Strip lamp and manufacturing method of strip lamp

A manufacturing method and strip light technology, which are applied to the semiconductor devices of light-emitting elements, lighting devices, light sources, etc., can solve the problems of cumbersome, multi-assembly process of strip light structure parts, etc., to simplify the assembly process, simplify the structure, and reduce the quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

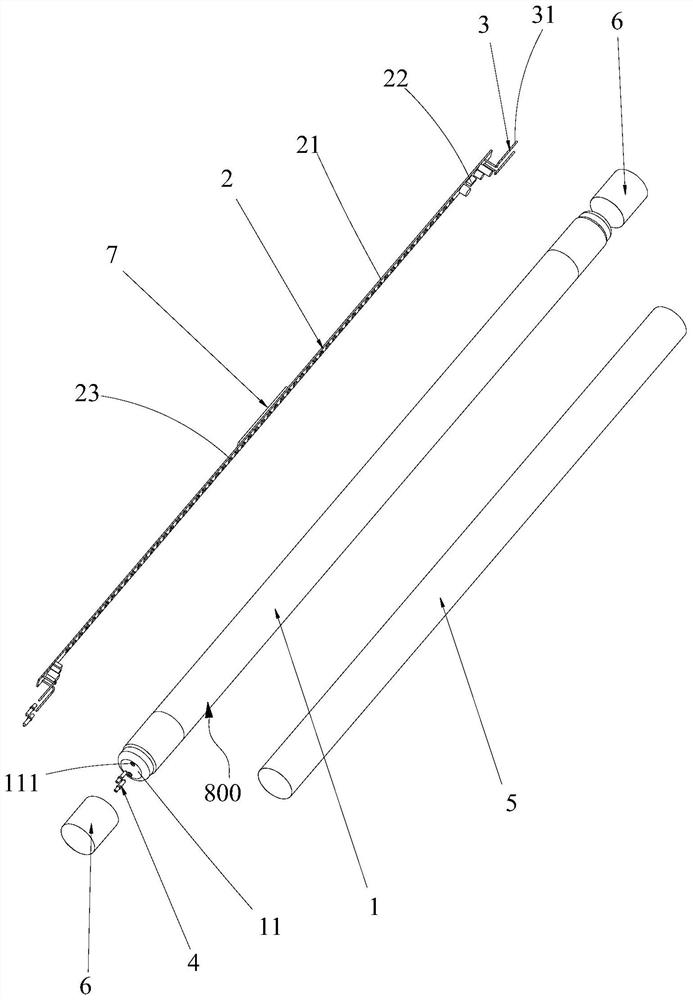

[0075] Further, see Figure 5 , as another specific embodiment of the manufacturing method of the strip light provided in the present application, the lamp tube 1 is a glass tube 800, and step S400 specifically includes the following steps:

[0076] S401, fixing the position of the metal wire 3 by a jig;

[0077] S403, heat and soften the openings of the two ends of the glass tube 800 (can be heated by spraying fire);

[0078] S404. After the two ends of the glass tube 800 are softened, clamp the softened part of the glass tube 800 and use the softened part to seal the opening of the glass tube 800, and make the softened part adhere to the metal wire 3, and Make the metal wire 3 extend out of the glass tube 800;

[0079] S405, forming the lamp cap 11 after cooling the softened part.

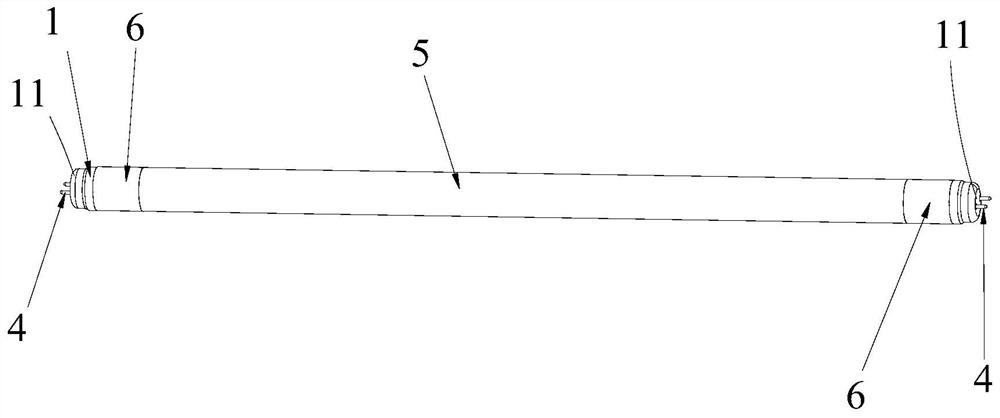

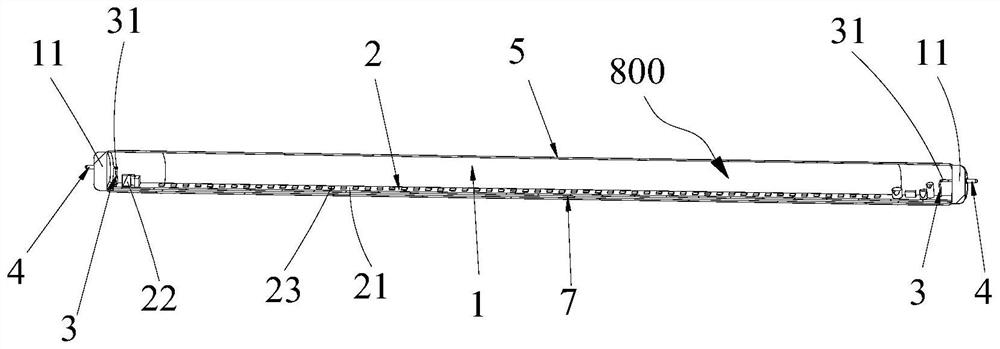

[0080] Please also refer to Figure 1-Figure 3 , that is, the lamp cap 11 is a "part" of the lamp tube 1. The lamp tube 1 is set as a glass tube 800, and the glass tube 800 is softened and cl...

Embodiment approach

[0081] Further, see Figure 5 , as another specific embodiment of the manufacturing method of the strip light provided in the present application, the metal wire 3 is a copper needle, and before step S403, the following steps are also included:

[0082] S402 , sleeve the molybdenum needle 4 on the outside of the metal wire 3 .

[0083] Please also refer to Figure 4 , when both the lamp tube 1 and the lamp cap 11 are glass parts, that is, the lamp tube 1 is a glass tube 800; when the lamp tube 1 and the lamp cap 11 are integrally formed, since the lamp cap 11 is formed of a glass part and bonded to the surface of the metal wire 3, The metal wire 3 is a copper needle, and the shrinkage rate of the copper needle and the glass material is different, so the glass is easy to crack when the copper needle is heated and expanded. The shrinkage ratio of the molybdenum material and the glass material is almost the same, so that the outer wall of the molybdenum needle 4 is set in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com