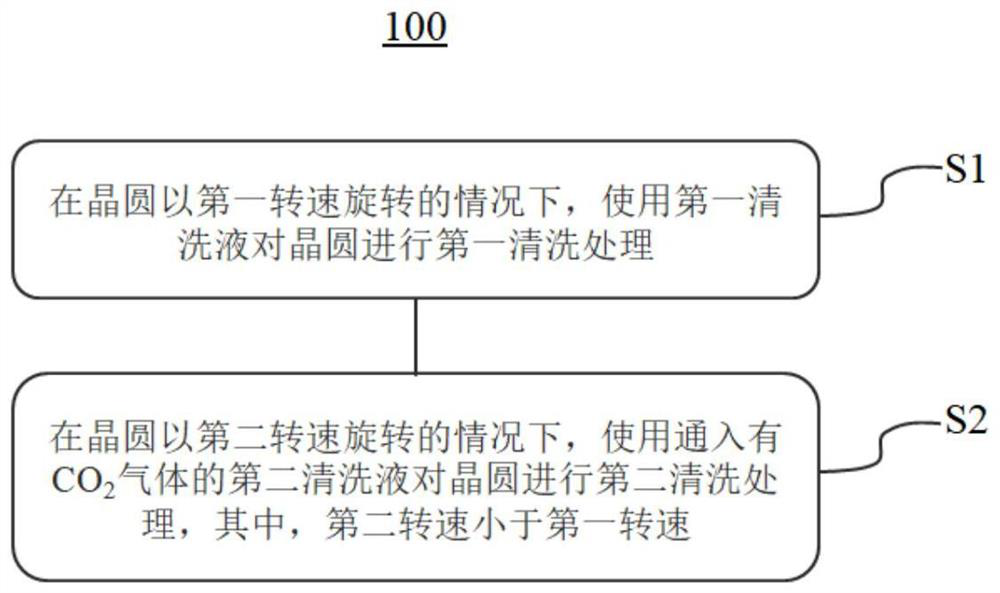

Method used

Image

Examples

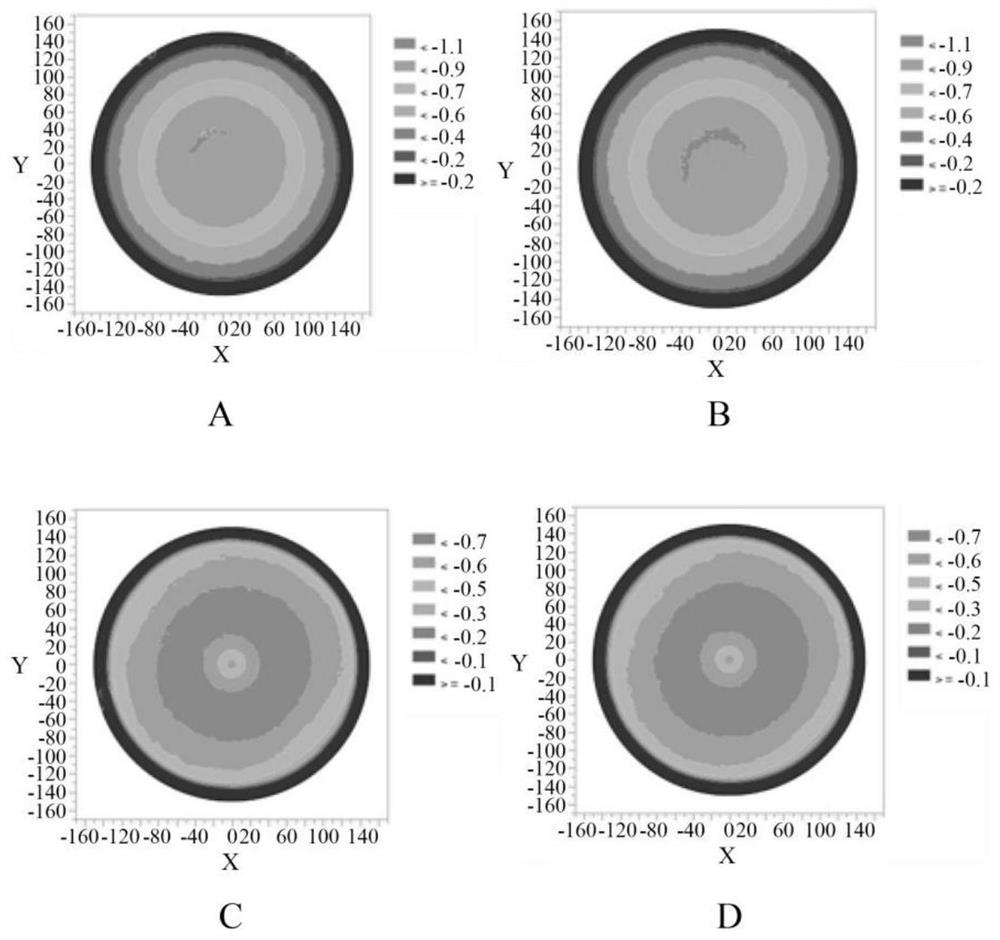

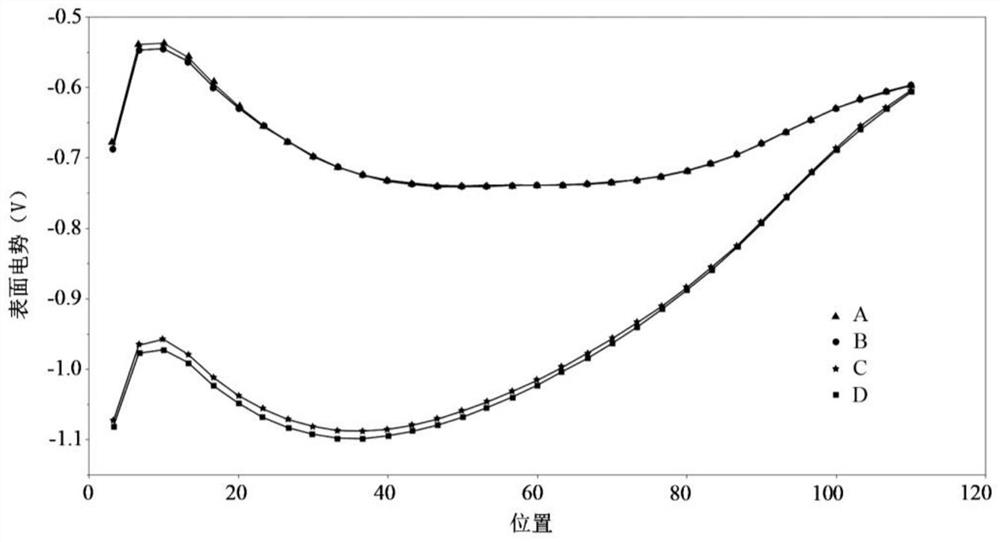

Embodiment Construction

[0014] The present application will be described in detail below in conjunction with the accompanying drawings, and the exemplary implementations mentioned herein are only used to explain the present application, and are not intended to limit the scope of the present application.

[0015] It should be understood that expressions such as "comprises", "comprises", "has", "comprises" and / or "comprising" in this specification are open rather than closed expressions, which mean that the stated features are present. , but does not exclude the existence of one or more other features and / or their combinations. Furthermore, when expressions such as "any of" appear after a list of listed features, they modify the entire list of features, not just the individual features in the list. The expression "and / or" includes any and all combinations of one or more of the associated listed items. In addition, when describing the embodiments of the present application, the use of "may" means "one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com