Method for reducing carbon pollution in molten salt electrolysis process

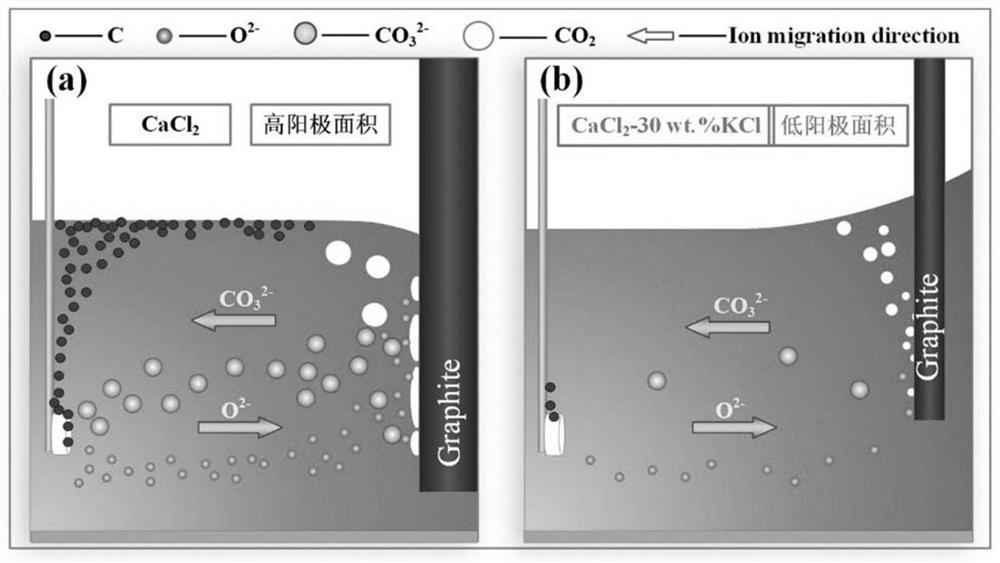

A molten salt electrolysis and carbon pollution technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of shortening the life of the anode, increasing the content of carbon impurities, and reducing the current efficiency, so as to improve the pollution of molten salt and reduce the product Carbon content, the effect of avoiding the risk of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

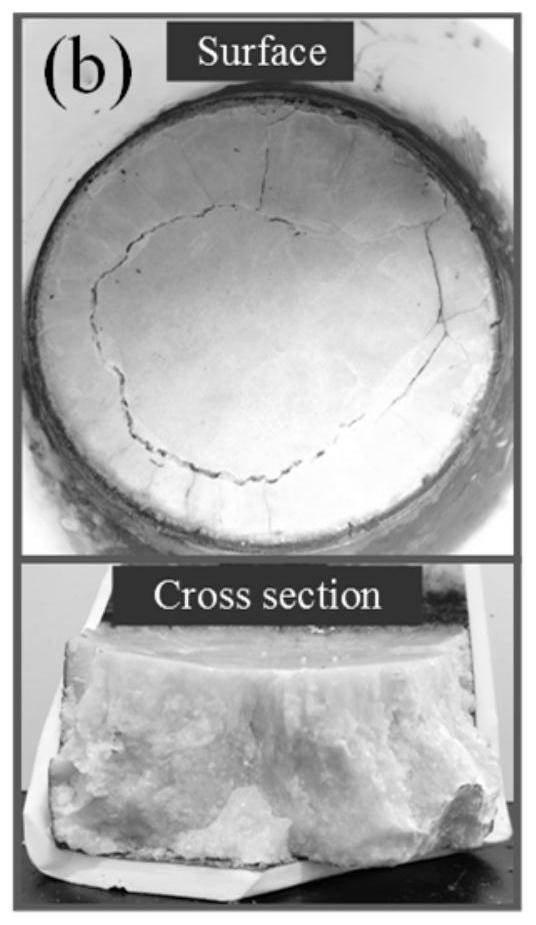

[0031] This embodiment selects CaCl 2 -30wt% KCl is molten salt, and a graphite rod with a diameter of 10mm is used as the anode, indicating that the molten salt modification has an inhibitory effect on carbon pollution. The steps are as follows:

[0032] 1) Weigh 1.5g TiO 2 The powder was wrapped with a 300-mesh stainless steel mesh as the cathode.

[0033] 2) Add CaCl 2 Mix with KCl molten salt at a mass ratio of 7:3 and dry at 150°C for 12 hours;

[0034] 3) TiO wrapped with stainless steel mesh 2 The powder is suspended on a steel electrode rod with a metal wire as the cathode, and a graphite rod with a diameter of 10 mm as the anode, CaCl 2 -30 wt.% KCl mixed molten salt as molten salt;

[0035] 4) The electrolysis is carried out in the tubular electrolysis furnace, and the air in the furnace is exhausted by repeated vacuuming and argon gas before electrolysis. After cleaning the furnace, argon gas is continuously fed into the furnace to ensure an inert atmosphere. ...

Embodiment 2

[0041] This embodiment selects CaCl 2 -50wt% KCl is molten salt, and a graphite rod with a diameter of 10mm is used as the anode, indicating that the molten salt modification has an inhibitory effect on carbon pollution. The steps are as follows:

[0042] 1) Weigh 1.5g TiO 2 The powder was wrapped with a 300-mesh stainless steel mesh as the cathode.

[0043] 2) Add CaCl 2 Mix with KCl molten salt at a mass ratio of 1:1 and dry at 150°C for 12 hours;

[0044] 3) TiO wrapped with stainless steel mesh 2 The powder is suspended on a steel electrode rod with a metal wire as the cathode, and a graphite rod with a diameter of 10 mm as the anode, CaCl2 -30 wt.% KCl mixed molten salt as molten salt;

[0045] 4) The electrolysis is carried out in the tubular electrolysis furnace, and the air in the furnace is exhausted by repeated vacuuming and argon gas before electrolysis. After cleaning the furnace, argon gas is continuously fed into the furnace to ensure an inert atmosphere. T...

Embodiment 3

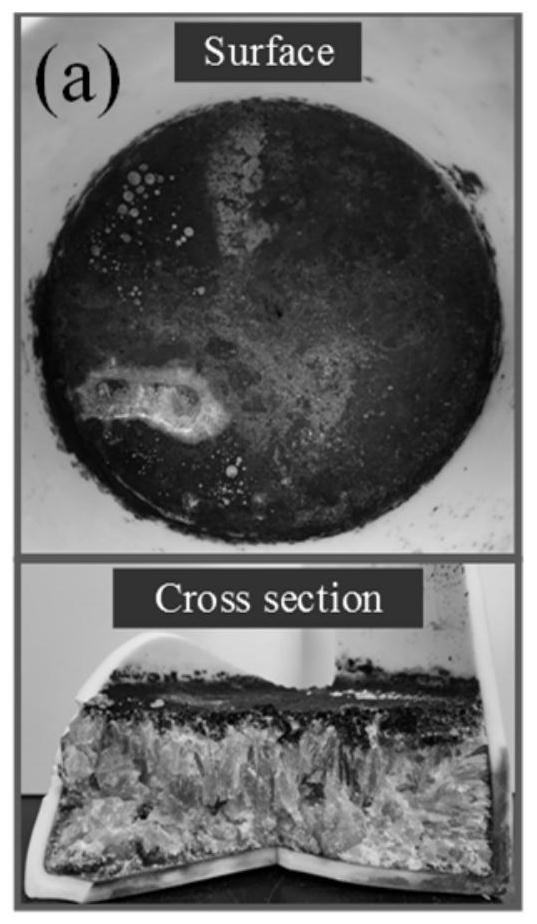

[0051] This embodiment selects CaCl 2 For the molten salt, a graphite rod with a diameter of 10mm is used as the anode, and the depth of immersion in the molten salt is 0.5mm (the area of the anode is 2.36cm 2 ). To demonstrate the inhibitory effect of reducing the anode area on carbon contamination in the cathode product, the steps are as follows:

[0052] 1) Weigh 1.5g TiO 2 The powder was wrapped with a 300-mesh stainless steel mesh as the cathode.

[0053] 2) Add CaCl 2 Dry the molten salt at a temperature of 150°C for 12 hours;

[0054] 3) TiO wrapped with stainless steel mesh 2 The powder is suspended on a steel electrode rod with a metal wire as the cathode, and a graphite rod with a diameter of 10 mm as the anode, CaCl 2 as molten salt;

[0055] 4) The electrolysis is carried out in the tubular electrolysis furnace, and the air in the furnace is exhausted by repeated vacuuming and argon gas before electrolysis. After cleaning the furnace, argon gas is continu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap