Recyclable core mold for forming composite part with complex structure

A composite material and mandrel technology, which is applied in the field of carbon fiber composite material manufacturing, can solve problems such as the difficulty of removing the inner mandrel, and achieve the effects of improving manufacturing precision, reducing mold cost, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] The present invention will be further described in detail below in conjunction with accompanying drawings and examples.

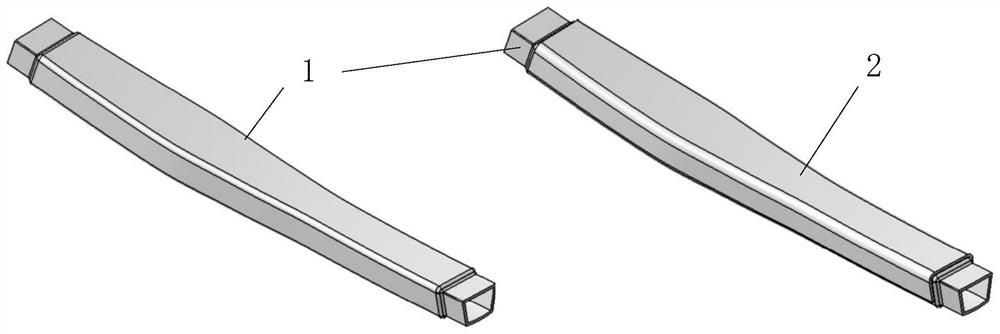

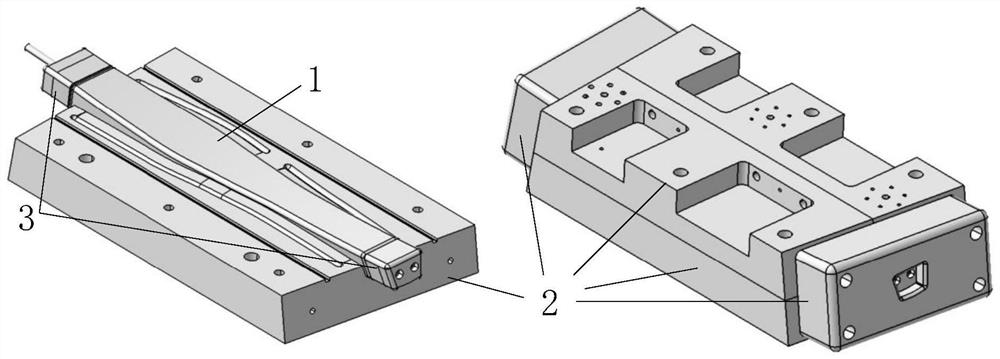

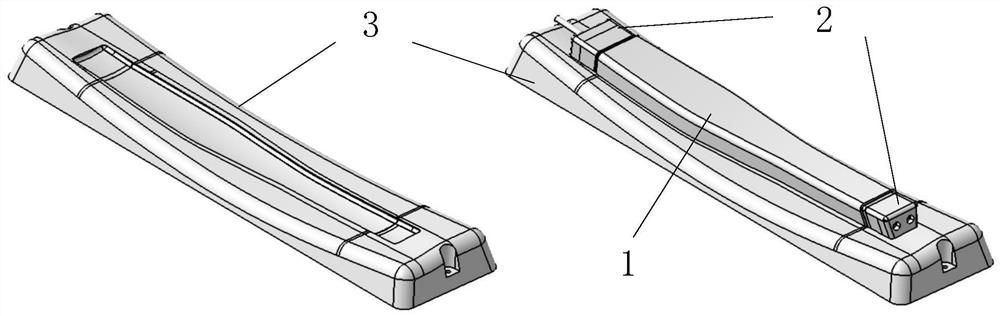

[0039] A kind of reusable recyclable mandrel technology for molding carbon fiber composite parts of the present invention comprises: figure 2 The recyclable mandrel 1 is made of thermoplastic composite material and is used for laying and curing of thermosetting composite material prepreg; figure 2 The metal manufacturing mold 2 in, is made up of many parts, is used for carrying out the preparation of recyclable mandrel itself and the reshaping of recyclable mandrel; figure 2 The metal terminal 3 in the middle is installed at both ends of the recyclable mandrel, and is used to seal the recyclable mandrel, so that the interior of the recyclable mandrel can be filled with air pressure; image 3 The part forming base 3 in the above is used to fix the recyclable mandrel and the ends on both sides when the prepreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com