Cleaning device for an optical sensor and sensor assembly

A technology of optical sensors and sensor components, applied in the direction of optical device exploration, optical components, cleaning methods and utensils, etc., can solve the problem that cleaning devices are not as good as manual cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

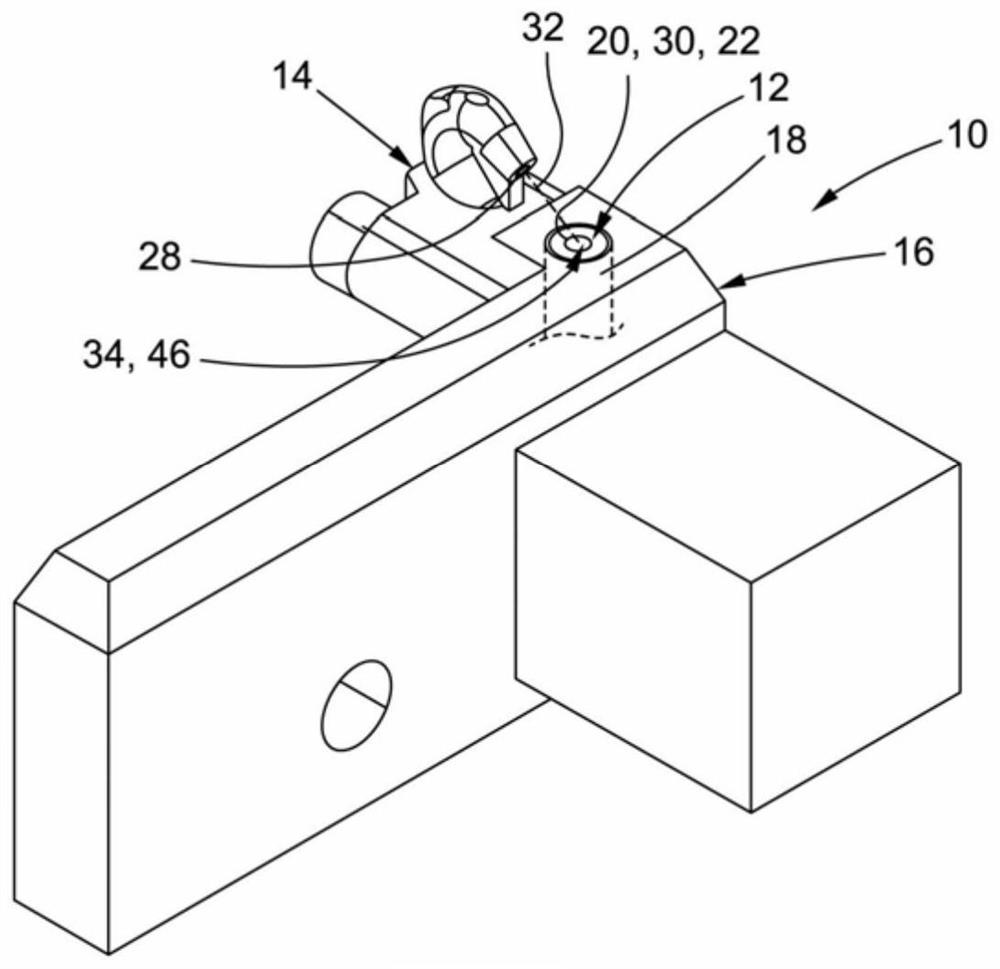

[0028] figure 1 A sensor assembly 10 is shown comprising an optical sensor 12 and a cleaning device 14 associated with the optical sensor 12 . Such sensor assemblies can be used in paper processing machines for detecting the presence of paper, for example in printing presses.

[0029] Both the optical sensor 12 and the cleaning device 14 are connected to a common support member 16 .

[0030] In the example shown, the optical sensor 12 includes an optical fiber 18 having an end face 20 . This end face 20 constitutes a sensing surface 22 of the optical sensor 12 .

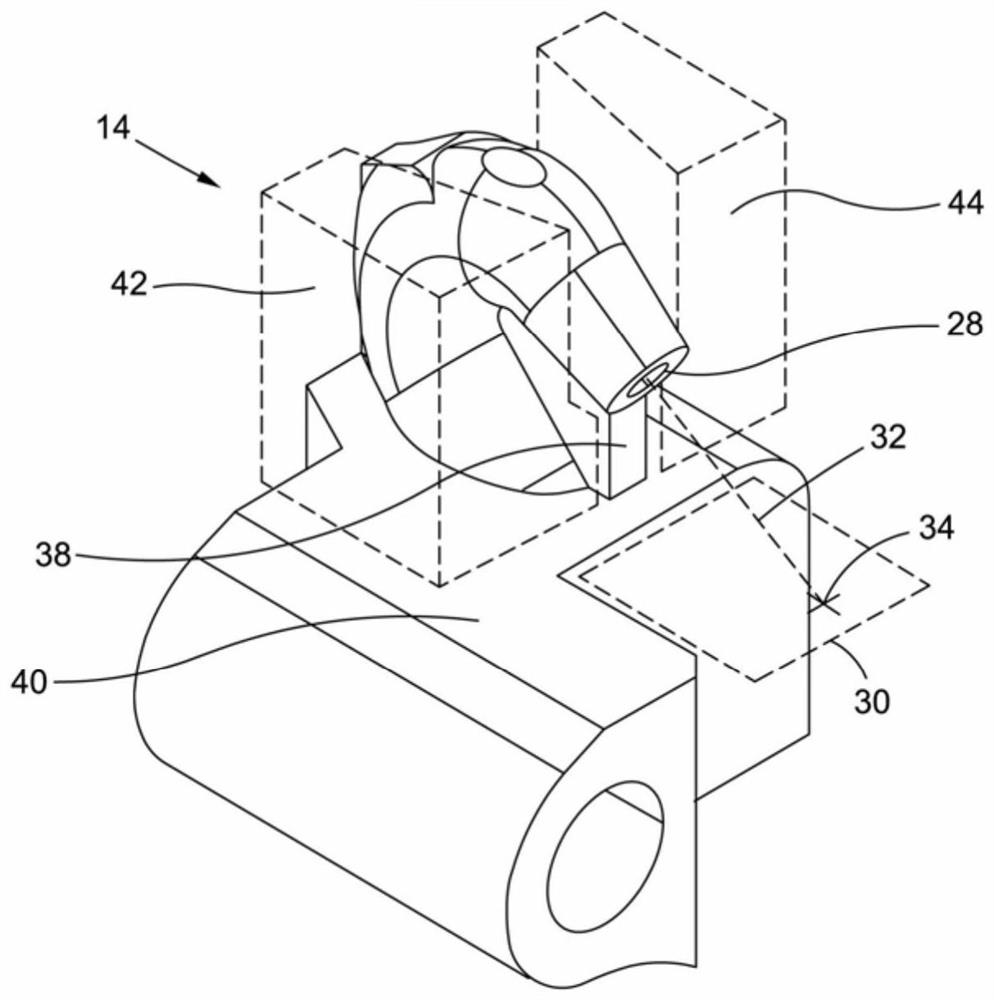

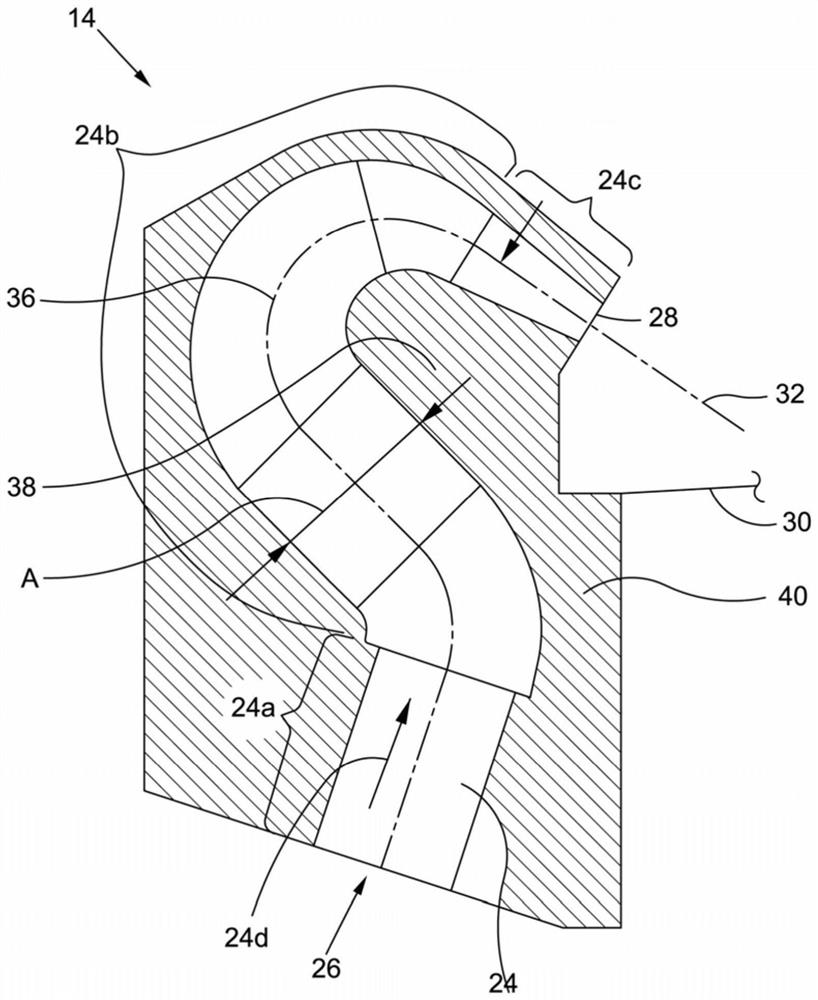

[0031] exist figure 2 and image 3 , the cleaning device 14 is shown in more detail. It includes a gas flow channel 24 having an inlet portion 24a, a middle portion 24b and an outlet portion 24c (see image 3 ).

[0032] The inlet portion 24a includes an inlet 26 to which air flow can be provided.

[0033] The outlet portion 24c includes an outlet 28 for discharging the airflow onto the target surface 30 of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap