Single-camera double-spherical-mirror image binocular vision measurement system and method

A binocular vision measurement, dual spherical technology, applied in the field of vision measurement, can solve the problem of small field of view, and achieve the effect of expanding the field of view, expanding the scope of application, and easy to reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

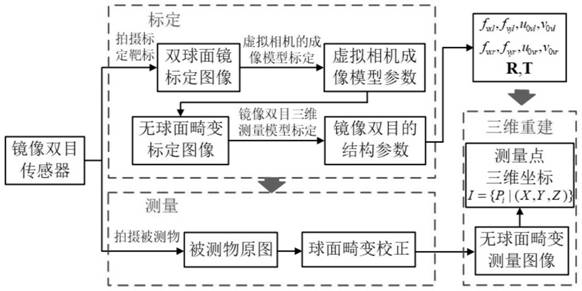

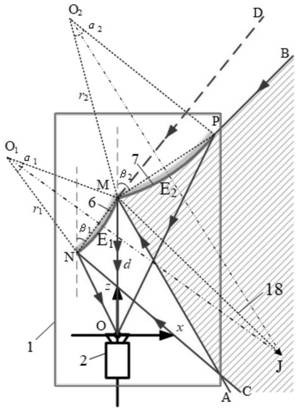

[0046] The present invention will be described in further detail below. The present invention is based on computer vision and image processing technology, according to the paper "Three-Dimensional Measurement Approach in SmallFOV and Confined Space Using an Electronic Endoscope [J]. IEEE Sensors Journal, 2014, 14 (9): 3274-3282." The two-plane mirror single-camera mirroring binocular stereo vision system was proposed, based on this improvement, the mirror binocular vision sensor composed of a single-camera and a double-spherical mirror was designed, and the imaging model of the virtual camera was established. The spherical curl distortion image captured by the mirror binocular sensor is unfolded, that is, the distortion is corrected, and the mirror binocular 3D measurement model is established, and the 3D measurement is realized after the calibration of each model parameter is completed.

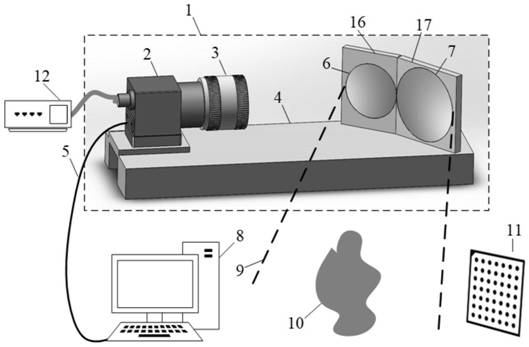

[0047] The structure of the mirror binocular sensor and the optical path design of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com