Drilling device capable of preventing scraps from splashing

A drilling device and anti-chip technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problem of drilling position deviation, etc., to prevent debris from splashing, prevent splatter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

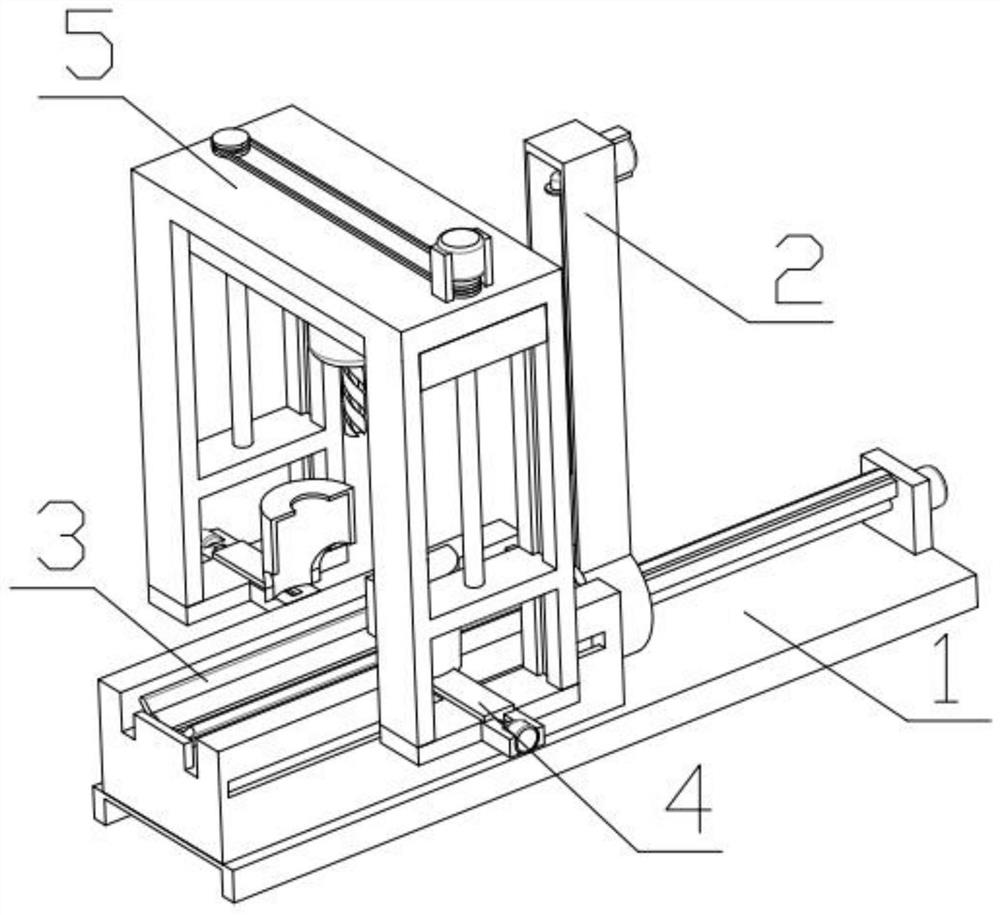

[0034] Combine below Figure 1-14 Description of this embodiment, a drilling device that prevents chips from flying around, including a distance-adjustable base 1, an adjustment blowpipe mechanism 2, a pipe diameter placement mechanism 3, an anti-splash mechanism 4, and a drilling mechanism 5. The adjustment blowpipe Mechanism 2 is threadedly connected to the distance-adjustable base 1, the pipe diameter placement mechanism 3 is fixedly installed on the distance-adjustable base 1, the splash-proof mechanism 4 is slidably installed on the distance-adjustable base 1, and the drilling mechanism 5 is fixedly installed on the splash-proof Institution 4 on.

specific Embodiment approach 2

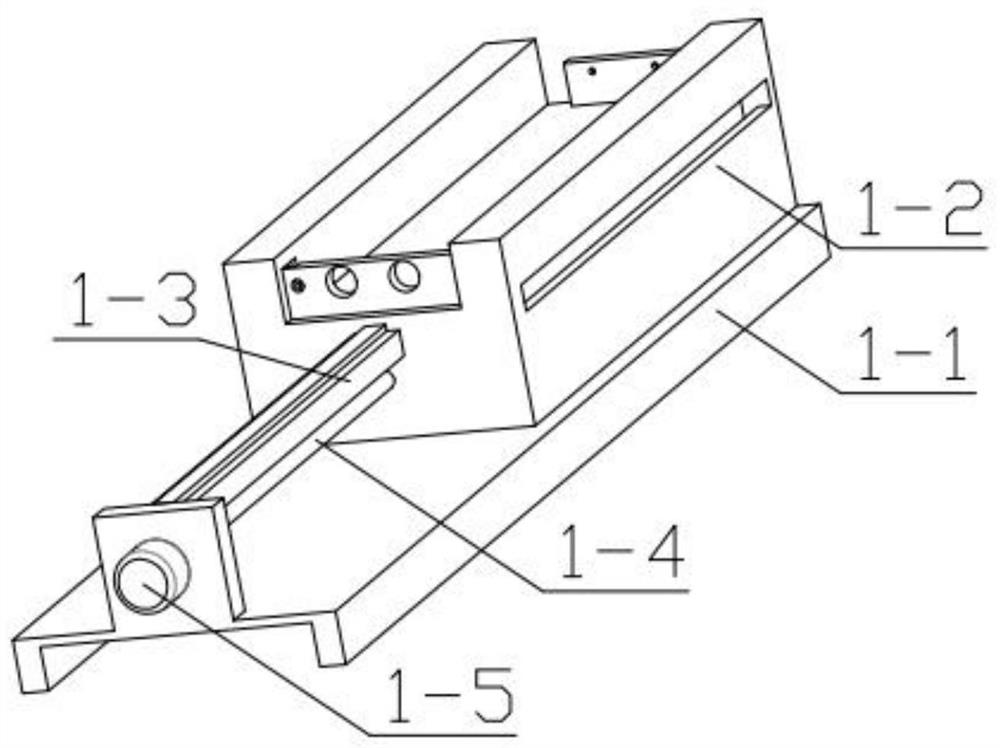

[0036] Combine below Figure 1-14Describe this embodiment, this embodiment will further explain Embodiment 1, the distance adjustable base 1 includes a base plate 1-1, a mounting seat 1-2, a track plate 1-3, an adjustment threaded rod 1-4, an adjustment The motor 1-5 and the adjusting motor 1-5 are fixedly installed on the base plate 1-1, the base plate 1-1 is fixedly installed with a mounting base 1-2, and the mounting base 1-2 is fixedly equipped with a track plate 1- 3. The other end of the track plate 1-3 is fixedly installed on the base plate 1-1, the output end of the adjusting motor 1-5 is fixedly installed with an adjusting threaded rod 1-4, and the other end of the adjusting threaded rod 1-4 is rotated and installed In the groove provided on the mounting base 1-2.

specific Embodiment approach 3

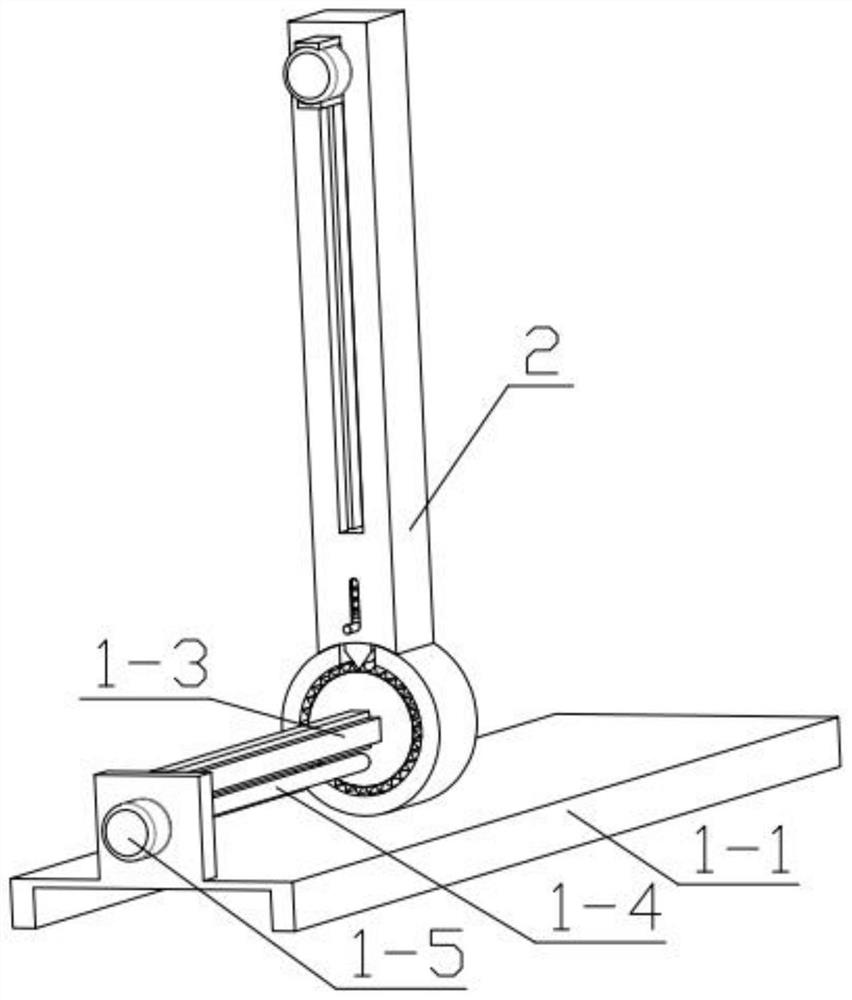

[0038] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain the second embodiment, the adjustment blow pipe mechanism 2 includes a grooved plate 2-1, a rotating ring 2-2, a positioning gear 2-3, and a triangular positioning member 2-4 , internal spring 2-5, fan 2-6, fan seat 2-7, sliding part 2-8, exhaust hose 2-9, positioning gear part 2-3 is slidably installed on track plate 1-3, positioning gear The part 2-3 is threadedly connected with the adjusting threaded rod 1-4, the positioning gear part 2-3 is rotatably installed with a rotating ring 2-2, and the rotating ring 2-2 is fixedly installed with a grooved plate 2-1 and a grooved plate 2 The triangular positioning part 2-4 is slidably installed in the groove of -1, the internal spring 2-5 is fixedly installed on the triangular positioning part 2-4, and the other end of the internal spring 2-5 is fixedly mounted on the groove plate 2-1 In the groove, a fan 2-6 is fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com