Heat dissipation device of electronic and electrical equipment

A heat dissipation device, electronic and electrical technology, which is applied to the structural parts of electrical equipment, electrical components, and decoration through conduction heat transfer, etc. Non-uniform material dispersion, uniform heat dissipation effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

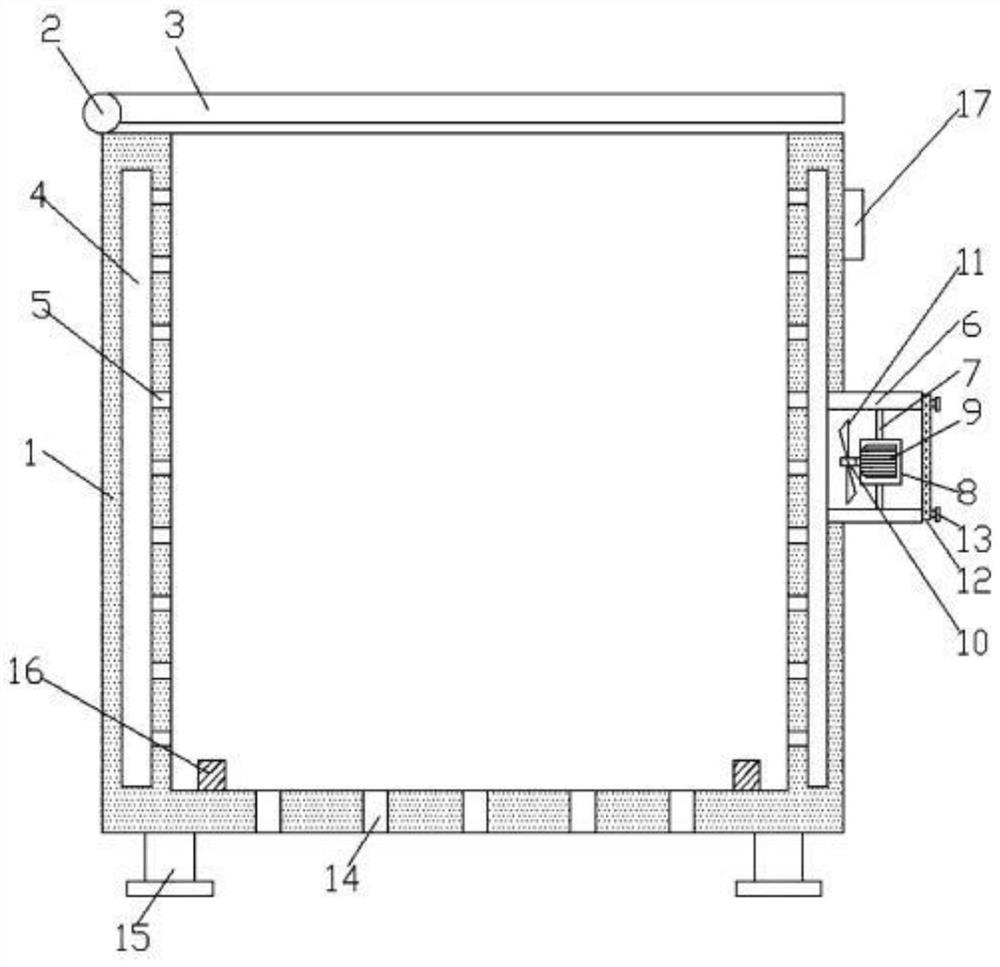

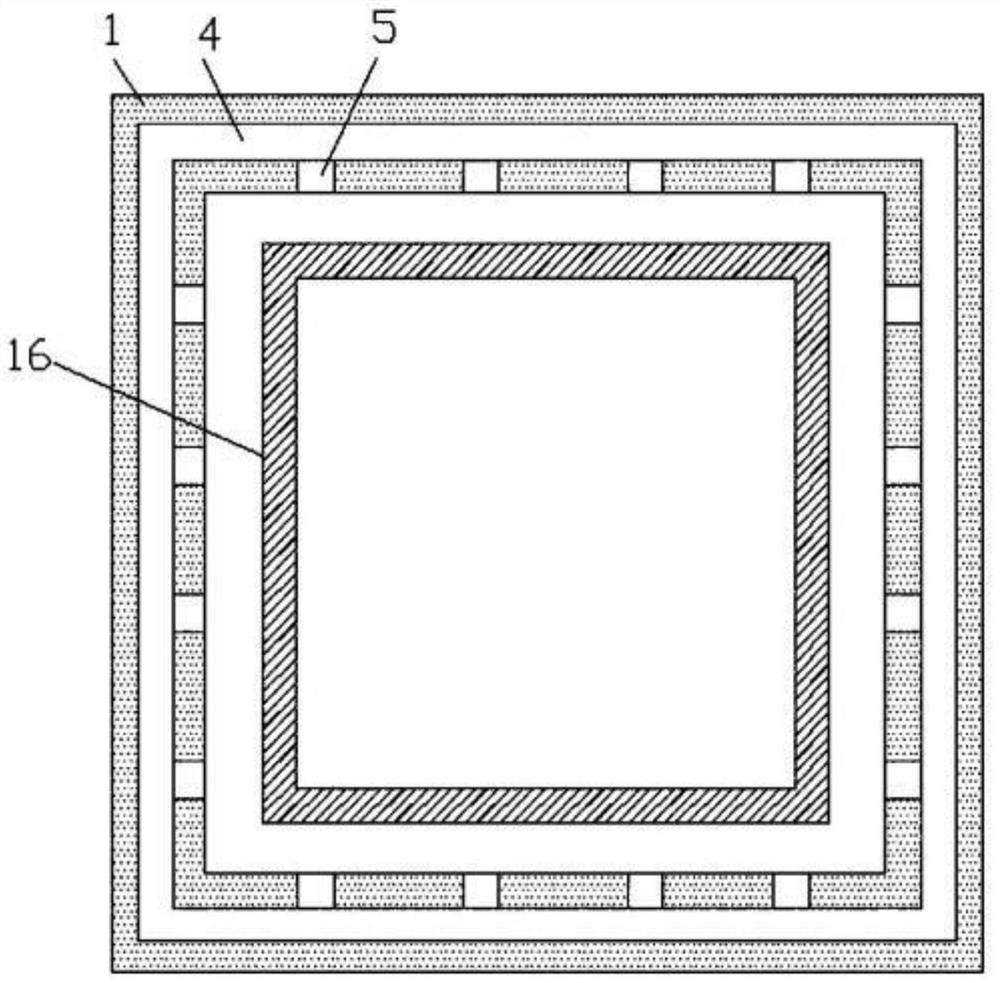

[0031] A heat dissipation device for electronic and electrical equipment, characterized in that it includes a heat dissipation cavity 1 and a cooling pipe 6; the heat dissipation cavity 1 has a cuboid structure, and the top surface of the heat dissipation cavity 1 is connected to the top cover 3 through a movable connection structure 2 to dissipate heat The chamber 1 has a double-layer structure, and a heat dissipation groove 4 is formed between the outer wall and the inner wall of the heat dissipation chamber 1. Several uniformly arranged ventilation holes 5 are arranged on the inner wall of the heat dissipation chamber 1. The bottom surface of the heat dissipation chamber 1 is provided with There are several evenly arranged cooling holes 14;

[0032] The heat dissipation cavity 1 is made of high thermal conductivity silica gel material, which is obtained by compounding organic silica gel and heat conduction material; the heat conduction material is composed of heat conduction...

Embodiment 2

[0049] A heat dissipation device for electronic and electrical equipment, characterized in that it includes a heat dissipation cavity 1 and a cooling pipe 6; the heat dissipation cavity 1 has a cuboid structure, and the top surface of the heat dissipation cavity 1 is connected to the top cover 3 through a movable connection structure 2 to dissipate heat The chamber 1 has a double-layer structure, and a heat dissipation groove 4 is formed between the outer wall and the inner wall of the heat dissipation chamber 1. Several uniformly arranged ventilation holes 5 are arranged on the inner wall of the heat dissipation chamber 1. The bottom surface of the heat dissipation chamber 1 is provided with There are several evenly arranged cooling holes 14;

[0050] The heat dissipation cavity 1 is made of high thermal conductivity silica gel material, which is obtained by compounding organic silica gel and heat conduction material; the heat conduction material is composed of heat conduction...

Embodiment 3

[0067] A heat dissipation device for electronic and electrical equipment, characterized in that it includes a heat dissipation cavity 1 and a cooling pipe 6; the heat dissipation cavity 1 has a cuboid structure, and the top surface of the heat dissipation cavity 1 is connected to the top cover 3 through a movable connection structure 2 to dissipate heat The chamber 1 has a double-layer structure, and a heat dissipation groove 4 is formed between the outer wall and the inner wall of the heat dissipation chamber 1. Several uniformly arranged ventilation holes 5 are arranged on the inner wall of the heat dissipation chamber 1. The bottom surface of the heat dissipation chamber 1 is provided with There are several evenly arranged cooling holes 14;

[0068] The heat dissipation cavity 1 is made of high thermal conductivity silica gel material, which is obtained by compounding organic silica gel and heat conduction material; the heat conduction material is composed of heat conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com