Visual inspection method for arc-shaped welding seam and adhesive tape

A visual inspection and glue strip technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as multiple errors, inability to maintain verticality, real-time robot pose errors, etc., to improve work efficiency and teaching process Simple, Complexity-Reduced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The visual detection method of arc-shaped welds and rubber strips includes two steps. First, a certain standard image to be tested needs to be taught, and then the same image can be detected:

[0046] 1. The teaching process includes the following steps:

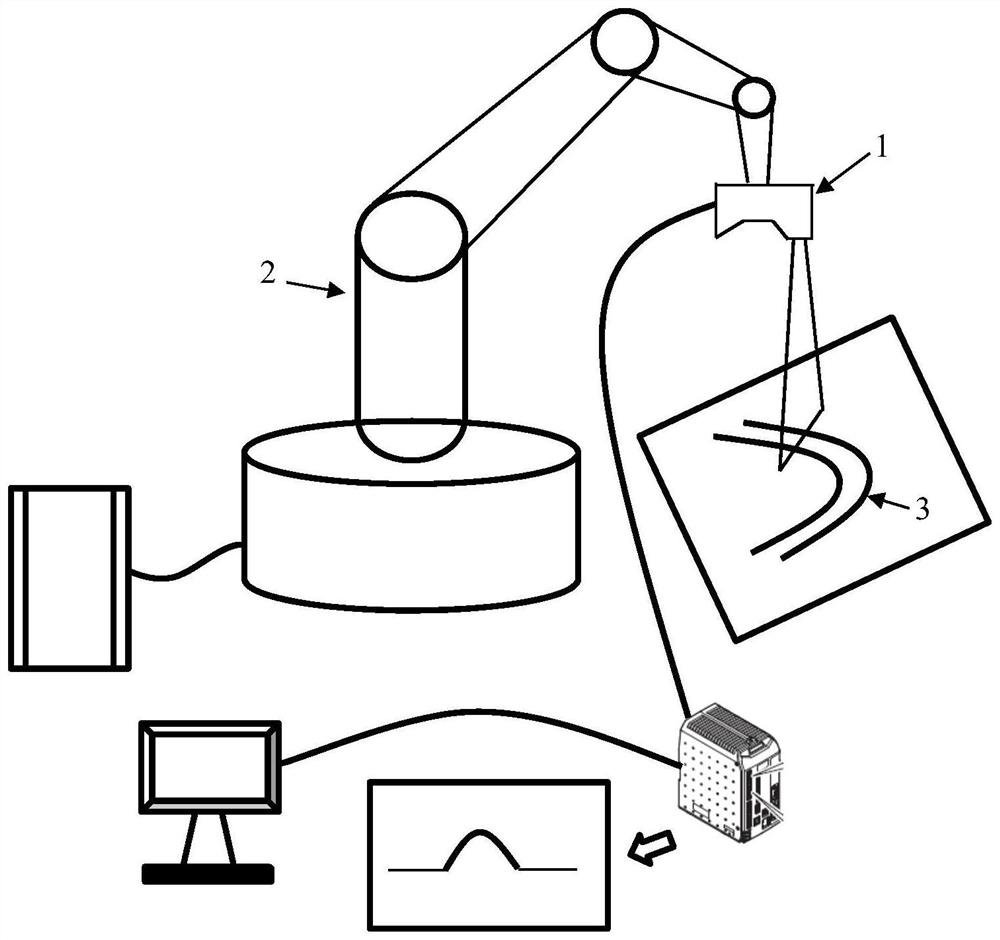

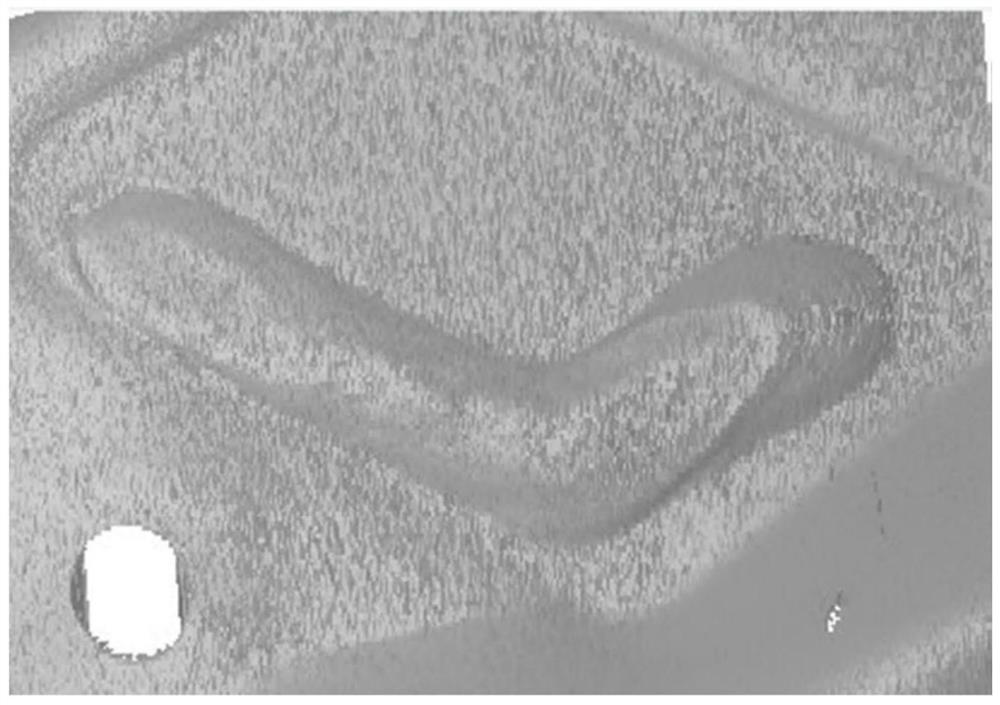

[0047]① Manually control the robot 2 with the structured light sensor 1 to scan the arc-shaped weld seam / glue strip 3 along a straight line trajectory, and obtain the point cloud image to be taught;

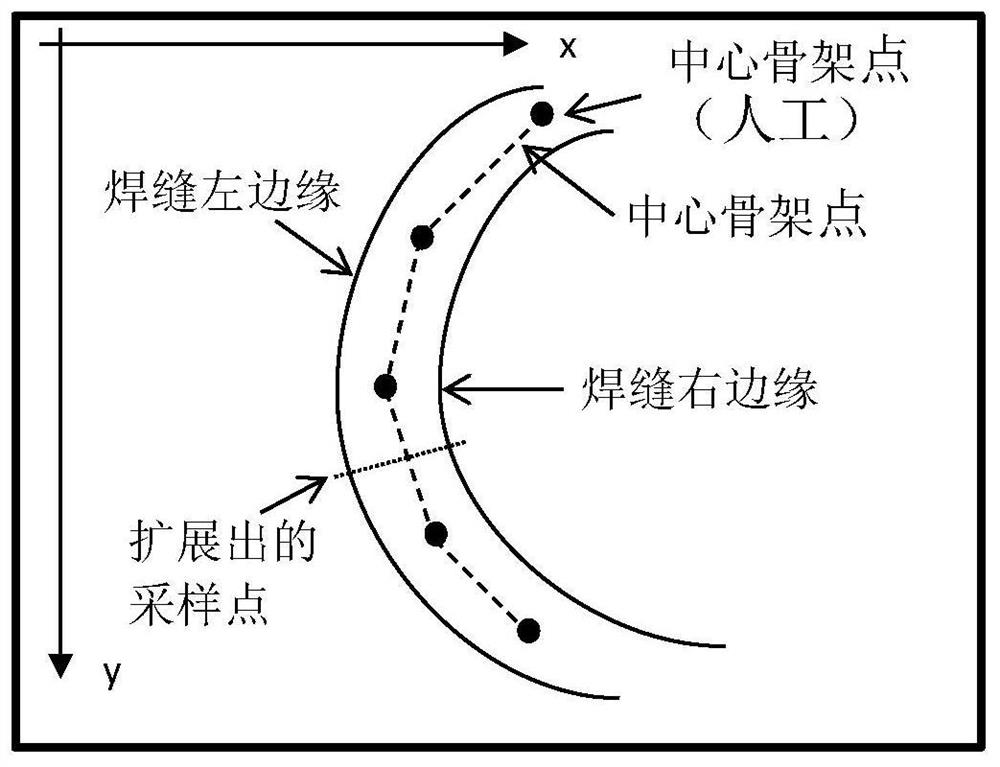

[0048] ② On the teaching point cloud image, mark the center skeleton point at the center line of the weld / glue strip along the length direction, and generate multiple center skeleton points with a step length A between two adjacent center skeleton points; obtain each Plane coordinates and height values of the central skeleton point;

[0049] ③ Take the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com