Multifunctional variable-section lining trolley for tunnel and using method thereof

A lining trolley, multi-functional technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of lining trolley steering construction, troublesome track erection, poor positioning accuracy, etc., to improve construction efficiency, accurate and stable positioning , The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

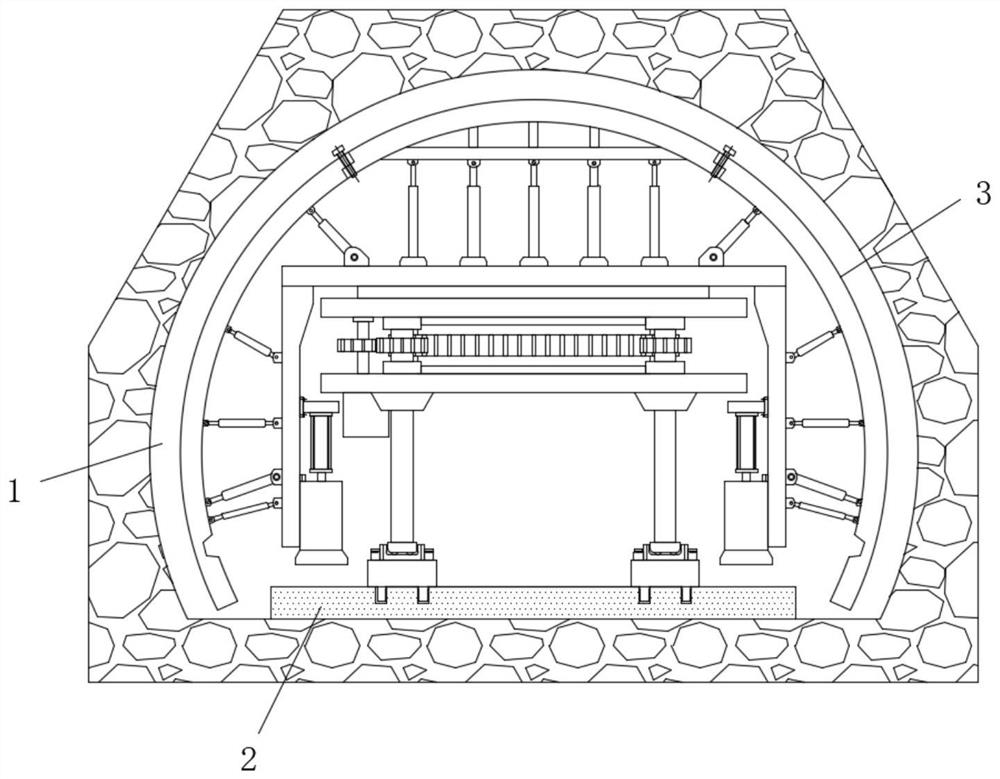

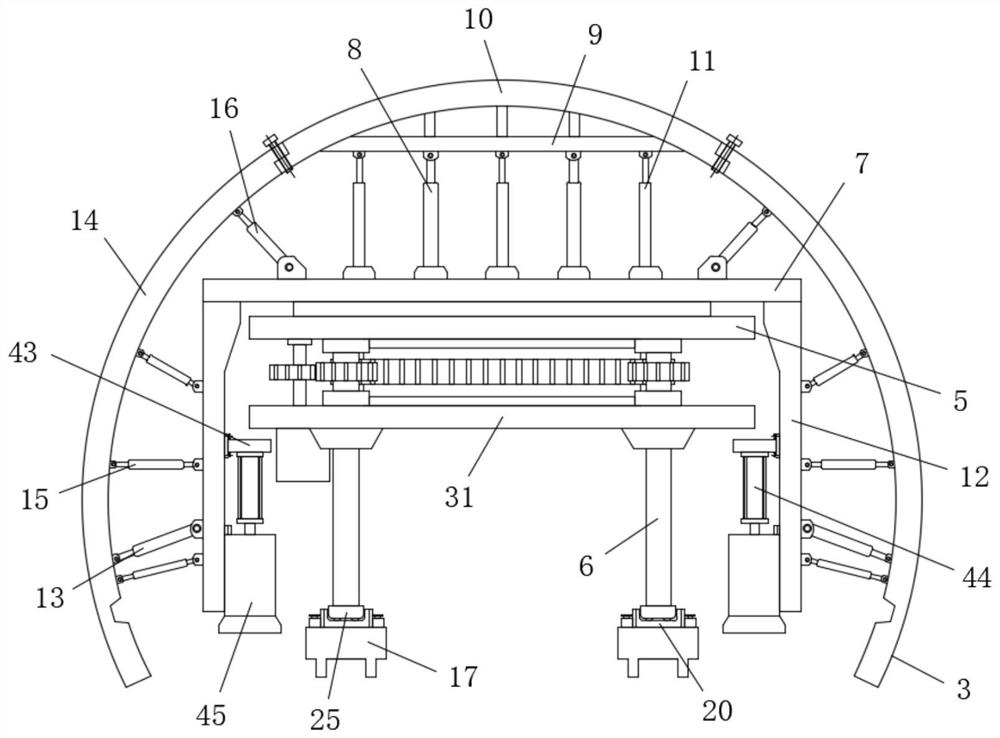

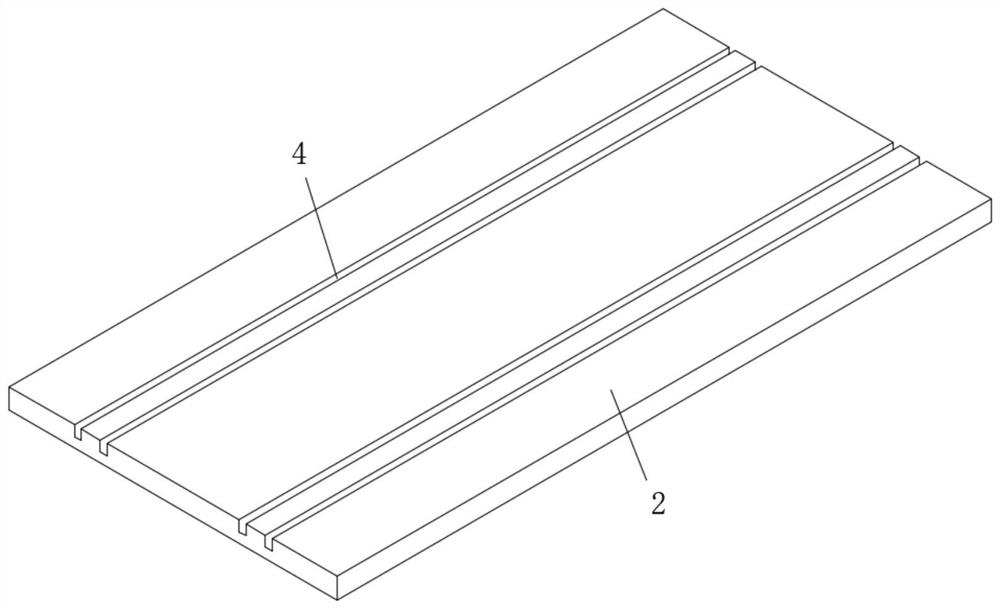

Embodiment 1

[0061] Such as Figure 1-15 As shown, a tunnel multi-functional variable section lining trolley includes a tunnel 1, a track laying platform 2 extended and laid on the ground inside the tunnel 1, and a lining trolley 3 slidingly connected to the track laying platform 2. The lining trolley 3 includes the upper round table 5, the bottom of the upper round table 5 is rotatably connected with four columns 6 arranged in a square, the bottom ends of the four columns 6 are provided with traveling mechanisms, and the top of the track laying platform 2 is provided with two sets of track mechanisms side by side. And the four running gears are divided into two groups and are slidably connected on the same track mechanism respectively. The top of the upper round table 5 is supported and rotated to be connected with a support plate 7, and the bottom of the support plate 7 is symmetrically provided with two arc-shaped chute 42. The top of the top is fixedly connected with a support slip rin...

Embodiment 2

[0071] This embodiment is as a further improvement of the previous embodiment: as Figure 1-15 As shown, a tunnel multi-functional variable section lining trolley includes a tunnel 1, a track laying platform 2 extended and laid on the ground inside the tunnel 1, and a lining trolley 3 slidingly connected to the track laying platform 2. The lining trolley 3 includes the upper round table 5, the bottom of the upper round table 5 is rotatably connected with four columns 6 arranged in a square, the bottom ends of the four columns 6 are provided with traveling mechanisms, and the top of the track laying platform 2 is provided with two sets of track mechanisms side by side. And the four running gears are divided into two groups and are slidably connected on the same track mechanism respectively. The top of the upper round table 5 is supported and rotated to be connected with a support plate 7, and the bottom of the support plate 7 is symmetrically provided with two arc-shaped chute 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com