Automobile oil-gas separation valve

A separation valve, oil and gas technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of high crankcase pressure, air leakage and oil leakage at joints, affecting engine performance, etc., to prolong transmission time and improve filtration. effect, the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

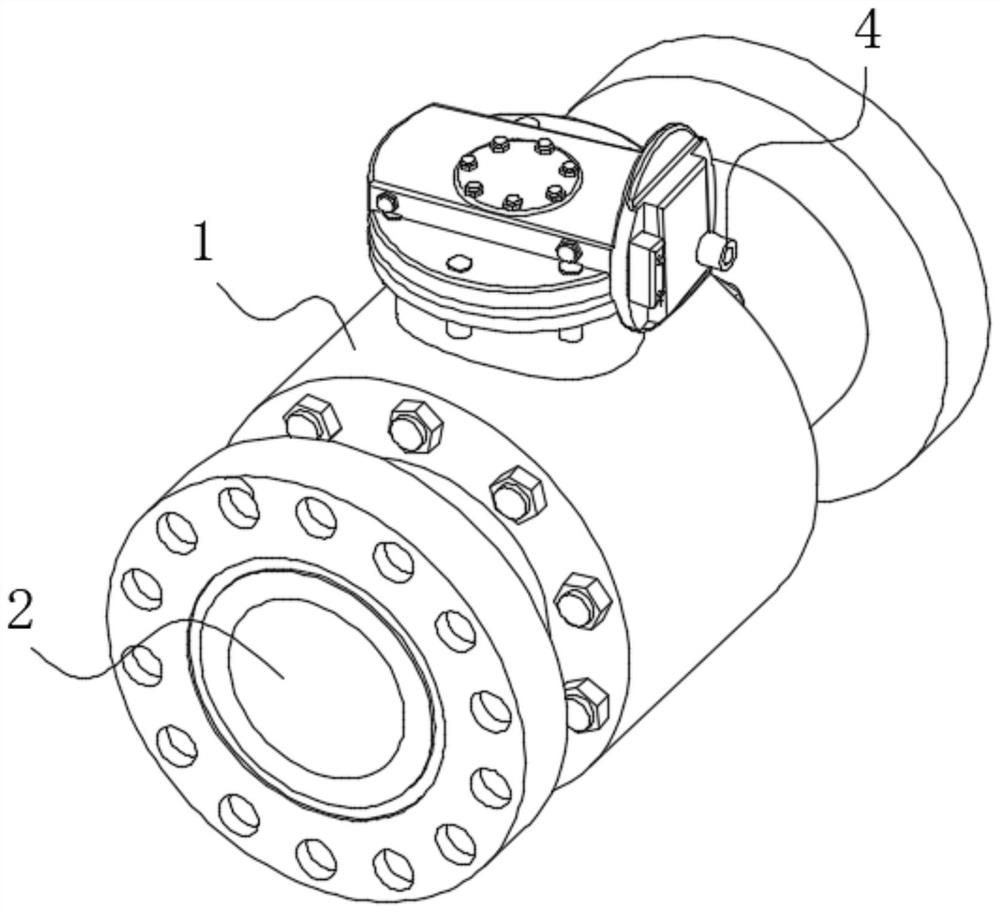

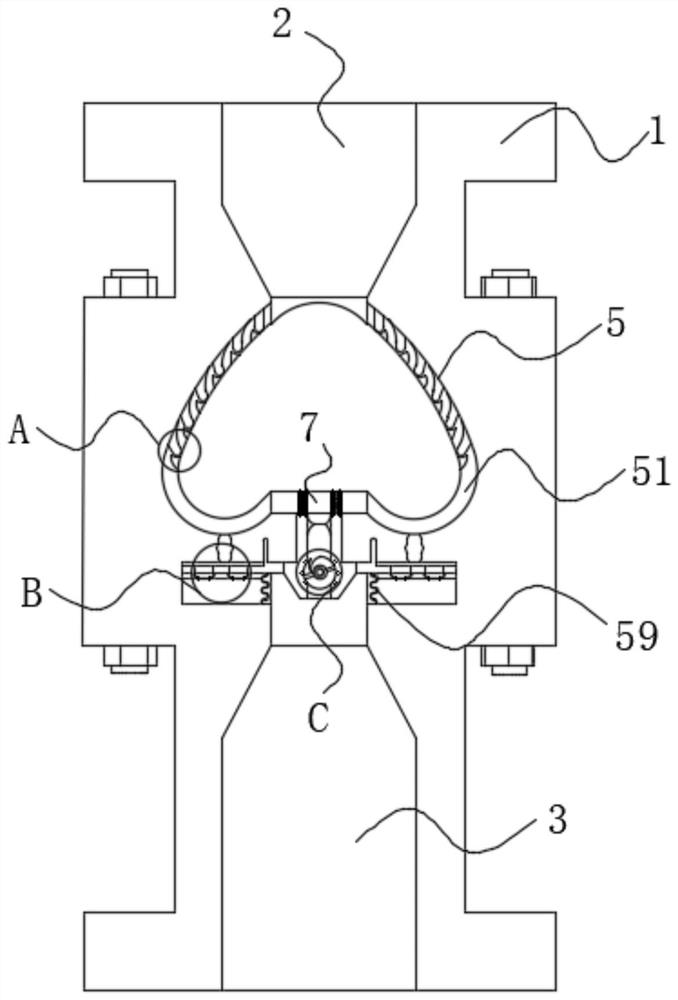

[0021] use Figure 1-Figure 5 An automotive oil-air separation valve according to one embodiment of the present invention will be described below.

[0022] Such as Figure 1-Figure 5As shown, a kind of oil-gas separation valve for automobiles according to the present invention comprises valve body 1, air inlet hole 2, air outlet hole 3, oil-gas pipe 4 and separation mechanism 5; An air hole 2, an air outlet hole 3 is provided in the lower end wall of the valve body 1, and an oil and gas pipe 4 is fixedly connected to the outer wall of the middle part of the valve body 1; the air inlet hole 2 communicates with the air outlet hole 3 through a separation mechanism 5; the separation The mechanism 5 communicates with the oil and gas pipe 4 .

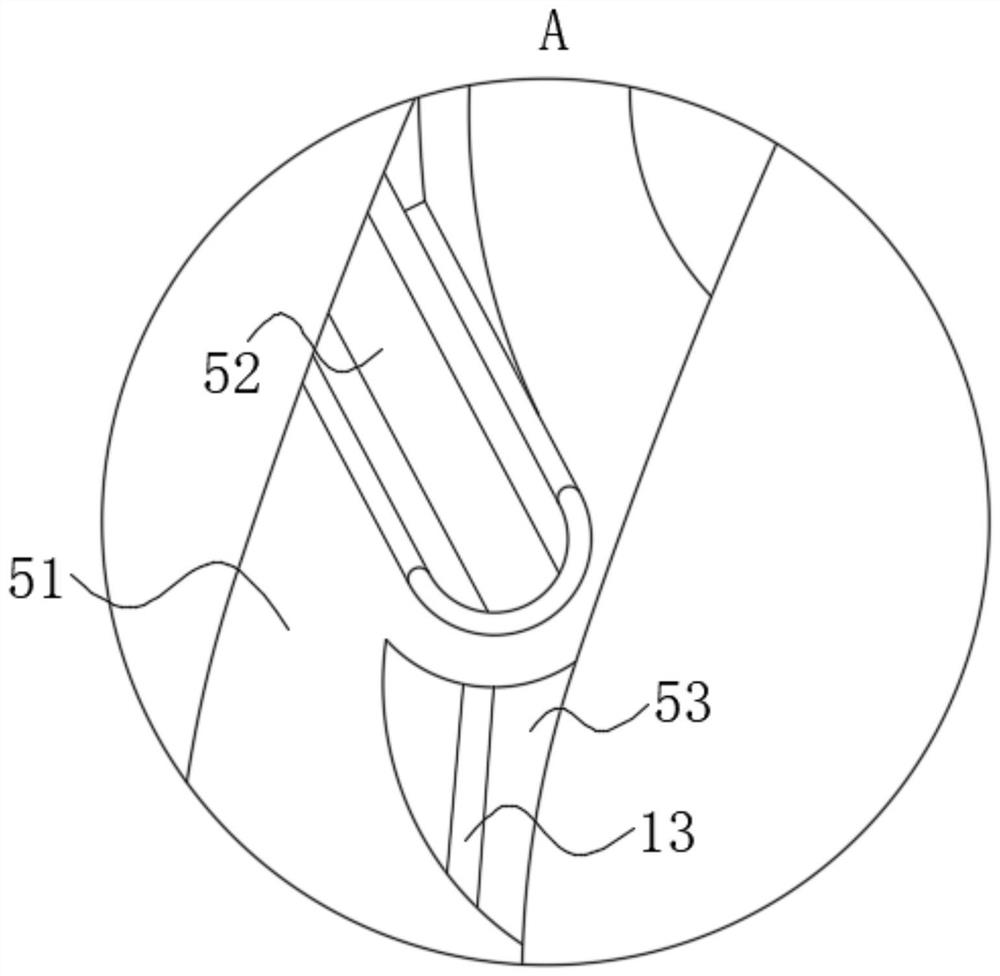

[0023] Described separation mechanism 5 comprises dredge hole 51, filter plate 52, deflector 53, communication groove 54, collection tank 55, extruding plate 56, liquid flow groove 57, sponge ring 58 and bellows 59; The hole 51 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com