Double-sided alignment fitting precision detection system

A precision detection and fitting technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as insufficient light, reduced photo clarity, and positioning failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

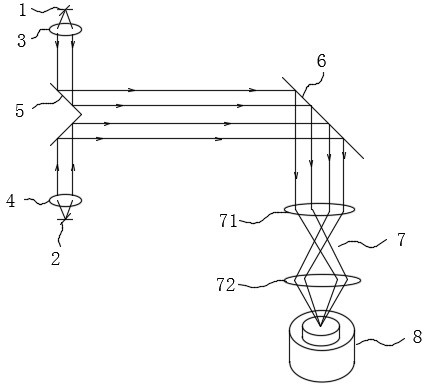

[0025] Example 1, such as figure 2 As shown, the present invention provides a double-sided alignment and bonding accuracy detection system, including: a light collimation device, an optical path conversion device, and an imaging device. Collimating device 2, the light collimating device 1 and the light collimating device 2 are used to collimate divergent light into parallel light; the optical path conversion device is arranged between the light collimating device 1 and the light collimating device 2 In between, the optical path conversion device is used to adjust the angle of the light collimated by the light collimating device 1 and the light collimating device 2 so that the emitted light is parallel to the collimated light; the imaging device is set On one side of the optical path conversion device, the imaging device is used to receive the light emitted by the optical path conversion device for imaging.

[0026] In an embodiment of the present invention, the light collima...

Embodiment 2

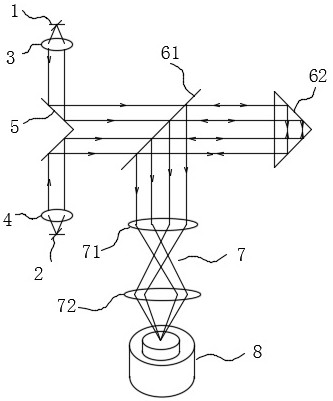

[0029] Example 2, such as image 3As shown, the present invention provides another double-sided aligning and adhering accuracy detection system. The difference from Embodiment 1 is that the light deflection element 2 includes a half mirror 61 and a triangular prism 62. The half mirror The reflection mirror 61 can direct the light emitted by the first reflection mirror 5 to the triangular prism 62 , and can also deflect the light reflected by the triangular prism 62 by 90 degrees and emit it to the imaging device. Specifically, the triangular prism 62 includes a transmission surface, a reflection surface 1, and a reflection surface 2, a certain angle is formed between the reflection surface 1 and the reflection surface 2, and the transmission surface faces the half mirror 61; it can be understood that the triangular prism 62 is an isosceles right-angle triangular prism, that is to say, the included angle between the first reflecting surface and the second reflecting surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com