Ceramic device and preparation method thereof

A technology for ceramics and devices, applied in the field of ceramic devices and their preparation, can solve the problems of low dimensional accuracy, large shrinkage rate, sintering deformation, etc., and achieve the effects of high surface flatness and strong shrinkage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

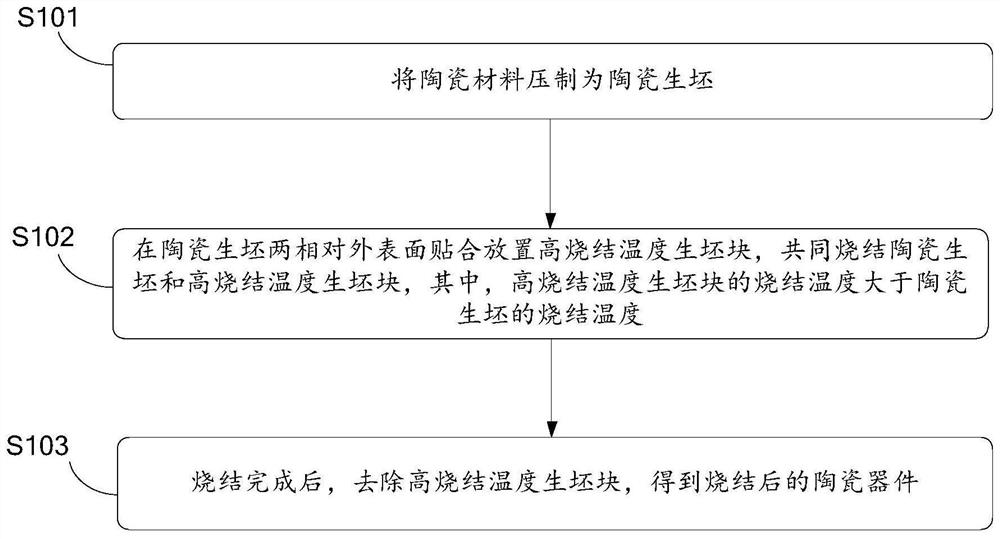

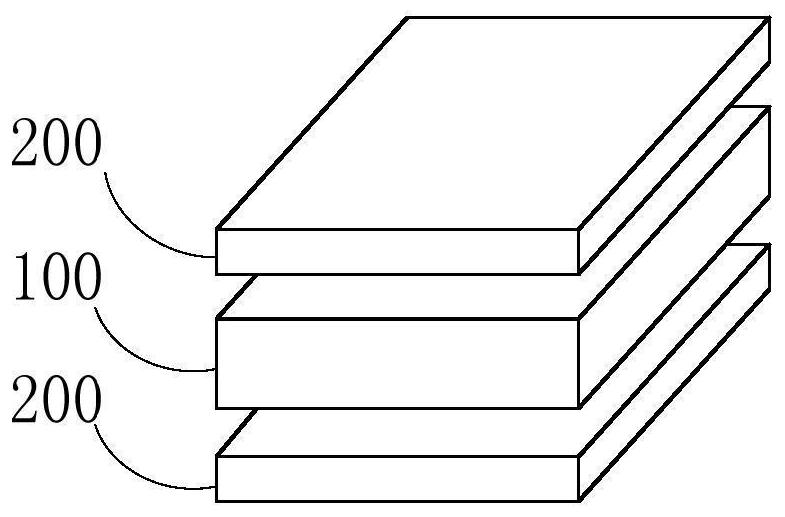

[0014] An embodiment of the present application provides a method for preparing a ceramic device, comprising the following steps:

[0015] S101 : pressing the ceramic material into a ceramic green body 100 .

[0016] Specifically, a ceramic material is put into a mold, and the ceramic material is pressed into a ceramic green body 100 under a predetermined pressure. Wherein, the predetermined pressure is 120MPa˜160MPa, for example, 120MPa, 130MPa, 140MPa, 150MPa or 160MPa, etc., which is not limited here. The ceramic material in this embodiment includes Al 2 o 3 , MgO, La 2 o 3 , in other embodiments, the preparation method of the ceramic device is applicable to most ceramic materials.

[0017] Specifically, the ceramic material is Al 2 o 3 , MgO, La 2 o 3 Mixed and ground composite powder. In other embodiments, the ceramic material is a composite powder formed by mixing and grinding a ceramic matrix and glass powder, wherein the ceramic matrix is Al 2 o 3 , MgO, ...

Embodiment 1

[0070] The ceramic matrix in the microwave dielectric ceramic material provided by this embodiment is 22Al 2 o 3 -3MgO-2La 2 o 3 , the glass powder is Al 2 o 3 -SiO 2 -B 2 o 3 , and the quality of the glass powder accounts for 0.25% of the mass of the ceramic matrix, and the Al with a purity of more than 99% 2 o 3 , MgO, La 2 o 3 , SiO 2 and B 2 o 3 As the starting material, and prepared by the following process steps.

[0071] A. First prepare the ceramic matrix material, according to the general chemical formula 22Al 2 o 3 -3MgO-2La 2 o 3 , calculate the quality of each raw material needed, the raw material adopts analytical pure, the MgO of 99wt% and the La of 99.9wt% 2 o 3 and Al 2 o 3 ;

[0072] B. Pour the accurately weighed raw materials into the ball mill tank, add deionized water and ZrO 2 Grinding balls; the weight ratio of the three is: material: balls: deionized water = 1:2:1.5; ball milling for 4 hours, after mixing evenly, discharge the mat...

Embodiment 2

[0087] The ceramic matrix in the microwave dielectric ceramic material provided by this embodiment is 22Al 2 o 3 -3MgO-2La 2 o 3 , the glass powder is ZnO-SiO 2 -B 2 o 3 , and the quality of the glass powder accounts for 0.10% of the mass of the ceramic matrix, and the Al with a purity of more than 99% 2 o 3 , MgO, La 2 o 3 , ZnO, SiO 2and B 2 o 3 As the starting material, and prepared by the following process steps.

[0088] A. First prepare the ceramic matrix material, according to the general chemical formula 22Al 2 o 3 -3MgO-2La 2 o 3 , calculate the quality of each raw material needed, the raw material adopts analytical pure, the MgO of 99wt% and the La of 99.9wt% 2 o 3 and Al 2 o 3 ;

[0089] B. Pour the accurately weighed raw materials into the ball mill tank, add deionized water and ZrO 2 Grinding balls; the weight ratio of the three is: material: balls: deionized water = 1:2:1.5; ball milling for 4 hours, after mixing evenly, discharge the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com