Four-quadrant low-noise electric reactor and manufacturing method thereof

A low-noise, reactor technology, used in the manufacture of inductors/transformers/magnets, transformers/inductor cores, circuits, etc., can solve the problems of high cost and high noise of the reactor, and achieve easy heat dissipation and uniform air gap distribution. , the effect of affordable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

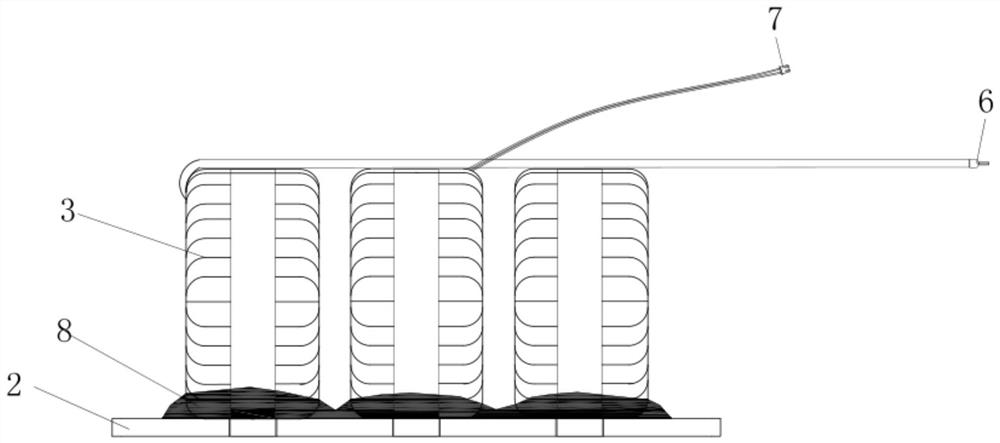

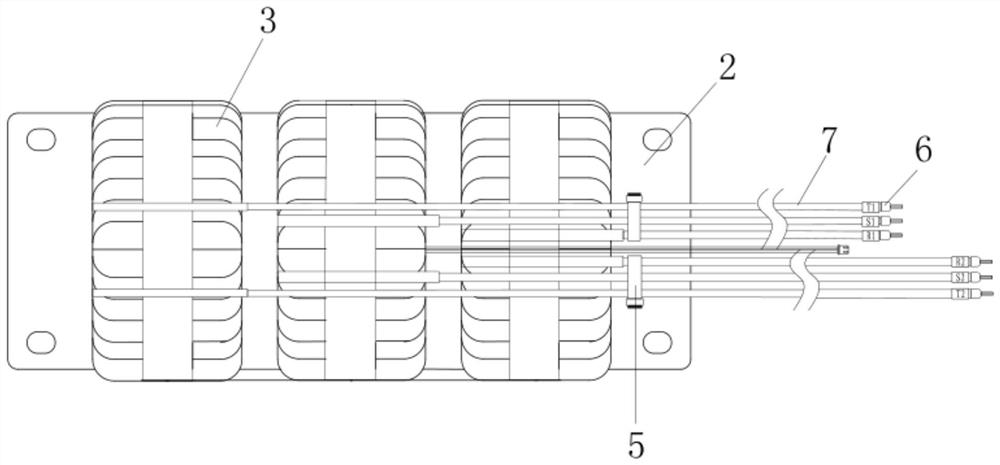

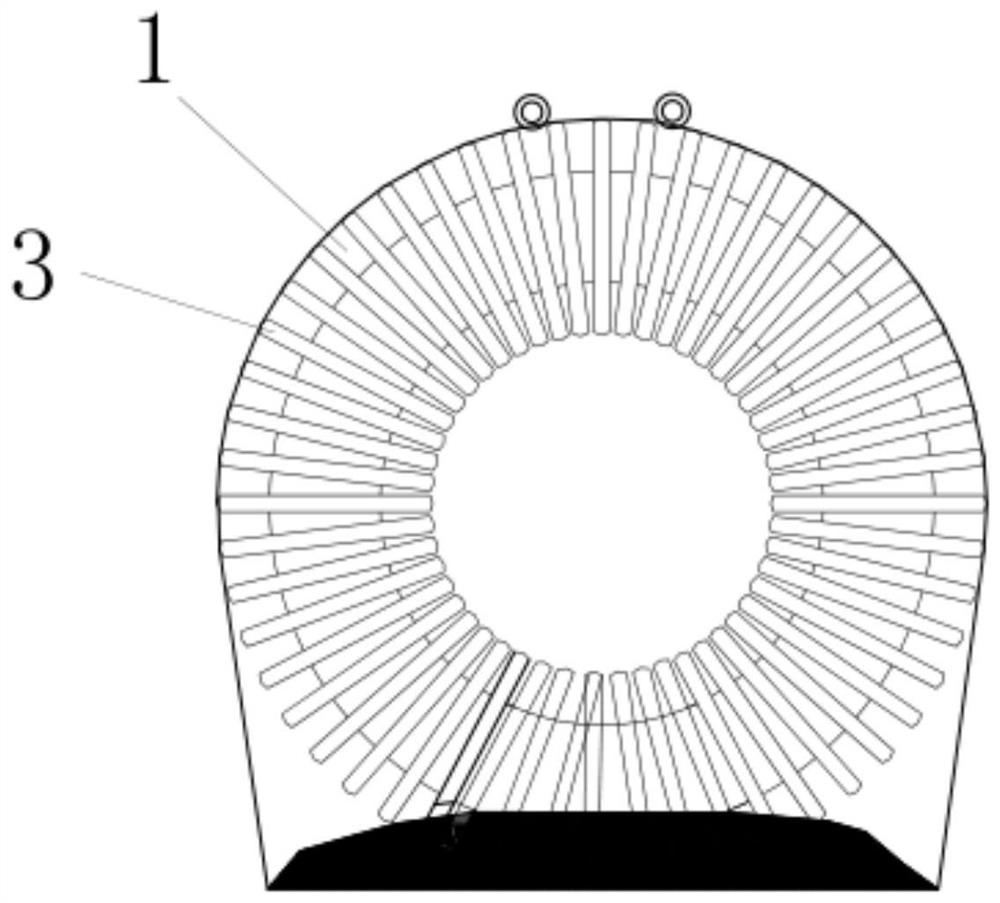

[0029] see Figure 1-5 , a four-quadrant low-noise reactor, including a ferrosilicon core 1, epoxy board 2, enamelled aluminum wire 3, temperature sensor 4, nylon cable tie 5 and terminal 6.

[0030] There are three iron-silicon magnetic cores 1, and the iron-silicon magnetic cores 1 are bonded side by side on the epoxy board 2 through glue 8. The enamelled aluminum wire 3 is wound around the outer periphery of the iron-silicon magnetic core 1, and each iron The two ends of the enamelled aluminum wire 3 on the silicon core 1 are connected to the terminal 6 through a high-temperature silicone cable 7, and the iron-silicon core 1 in the middle is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com