Cluster well group oil production well chemical adding and associated gas recovery device

A recovery device and technology for oil production wells, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve problems such as increased operational risk, pollution, inconvenience in operation, etc., to reduce management risks, high safety factor, and operational handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

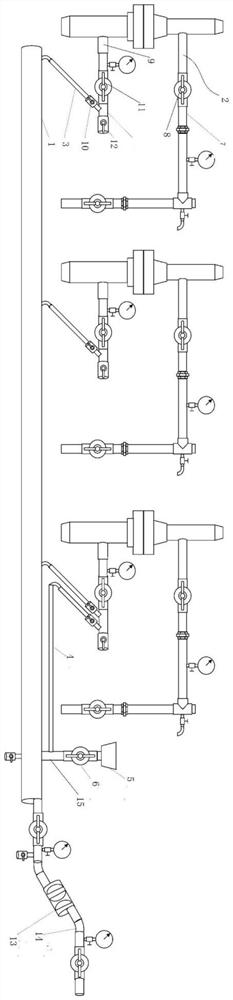

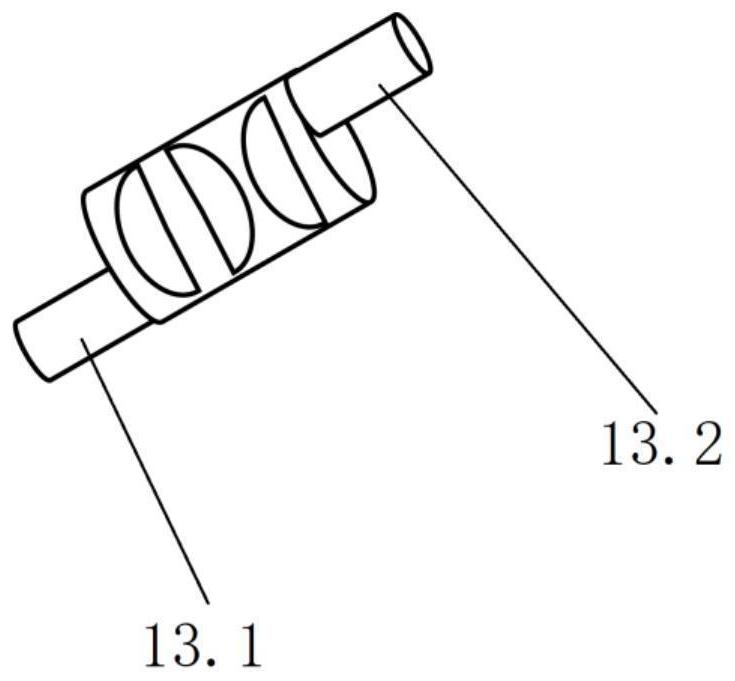

[0020] Attached below figure 1 and 2 The present invention is described in further detail.

[0021] A cluster well group oil production well dosing and associated gas recovery device, comprising a gas-gathering dosing manifold 1 and a number of gas-gathering units 2 arranged on the manifold 1, wherein the gas-gathering unit 2 near one end of the manifold 1 It communicates with it through a single well dosing gas collection pipe 3, and the gas collection unit 2 close to the other end of the manifold 1 communicates with it through a gas phase balance pipe 4, and a gas-liquid separation mechanism is provided at the end of the manifold 1 near the balance pipe 4 ; The balance pipe 4 is also provided with a dosing funnel 5 communicating with the manifold 1;

[0022] During normal gas collection, the oil well casing associated gas is collected through the single well dosing gas collection pipeline and the dosing gas collection manifold, and the condensate is separated by the baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com