Modularized multi-stage-area mineralization metallurgy pressurization mineralization system

A pressurized system and modular technology, applied in metallurgical wastewater treatment, chemical instruments and methods, water treatment parameter control, etc., can solve the problems of limited dissolved air, large footprint, low air flotation separation efficiency, etc., to achieve high Effect of Hydrophobic Mineralization Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. In order to more clearly illustrate the embodiments of the present patent or the technical solutions in the prior art, the following drawings will be used in the description of the embodiments or the prior art. From a brief introduction, it is obvious that the accompanying drawings in the following description are only some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained from these drawings without creative efforts. .

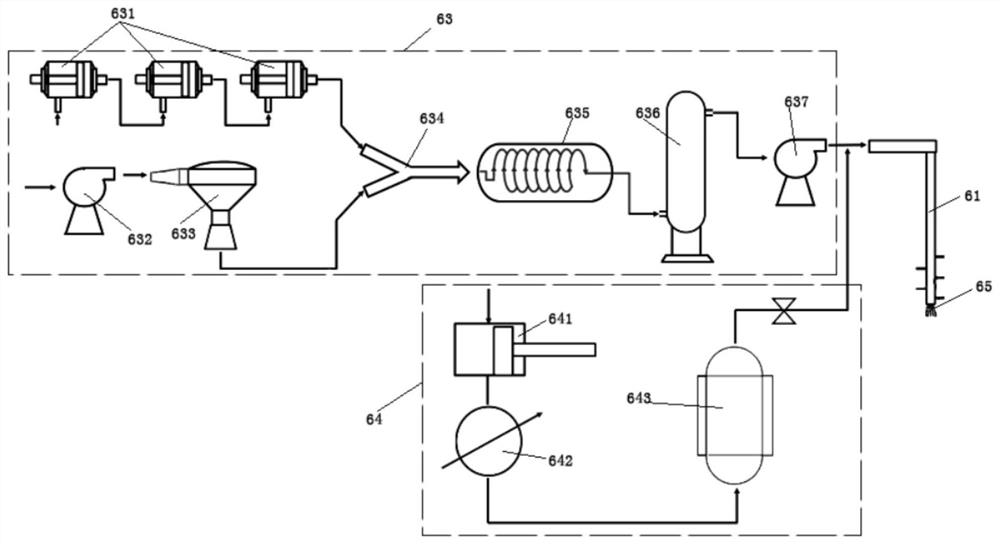

[0022] like figure 1 As shown in the figure, a modular multi-stage zone mineralization metallurgy pressurization mineralization system includes a feed liquid pressurization system 63, a supercritical CO 2 The fluid-assisted dissolved gas system 64 and the microbubble cloud production system, the feed-liquid booster system 63 includes a gas feed booster assembly and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com