A pipeline inspection robot with variable track and its control method

An inspection robot and robot technology, applied in the field of robotics, can solve problems such as insufficient contact between the track surface and the pipe wall, and achieve the effects of reducing energy consumption, improving work efficiency, and reducing track wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

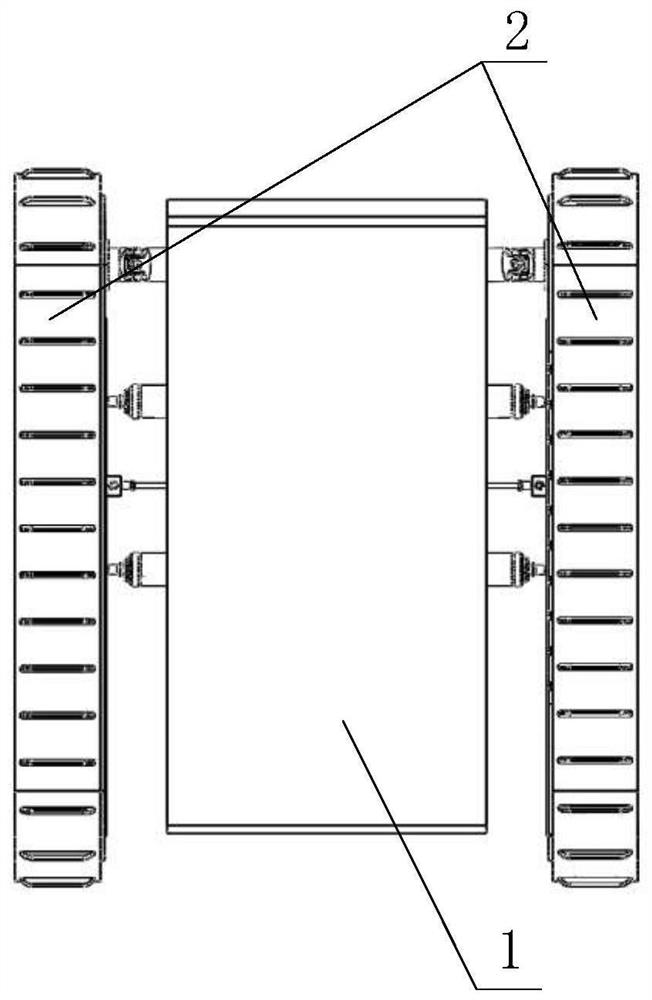

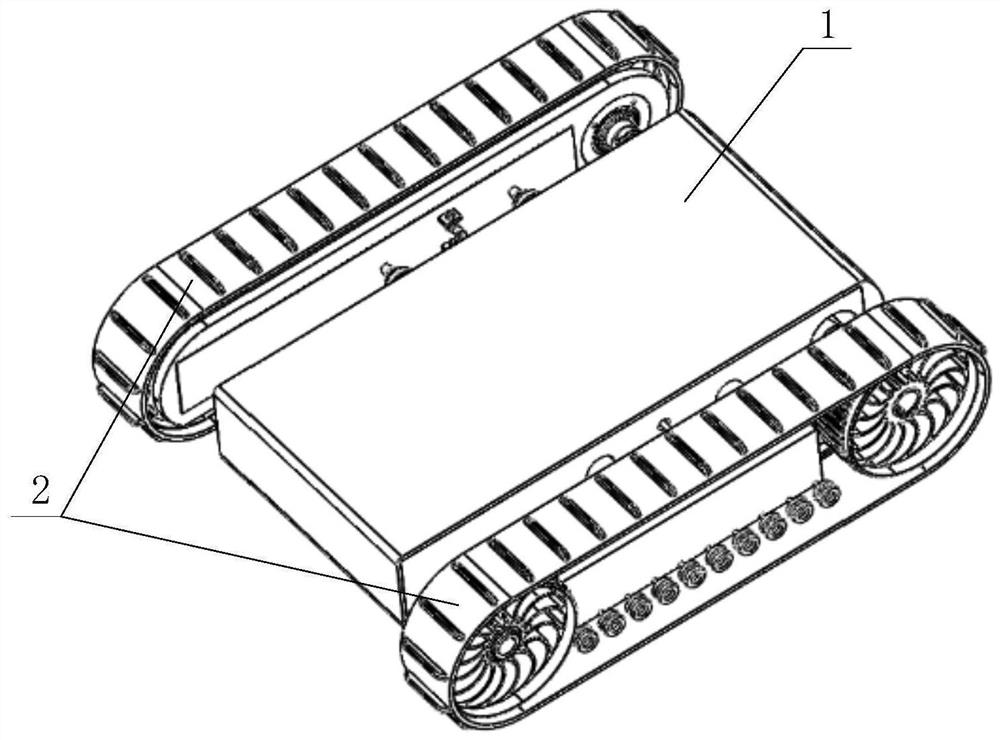

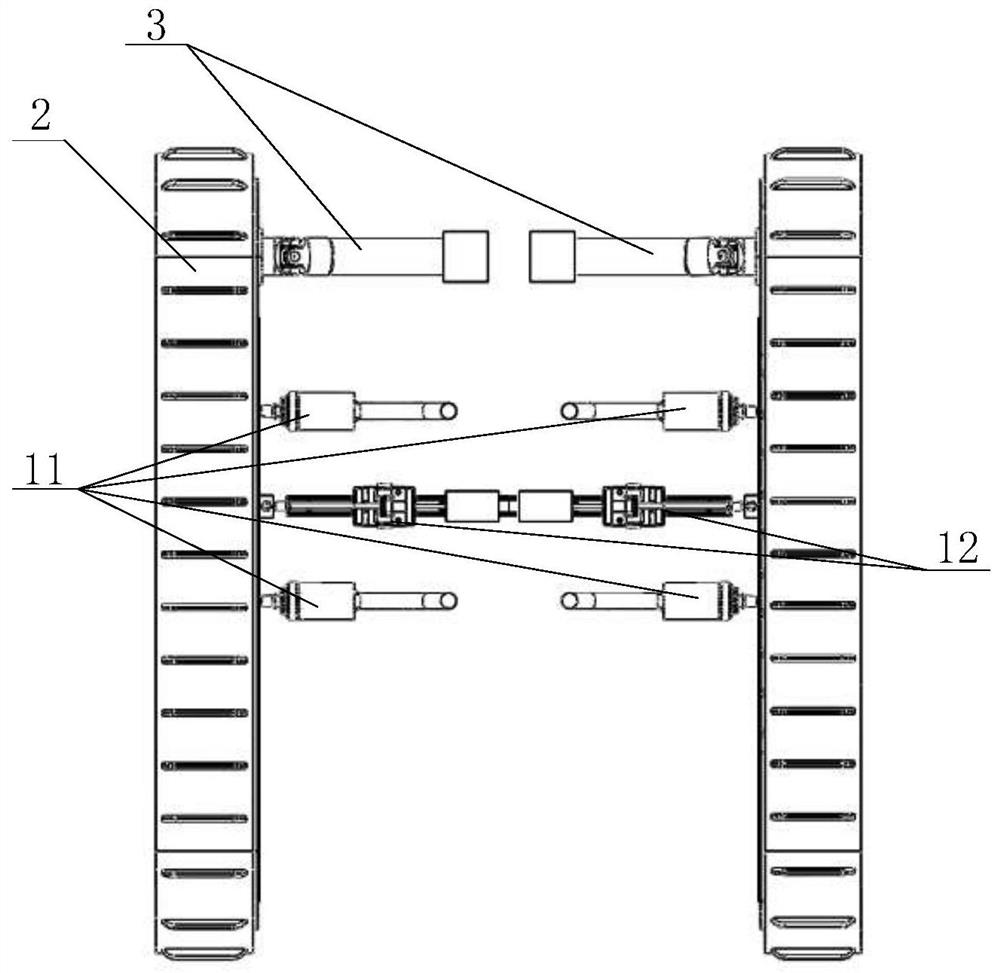

[0046] Such as figure 1 and figure 2 As shown, a pipeline inspection robot mechanism with variable crawlers includes a robot main body 1, crawler belt assemblies 2 on the left and right sides, and a traveling drive mechanism 3; 11, and a track angle adjustment mechanism 12 is respectively connected between the main body of the robot and the track assemblies on the left and right sides.

[0047] There are four groups of track fixing frames, which are symmetrically installed inside the main body of the robot, front and rear, and left and right. The symmetrical plane installed front and back is the plane where the four-bar linkage mechanism is located, and the installation height is the height of the transverse central axis 24 of the fixed side plate of the track. It plays a restraining role in the adjustment of the inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com