Construction supporting formwork and construction process for hyperboloid wood grain fair-faced concrete roof

A technology of fair-faced concrete and construction technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of difficult construction of hyperbolic roofs and difficulty in meeting construction requirements with formwork support systems, and achieves Reduce construction difficulty, ensure safety, and ensure the effect of molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

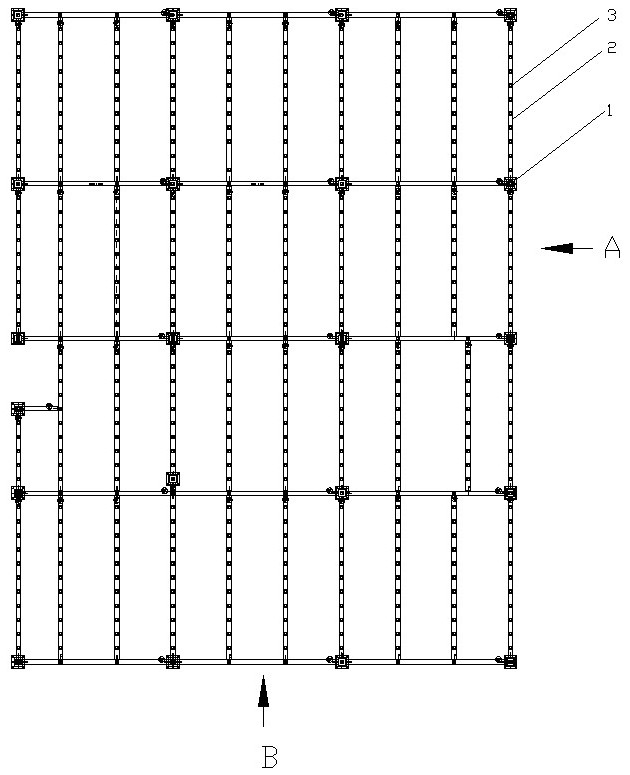

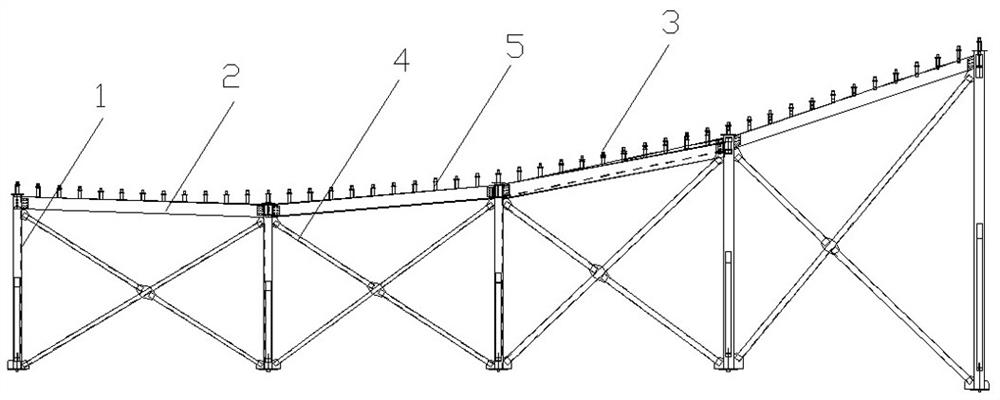

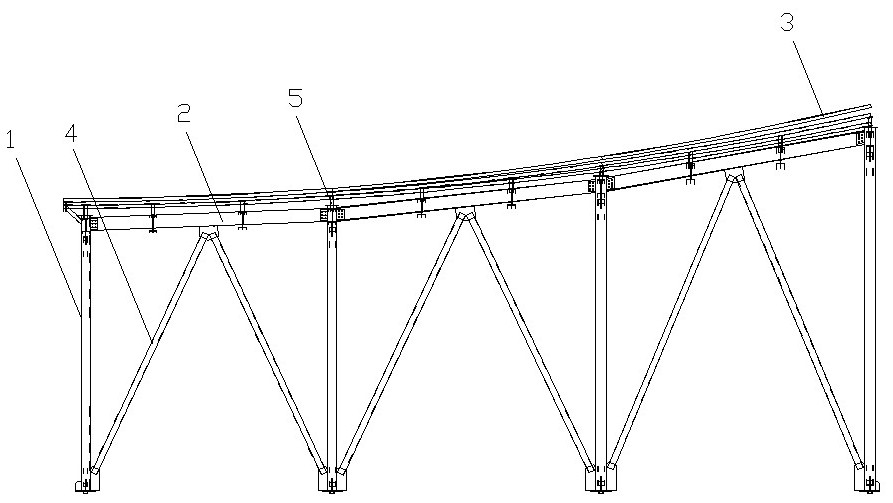

[0033] As shown in the figure, the hyperboloid wood-grain fair-faced concrete roof construction support formwork includes a roof support system and a roof formwork.

[0034] The roof support system is composed of multiple square columns 1 with different heights, multiple I-beams 2, and multiple arc-shaped main keels 3. According to the specific conditions of the construction site, the multiple square columns 1 avoid the distribution of the wall and are placed on the bottom surface. The construction foundation is poured in advance, and the square column and the construction foundation are fixed by embedded bolts.

[0035] The tops of adjacent square columns 1 are installed with bolts to form I-beams 2 to form a stable support, and the adjacent square columns 1 are connected and reinforced by a pair of intersecting diagonal brace beams 4 . Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com