Automatic natural rubber collecting device for rubber

A natural rubber, automatic collection technology, applied in the fields of application, forestry, agriculture, etc., can solve the problems of heavy physical burden, low work efficiency, troublesome collection of natural rubber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

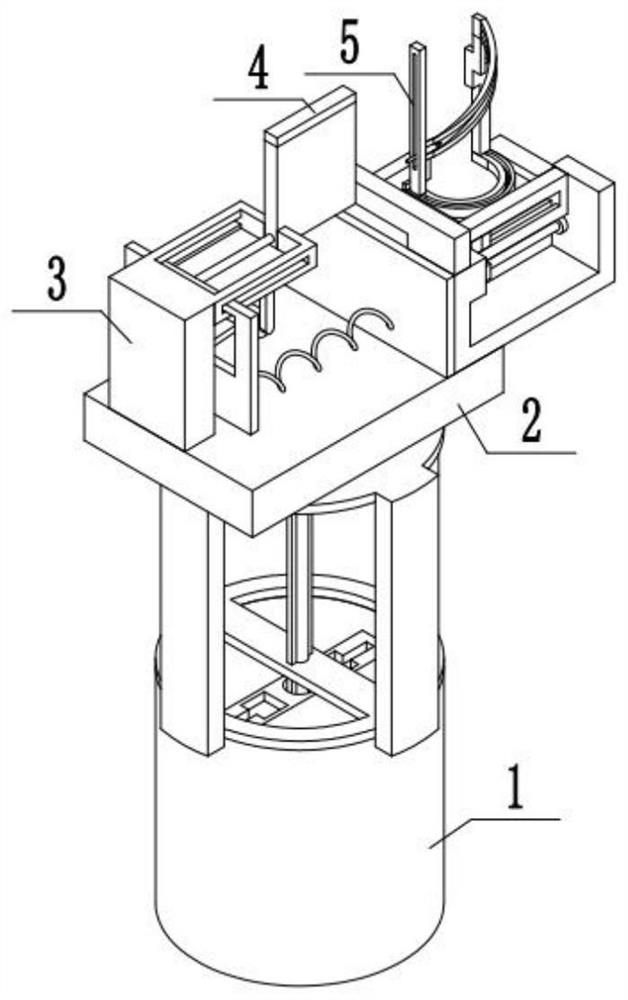

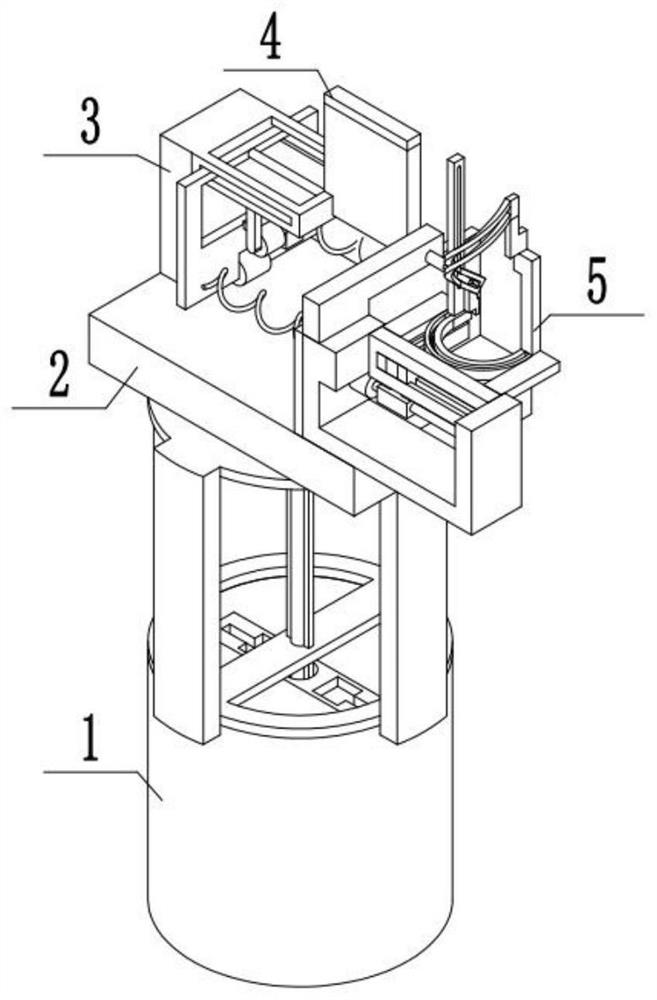

[0038] Combine below figure 1 , 2 Description of this embodiment, a natural rubber automatic collection device for rubber, including a height adjustment device 1, a mounting seat plate 2, a drainage tube insertion device 3, a drainage tube placement device 4 and a rubber tree cutting device 5, the height adjustment device 1 is fixedly installed with an installation seat plate 2, and a drainage tube driving device 3 is installed on the installation seat plate 2, and a drainage tube placement device 4 is fixedly installed on the drainage tube insertion device 3, and the drainage tube placement device 4 is fixedly installed on the rubber tree. On the cutting device 5, the rubber tree cutting device 5 is fixedly connected with the drainage tube driving device 3.

specific Embodiment approach 2

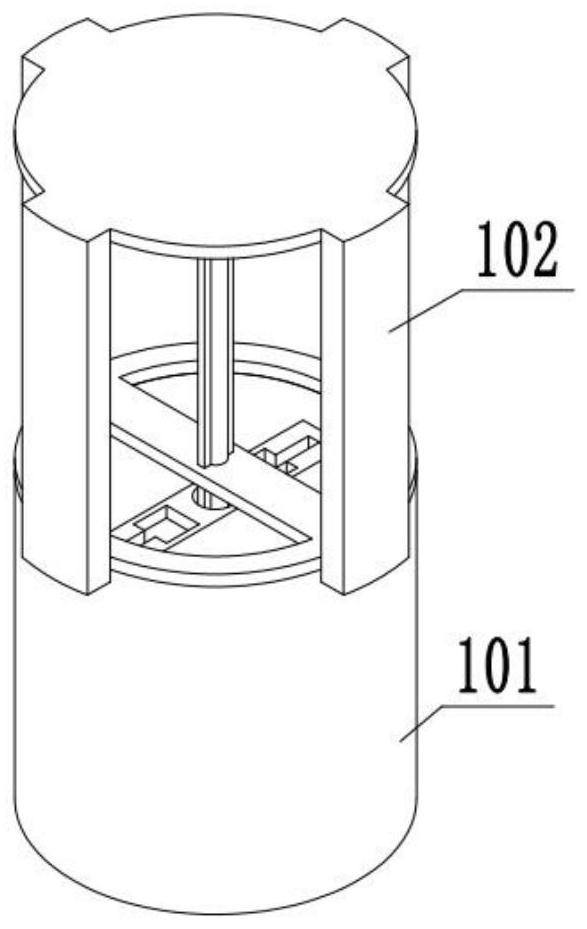

[0040] Combine below image 3 , 4 , 5, 6, 7, 8, and 9 illustrate this embodiment, and this embodiment will further explain Embodiment 1. The height adjustment device 1 includes a drive mechanism 101, a support upper frame body 102, and a support upper frame is installed on the drive mechanism 101. Body 102;

[0041] The driving mechanism 101 includes a fixed sleeve 103, an upper cover plate 104, a power motor A105, a feed screw 106, a support carriage 107, and a fixed slide plate 108. An upper cover plate 104 is fixedly installed above the fixed sleeve 103, and the power The motor A105 is fixedly installed on the fixed sleeve 103, the output end of the power motor A105 is equipped with a feed screw 106, the feed screw 106 is threaded with a support carriage 107, and the support carriage 107 is slidably installed on the fixed slide plate 108, The two ends of the support carriage 107 are slidably mounted on the fixed sleeve 103;

[0042] The support upper frame body 102 inclu...

specific Embodiment approach 3

[0044] Combine below Figure 10 , 11 Describe this embodiment, this embodiment will further explain Embodiment 1, the described drainage tube driving device 3 includes a fixed support plate 301, a spring A302, a rod driving plate 303, support wheels 304, an L-shaped frame 305, and a power motor B306, the fixed frame body 307, the drainage pipe rod 308, the fixed support plate 301 is fixedly installed on the installation seat plate 2, the two ends of the spring A302 are respectively fixedly installed on the fixed support plate 301 and the rod driving plate 303, and the rod drives the The plate 303 is fixedly installed with a drainage tube driving rod 308, and the supporting wheels 304 are movably installed on the driving board 303 for driving the rod. The type frame 305 is installed on the output end of the power motor B306, and the power motor B306 is fixedly installed on the fixed frame body 307, and the fixed frame body 307 is slidably installed with a rod driving plate 303...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com