High-pressure water cooling resistor

A water-cooled resistor, high-voltage technology, applied in resistors, resistor parts, resistor cooling/heating/ventilation devices, etc., can solve the problems of low cooling water level, prone to electric shock accidents, damage and aging of sealing rings, etc. The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

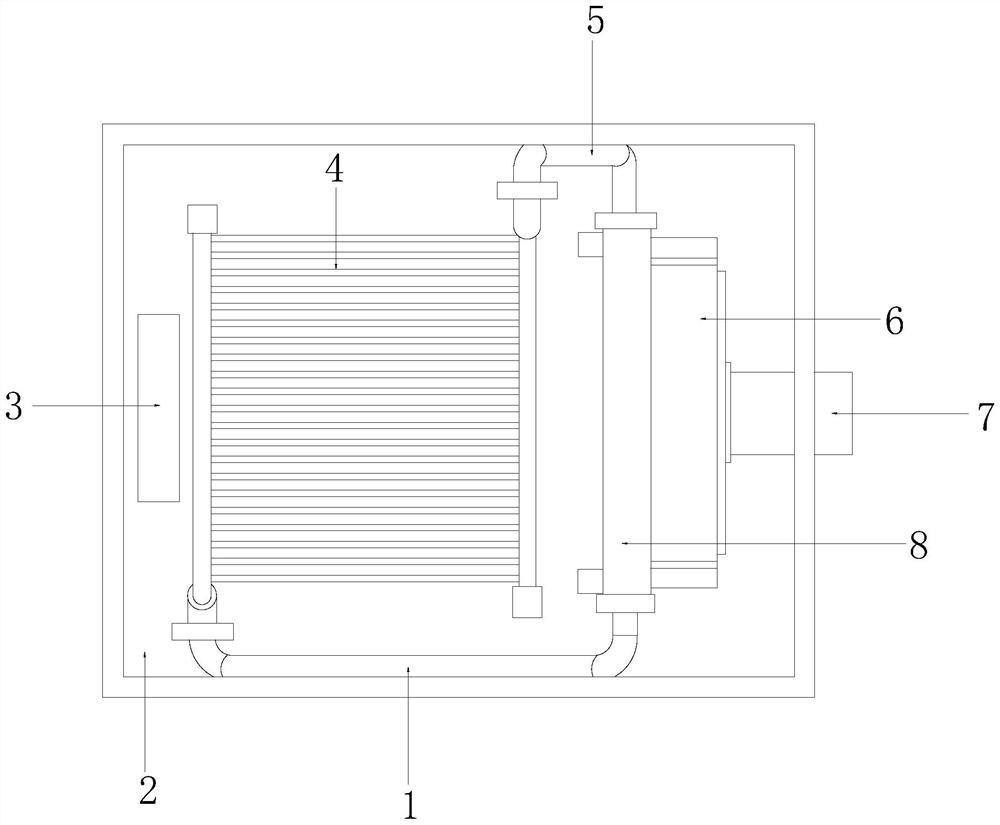

[0030] See figure 1 The present invention provides a technical solution: a high-pressure water-free resistor, which includes a first conduit 1, a casing 2, a wiring electrode plate 3, a water-cooled resistor 4, a second conduit 5, a heat sink 6, an inward, and an in-force. The processing apparatus 8 is turned on with the water-cooled resistor 4 phase and the other end is turned on with the processing apparatus 8, and the water-cooled resistor 4 is fixed inside the casing 2, the water-cooled resistor 4 and a wiring electrode plate. 3 is connected by a wire, the water-cooled resistor 4 is turned on from one end of the first conduit 1 and the second conduit 5, and the second conduit 5 is connected to the first conduit 1, the processing device 8 and The heat sink 6 is connected, and the heat sink 6 is turned on with the inlet and exit 7.

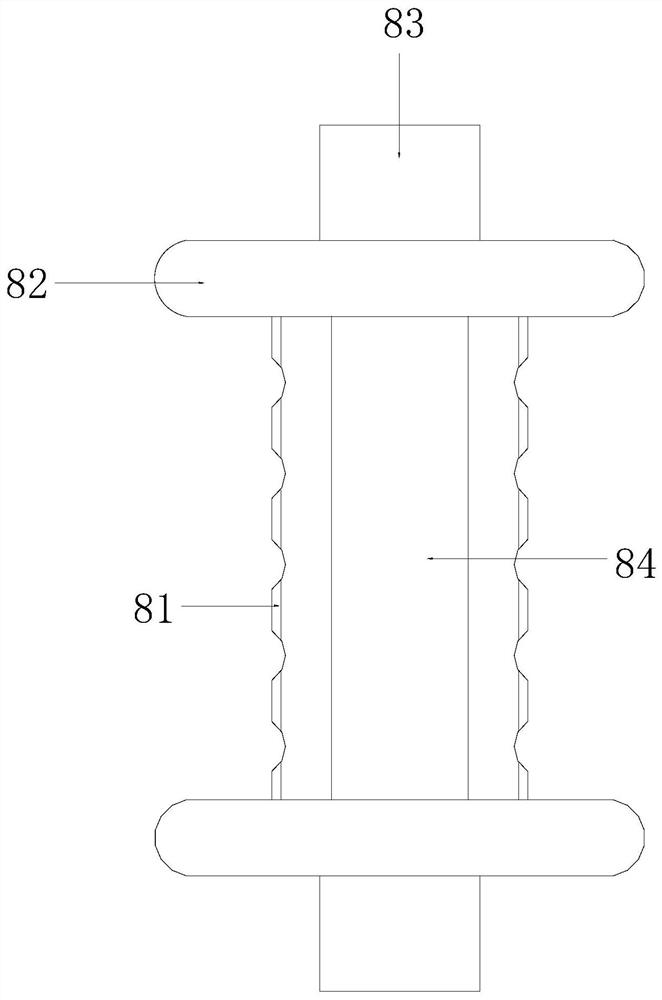

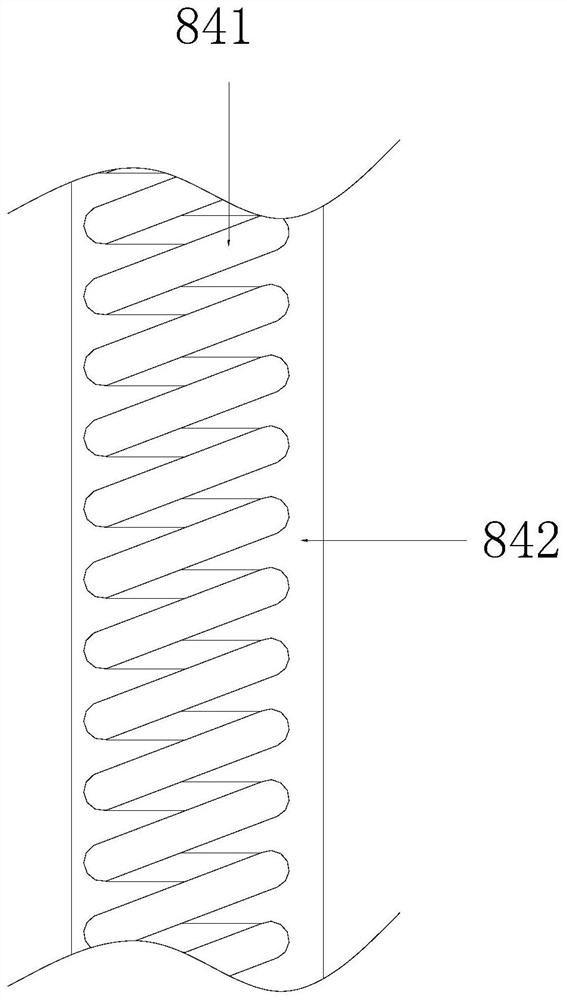

[0031] See figure 2 The processing apparatus 8 includes a conductive assembly 81, a seal 82, an interface 83, a cyclone 84, and the conductive asse...

Embodiment 2

[0040] See figure 1 The present invention provides a technical solution: a high-pressure water-free resistor, which includes a first conduit 1, a casing 2, a wiring electrode plate 3, a water-cooled resistor 4, a second conduit 5, a heat sink 6, an inward, and an in-force. The processing apparatus 8 is turned on with the water-cooled resistor 4 phase and the other end is turned on with the processing apparatus 8, and the water-cooled resistor 4 is fixed inside the casing 2, the water-cooled resistor 4 and a wiring electrode plate. 3 is connected by a wire, the water-cooled resistor 4 is turned on from one end of the first conduit 1 and the second conduit 5, and the second conduit 5 is connected to the first conduit 1, the processing device 8 and The heat sink 6 is connected, and the heat sink 6 is turned on with the inlet and exit 7.

[0041] See figure 2 The processing apparatus 8 includes a conductive assembly 81, a seal 82, an interface 83, a cyclone 84, and the conductive asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com