Aerated concrete slab efficient casting molding equipment

A technology of pouring and forming of aerated concrete slabs, applied in auxiliary forming equipment, ceramic forming machines, climate sustainability, etc., can solve the problems of reducing pouring speed, prolonging vibration time, low production efficiency, etc., to reduce flow Time, improve pouring efficiency, shorten the effect of vibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

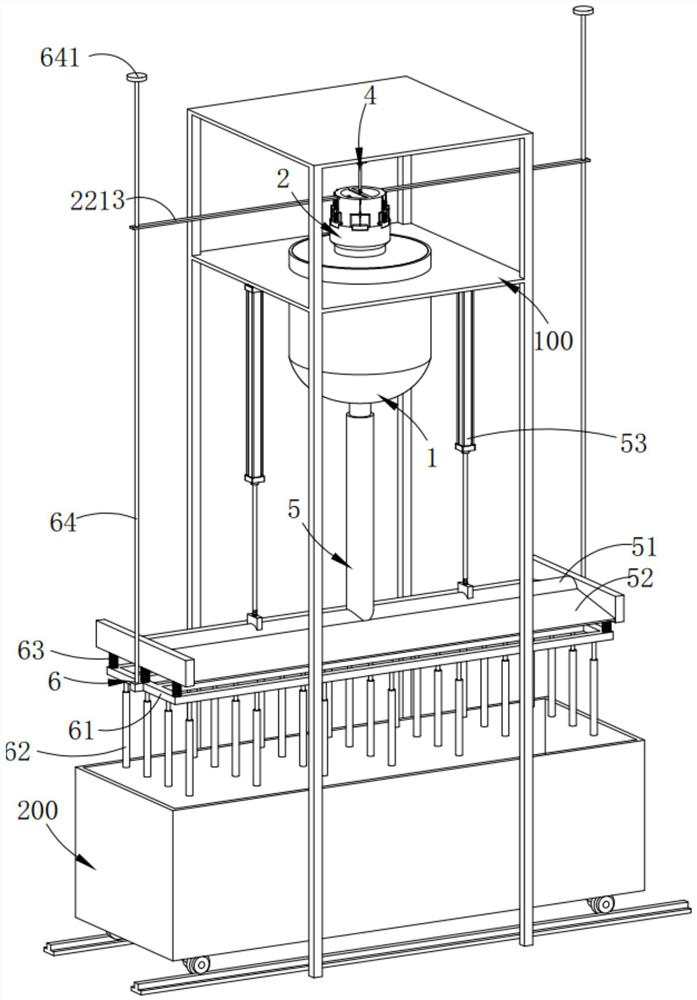

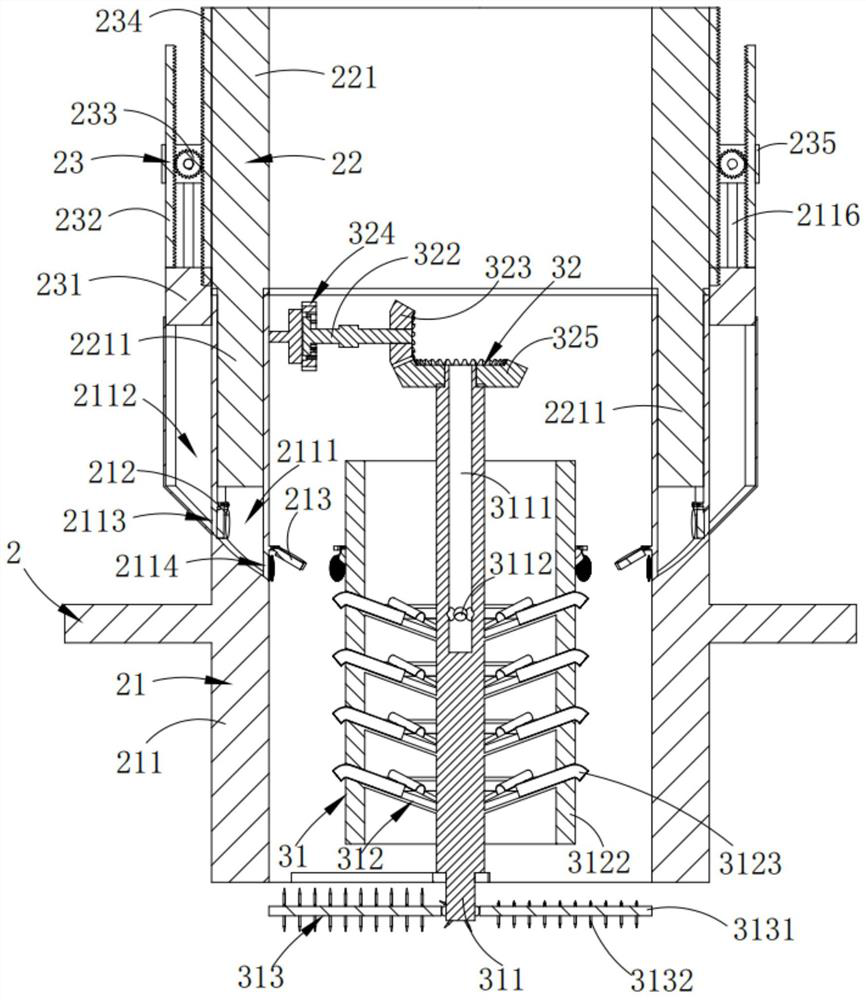

[0056] Such as Figure 1-3 As shown, an aerated concrete plate is highly efficiently cast, including a stirring bin 1 disposed on the device platform 100, further comprising: a powder control system 2 disposed over the stirring bin 1, provided in the powder The liquid control system 3 inside the control system 2 and the drive system 4 connected to the powder control system 2, the top end of the drive system 4 is connected to the top end of the device platform; wherein the drive system 4 can select a cylinder transmission, a gear Ratal transmission or other linear transmission mode; of course, cam transmissions can be selected;

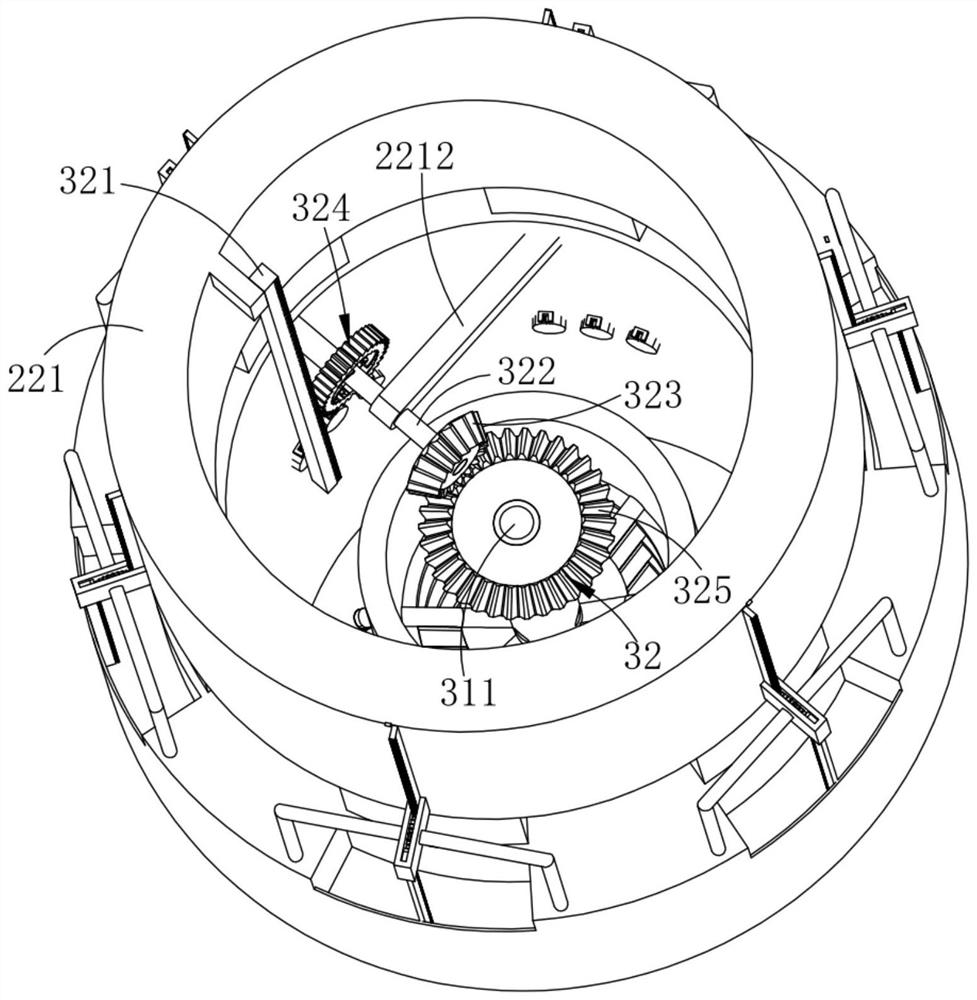

[0057] The powder control system 2 includes a powder adding unit 21 disposed at the 1 mouth of the agitation bin, which is slidably disposed above the powder adding unit 21, which is provided outside the injection transformer unit 22. Group add-in transformer unit 23;

[0058] The liquid control system 3 includes a fluid unit 31 provided in the powder addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com