Method and device for capturing sintering machine tail section picture

A section and picture technology, applied in the field of image recognition, can solve the problem of loss of sintering information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

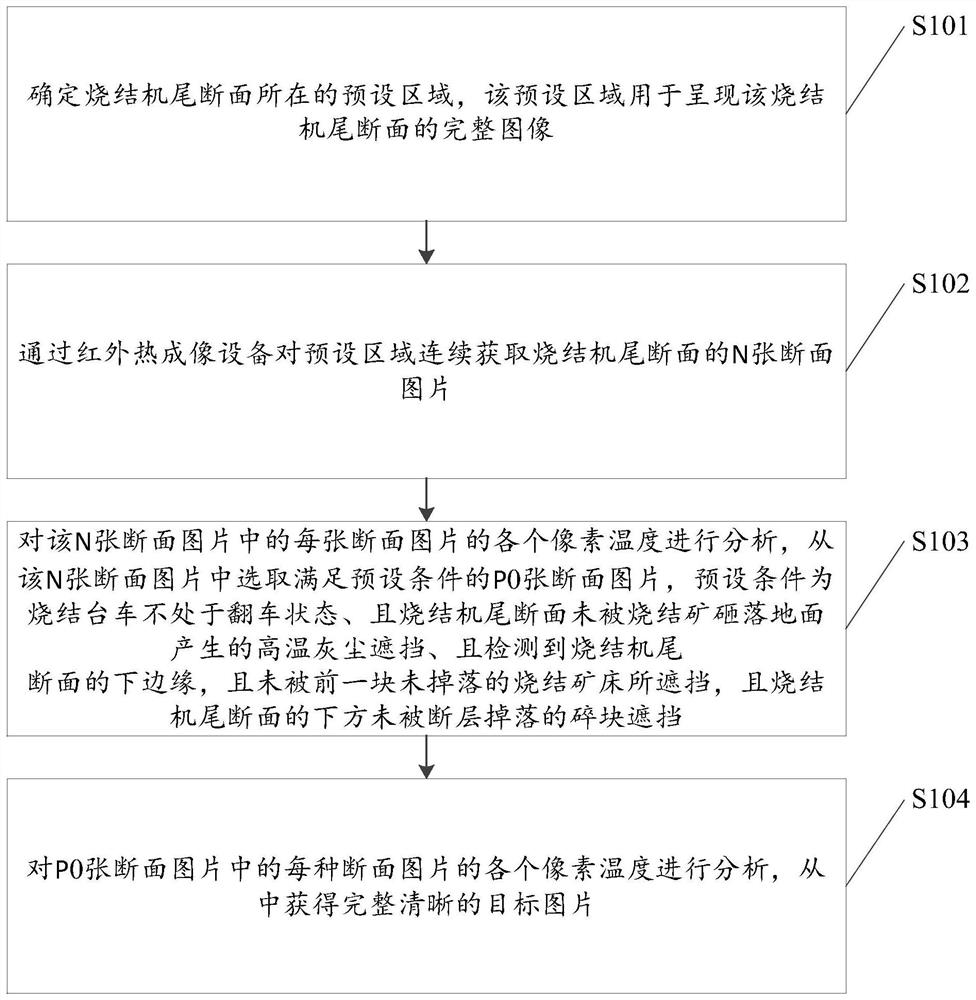

[0062] Embodiment 1 of the present invention provides a method for capturing a section picture of a sintering machine tail, such as figure 1 shown, including:

[0063] S101. Determine a preset area where a sintering machine tail section is located, and the preset area is used to present a complete image of the sintering machine tail section.

[0064] S102. Continuously acquire N cross-sectional pictures of the tail section of the sintering machine in a preset area by using an infrared thermal imaging device.

[0065] S103, analyze the temperature of each pixel in each of the N cross-sectional pictures, select P0 cross-sectional pictures from the N cross-sectional pictures that meet the preset condition, and the preset condition is that the sintering trolley is not in an overturned state , and the section of the tail of the sintering machine is not blocked by the high-temperature dust generated by the sinter falling on the ground, and the lower edge of the section of the tail ...

Embodiment 2

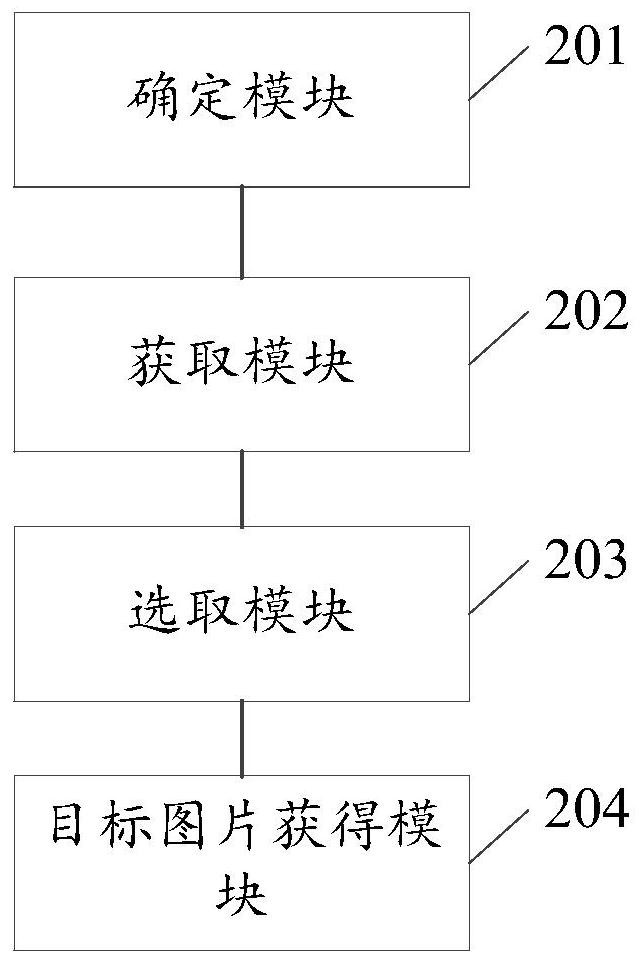

[0122] Based on the same inventive concept, Embodiment 2 of the present invention also provides a device for capturing pictures of sintering machine tail sections, such as figure 2 shown, including:

[0123] A determining module 201, configured to determine a preset area where the tail section of the sintering machine is located, and the preset area is used to present a complete image of the tail section of the sintering machine;

[0124] An acquisition module 202, configured to continuously acquire N cross-sectional pictures of the tail section of the sintering machine in the preset area through an infrared thermal imaging device;

[0125] The selection module 203 is configured to analyze the temperature of each pixel in each of the N cross-sectional pictures, and select P0 cross-sectional pictures from the N cross-sectional pictures that meet the preset conditions, and the preset conditions The sintering trolley is not in the overturned state, and the tail section of the s...

Embodiment 3

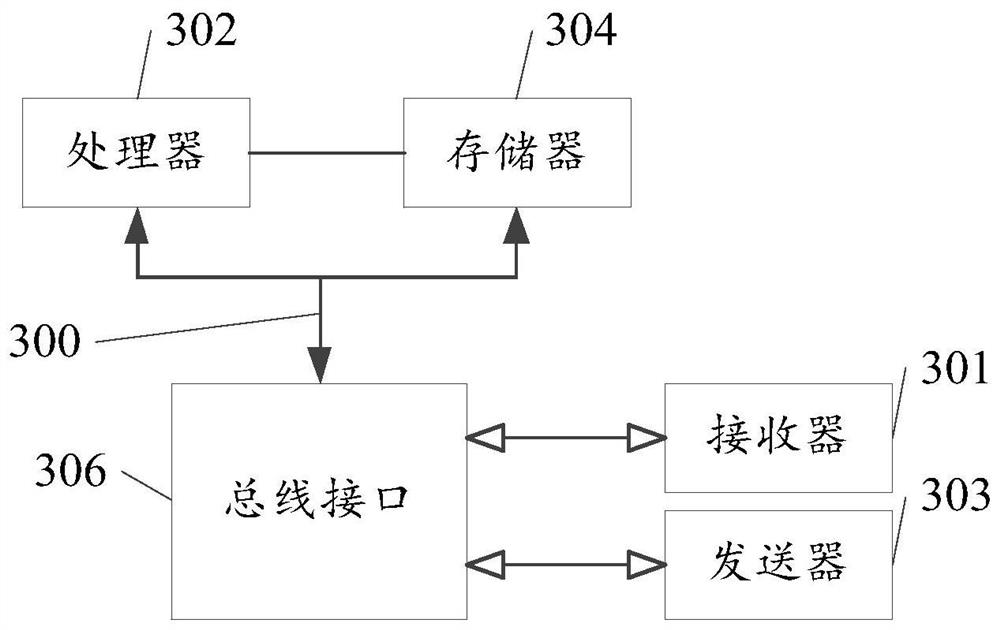

[0146] Based on the same inventive concept, Embodiment 3 of the present invention provides an electronic device, such as image 3 As shown, it includes a memory 304, a processor 302, and a computer program stored on the memory 304 and operable on the processor 302. When the processor 302 executes the program, the above steps of the method for capturing the sintering machine tail section picture are realized. .

[0147] Among them, in image 3 In, bus architecture (represented by bus 300), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits linked together. The bus 300 may also link together various other circuits, such as peripherals, voltage regulators, and power management circuits, etc., which are well known in the art and thus will not be further described herein. The bus interface 306 provides an interface between the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com