A snow-making method for a snow-making machine suitable for a positive temperature environment

A snow making and environment technology, applied in the field of snow making by snow making machines, can solve the problems of large air cooling energy consumption and low cooling capacity utilization efficiency of the blower, and achieve the advantages of rapid heat dissipation, high cooling capacity utilization efficiency, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

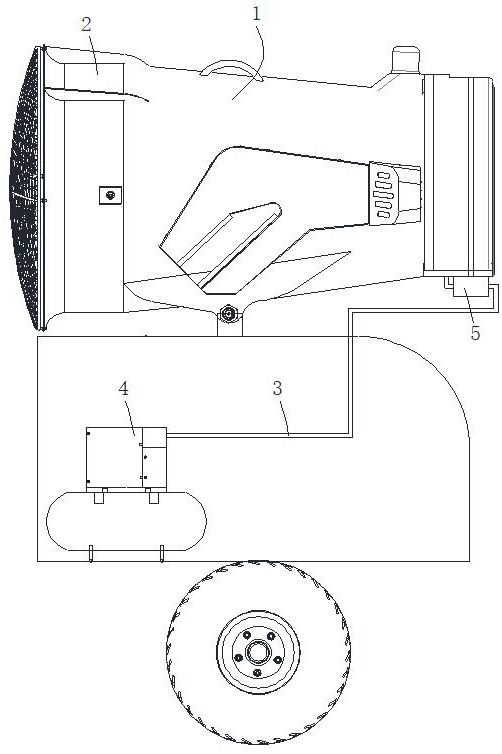

[0050] Specific implementation method: a snowmaking method suitable for a positive temperature environment. In the snowmaking machine, high-pressure water and high-pressure air are mixed and then sprayed out through a nucleator to form small-sized snow nuclei, and then the high-pressure water After being atomized and ejected from the nozzle, it is combined with the impact of the snow core to form snowflakes, and then rely on the wind blown by the blower to make the snowflakes spray out to realize snowmaking. Perform pre-cooling to lower the temperature so that its temperature is lower than zero degrees Celsius, and then pass through the nucleator and high-pressure water to mix and form a snow nucleus to be ejected.

[0051] Like this, in this method, by cooling the high-pressure air, after the high-pressure water and high-pressure air enter the mixing chamber where the nuclear device is located and mix, the temperature of the mixed fluid is greatly reduced. Even if the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com