Printing detection and excess material detection device for 3D printer

A technology of 3D printers and detection devices, applied in manufacturing auxiliary devices, 3D object support structures, processing platforms/substrates, etc., can solve the problems of models that cannot be fully formed, printed models scrapped, waste of materials and time, etc., to achieve the overall structure Compact design, improved efficiency, convenient and multi-directional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

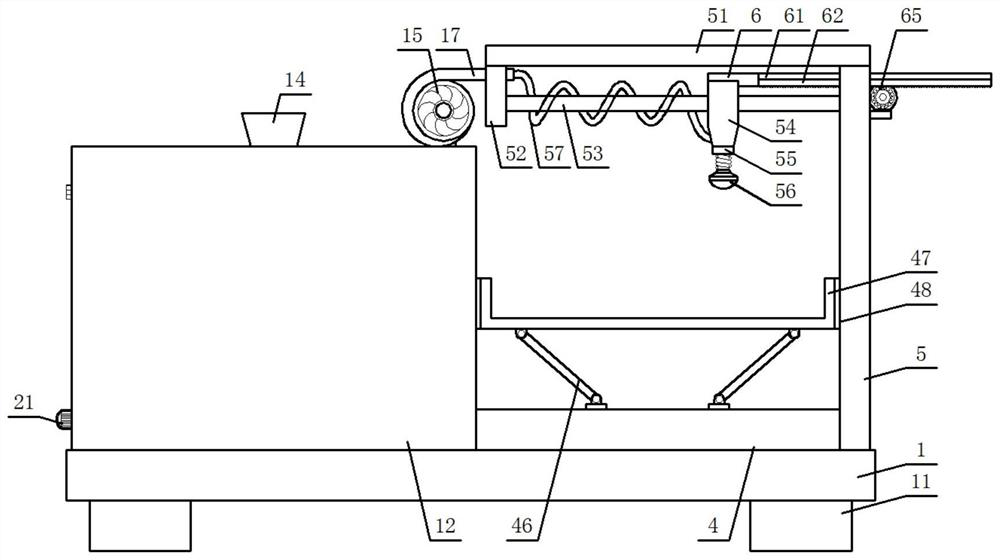

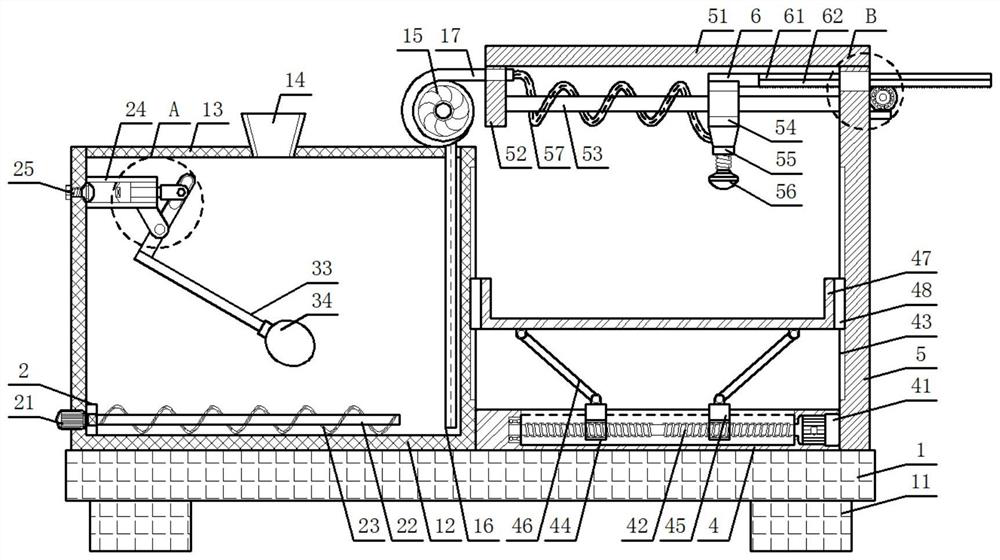

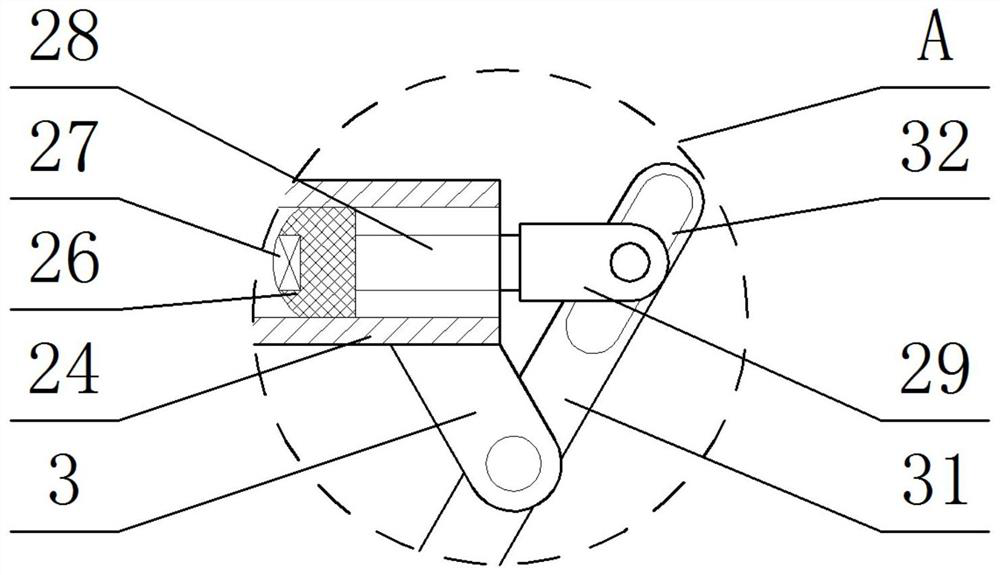

[0028] Embodiment 1: see Figure 1-4 , a printing detection and remaining material detection device based on a 3D printer, including a bottom plate 1, a detection component, a heating component, a lifting mechanism, and a material spraying mechanism. Bases 11 are provided at the four corners of the bottom surface of the bottom The side is provided with the material box 12 that is horizontally fixed, and the top surface opening of material box 12 is provided with the cover plate 13 that horizontally fixedly connects, and the top surface middle part of cover plate 13 is provided with conical material barrel 14, and the left side of material box 12 A detection component is installed on the top of the wall, and a heating component is installed on the inner bottom of the material box 12;

[0029] The right side of the top surface of the base plate 1 is provided with a horizontally affixed rectangular box 4, which is located on the right side of the rectangular box 4. On the right e...

Embodiment 2

[0035] Embodiment 2: In this embodiment, the present invention also proposes a detection method based on a 3D printer-based printing detection and residual material detection device, including the following steps:

[0036] Step 1, the high-pressure pump 15, the heater 21, the induction switch 25, the screw motor 41, and the meshing motor 64 are respectively electrically connected to the external power supply through the power line, and the induction threshold is set in the induction switch 25. When the induction block 27 exceeds the induction threshold, Inductive switch 25 reports to the police;

[0037] Step 2: Add printing materials into the material box 12 through the tapered material cylinder 14, and start the heater 21 to heat the printing materials into a heating stock solution, and start heating the heating rod 22 under the action of the heater 21, The heating rod 22 transfers heat to the heating wire 23 and heats the printing material, and the heating effect of the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com