Secondary ink box for ink-jet printer

An inkjet printer, secondary ink cartridge technology, applied in printing and other directions, can solve the problems of unstable ink circulation pressure, easy to be polluted or generated bubbles, easy to receive pollution, etc., to reduce the possibility of pollution and bubble generation, Guarantee printing stability and avoid the effect of ink precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

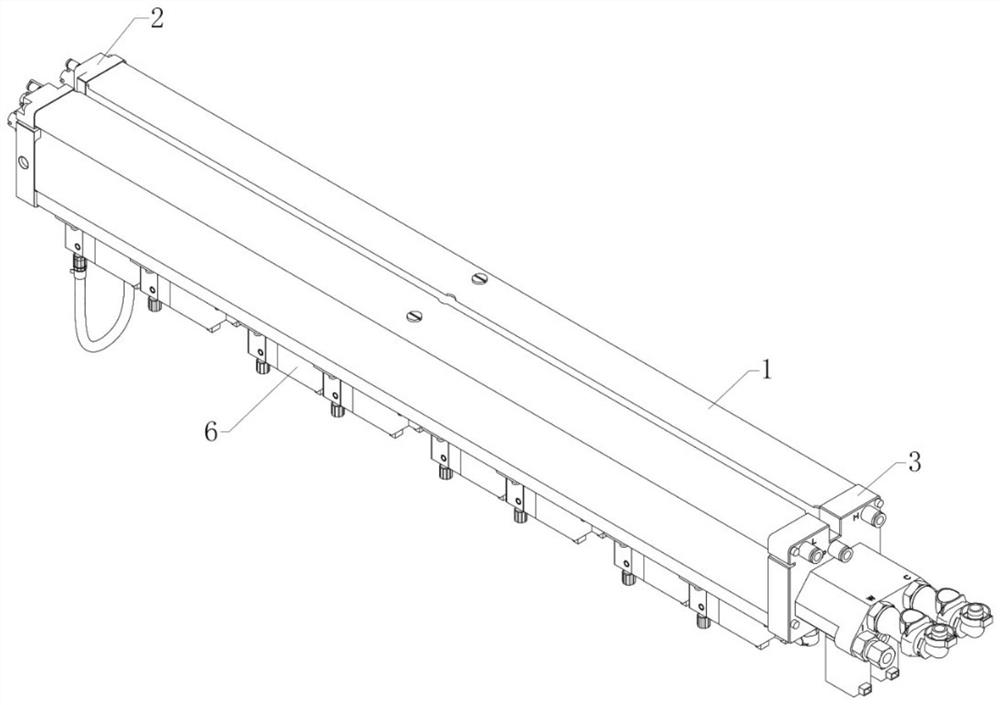

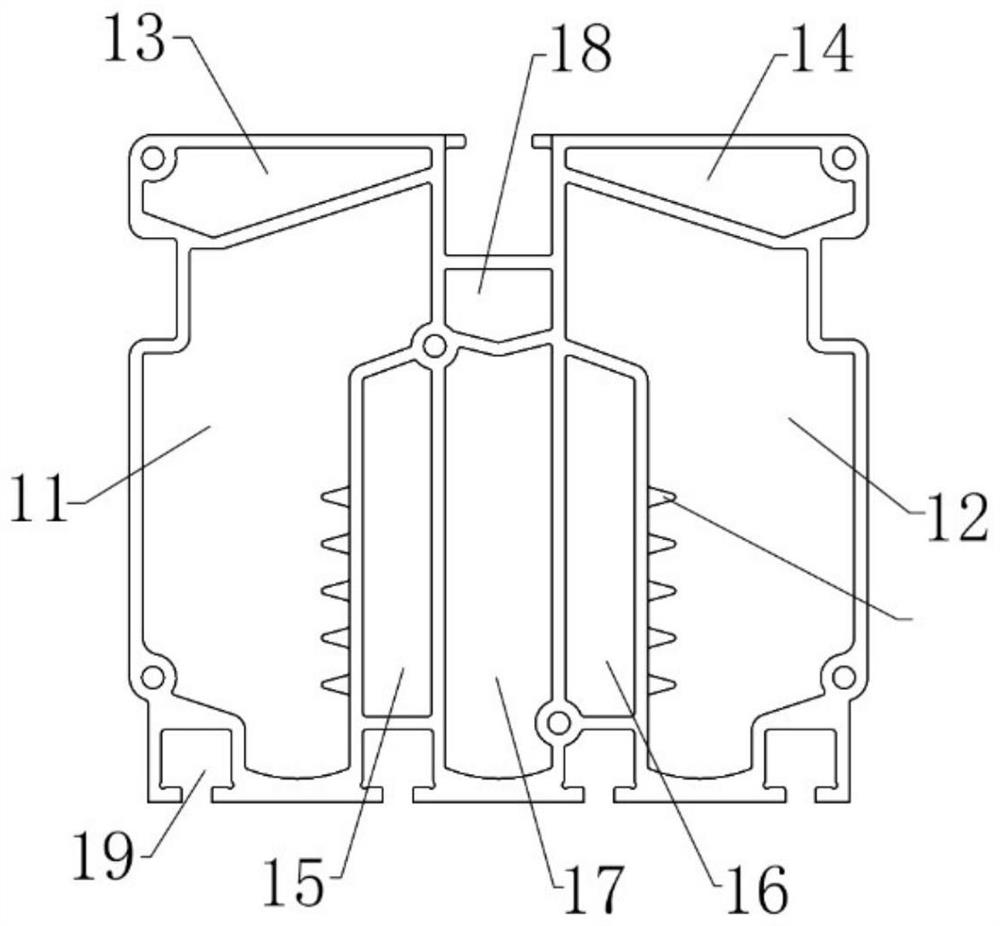

[0061] refer to figure 1 and figure 2 As shown, a secondary ink cartridge for an inkjet printer is improved in that it includes an ink cartridge body 1, a rear end cover 2 and a front end cover 3 that are respectively sealed and closed with the ink cartridge body 1, and the ink cartridge body 1 There are ink supply chambers 11 and return ink chambers 12 respectively located on the left and right sides thereof, the bottoms of the ink supply chamber 11 and the return ink chamber 12 are respectively provided with several ink holes, and the ink supply chamber 11 and the ink return chamber 12 are respectively provided with ink holes. The liquid level sensors used to detect the amount of ink in the ink chamber are respectively provided in the described backflow ink chamber 12, the top of the described ink supply chamber 11 is provided with a negative pressure chamber I13 communicating with it, and the top of the described backflow ink chamber 12 is provided with There is a negativ...

Embodiment 2

[0066] On the basis of Embodiment 1, the ink return chamber 12 communicates with the main ink tank of the printer, the ink return chamber 12 communicates with one end of the degasser, and the other end of the degasser communicates with the supply The ink chambers 11 are connected.

[0067] In this embodiment, the ink in the main ink tank is continuously pumped into the return ink chamber 12 by the pump, and the ink pumped into the return ink chamber 12 by the main ink tank is inevitably mixed with air bubbles, and the ink mixed with air bubbles enters the printing ink chamber. The nozzle is prone to empty spraying during printing, which affects the printing quality. Therefore, another circulation path is set between the return ink chamber 12 and the ink supply chamber 11. This circulation path is used to remove the ink entering the ink supply chamber 11. The air bubbles in the return ink chamber 12 flow into the degassing device under the action of the pump, and enter the ink ...

Embodiment 3

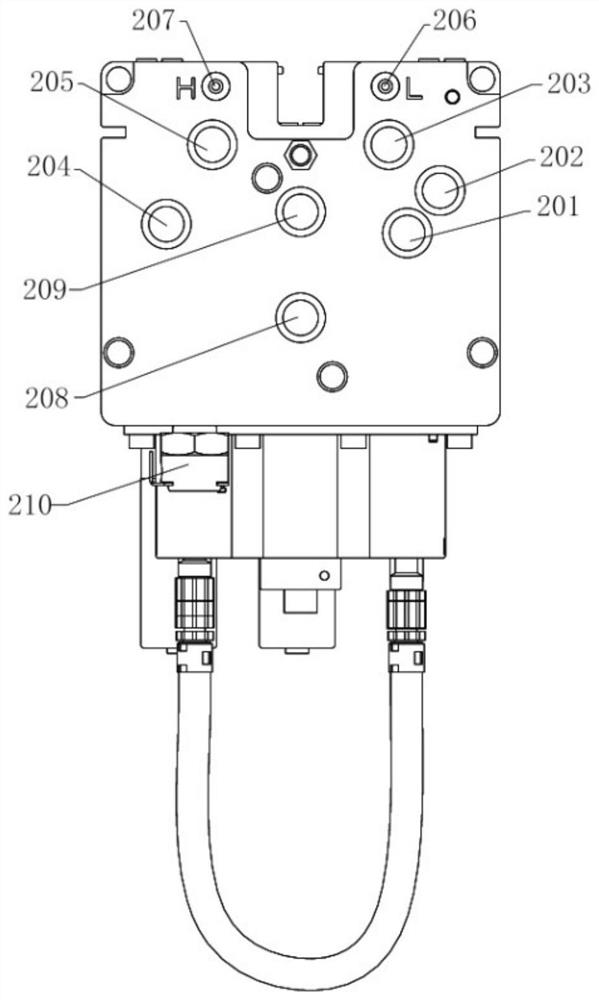

[0069] On the basis of embodiment 2, with reference to Figure 3 to Figure 8 As shown, the liquid level sensors in the return ink chamber 12 include a low liquid level sensor II204 and a high liquid level sensor II205.

[0070] Further, the low liquid level sensor II204 and the high liquid level sensor II205 are installed on the rear end cover 2 and placed in the ink return chamber 12 .

[0071] Further, the ink return chamber 12 is provided with an ink pipe II5, and the ink pipe II5 is installed between the front end cover 3 and the rear end cover 2, perpendicular to the front end cover 3 and lower than the Low level sensor II204, refer to Figure 11 As shown, the bottom of the ink tube II5 is provided with several through holes II.

[0072] Further, an ink inlet joint I301 is installed on the outside of the front end cover 3, and an ink inlet hole 311 is arranged on the inside of the front end cover 3, and the ink inlet hole 311 communicates with the ink inlet connector I3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com