On-line monitoring method for fastener looseness based on transformer vibration characteristics

A technology of fasteners and transformers, which is applied in the testing of machine/structural components, testing of mechanical components, and measurement of torque/torsional force during tightening. It can solve problems such as large numerical values and large excitation inrush currents, and achieve accurate measurement results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

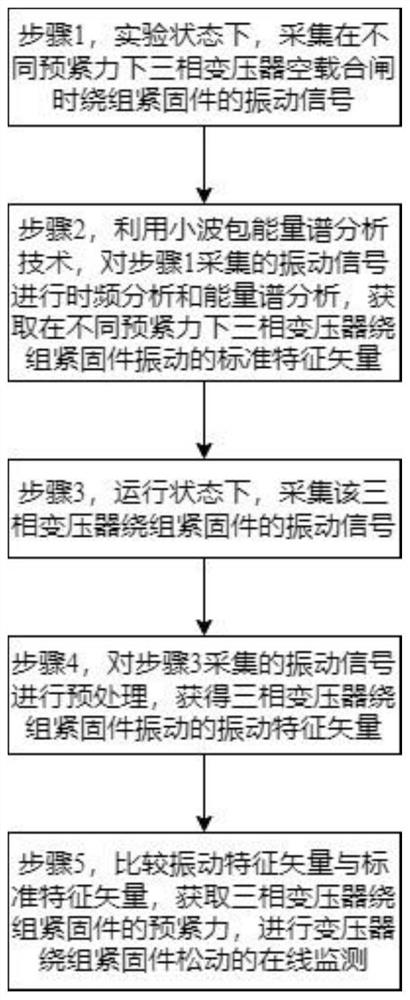

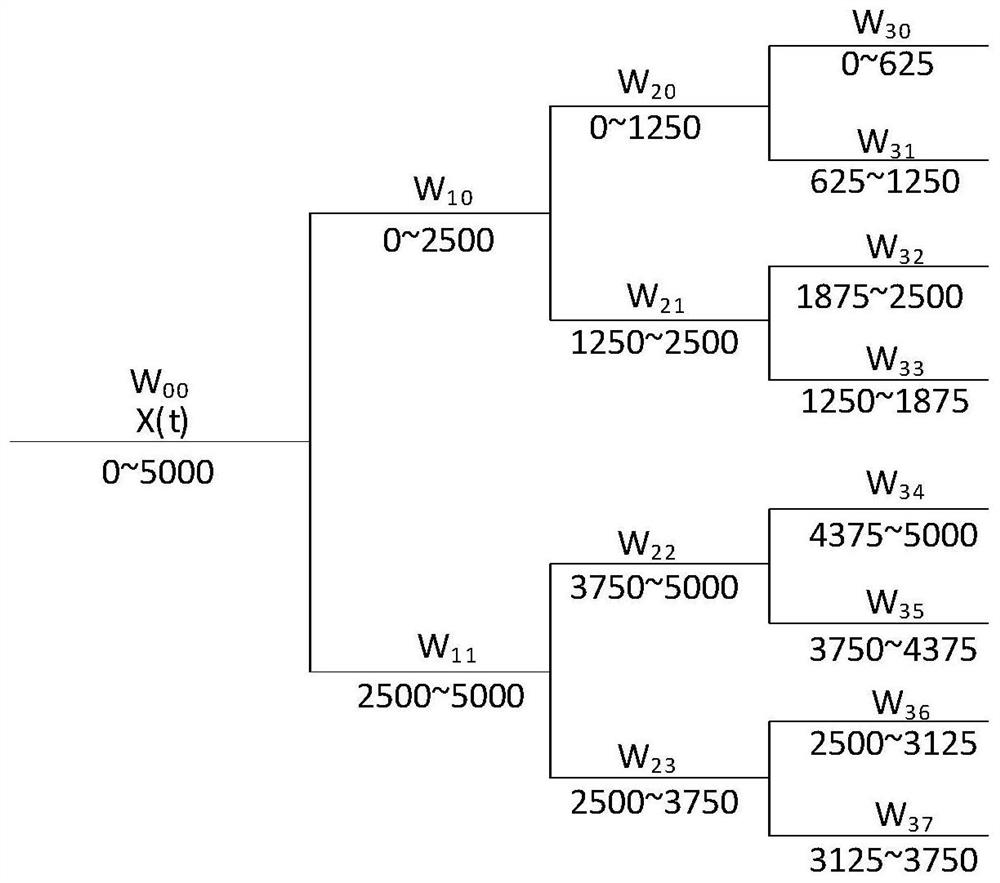

[0058] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

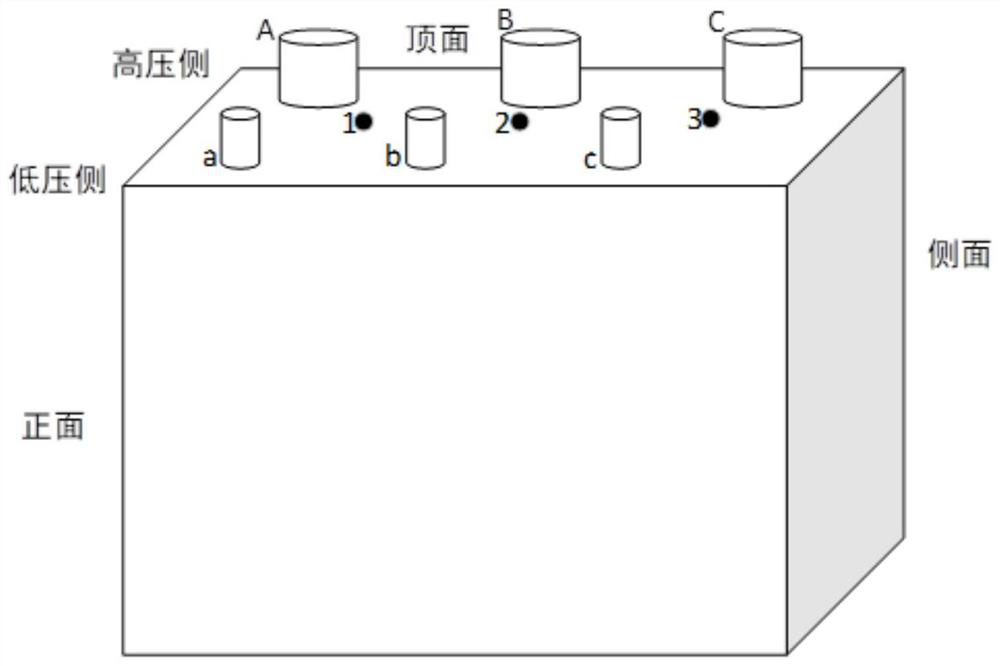

[0059] The vibration on the surface of the transformer mainly comes from the vibration of the iron core and winding. When the power transformer is running stably, the magnetostriction of the silicon steel sheet causes the iron core to vibrate, and the electromotive force generated between the windings, the wire cakes, and the wire turns when the current passes through the windings causes the windings to vibrate. When the transformer is running, its loading voltage, load current and oil temperature will affect the vibration signal on the surface of the transformer oil tank, which will bring errors to the acquisition of vibration signals and affect the results of fault diagnosis. Therefore, it is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com