Method for calculating furnace top gas volume based on blast furnace working condition

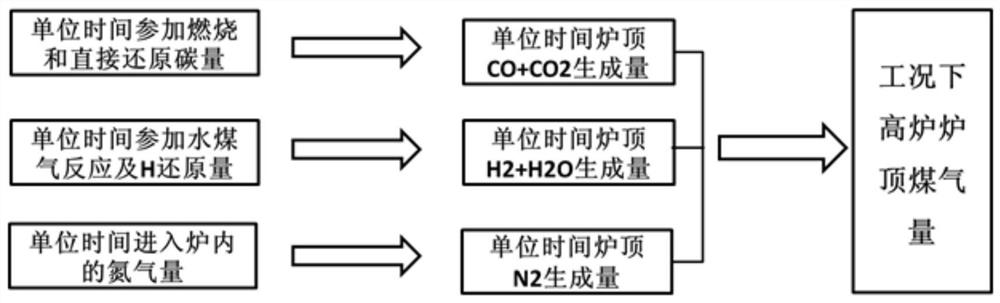

A calculation method and a furnace top gas technology, which are applied in the field of iron and steel metallurgy blast furnaces, can solve the problems that the key parameters of the blast furnace cannot be calculated to provide an accurate basis for the balance of the blast furnace gas, and the amount of the top gas cannot be accurately reflected, so as to achieve the effect of facilitating the balance of blast furnace gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

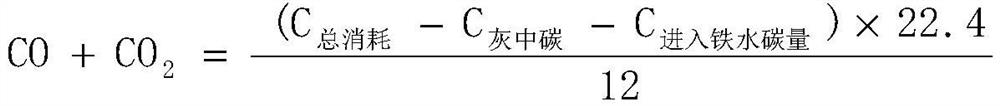

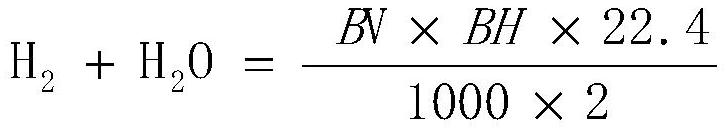

Method used

Image

Examples

Embodiment example 1

[0117] The calculation method used in the implementation case 1 is the calculation method of the present invention, calculates the furnace top gas volume (Q 炉顶煤气量 ), the specific results are shown in Table 3.

[0118] Table 3 Implementation Case 1 Results

[0119]

[0120] By comparing with the traditional calculation method, compared with the calculation result of the present invention, the calculation result of the top gas volume of the traditional measurement result is relatively small, and the deviation is about 10% under the coal injection load furnace condition.

Embodiment example 2

[0122] The above three working conditions are the conditions of three different production periods of the blast furnace, corresponding to the statistics of the blast furnace gas production under these working conditions, this implementation case calculates the period of time by counting the consumption of blast furnace gas users.

[0123] Table 4 The actual production results of the implementation case

[0124]

[0125] The results of the benchmark embodiment to the implementation case 2 are compared, and the comparison results are shown in Table 5.

[0126] Can find out by result comparison, the method for traditional blast furnace top gas measurement and calculation can't accurately calculate the top gas volume under various working conditions of blast furnace, and the top gas volume under the working conditions measured and calculated by the present invention and blast furnace various working conditions The variation trend of the statistical furnace top gas volume under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com