Dry quenching coke cooling and humidifying system

A coke and coke CDQ technology, applied in the field of coke CDQ, can solve the problems of harsh production environment, difficult separation of water and coke, etc., and achieve the effect of high application value, good application prospect, simple process and system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

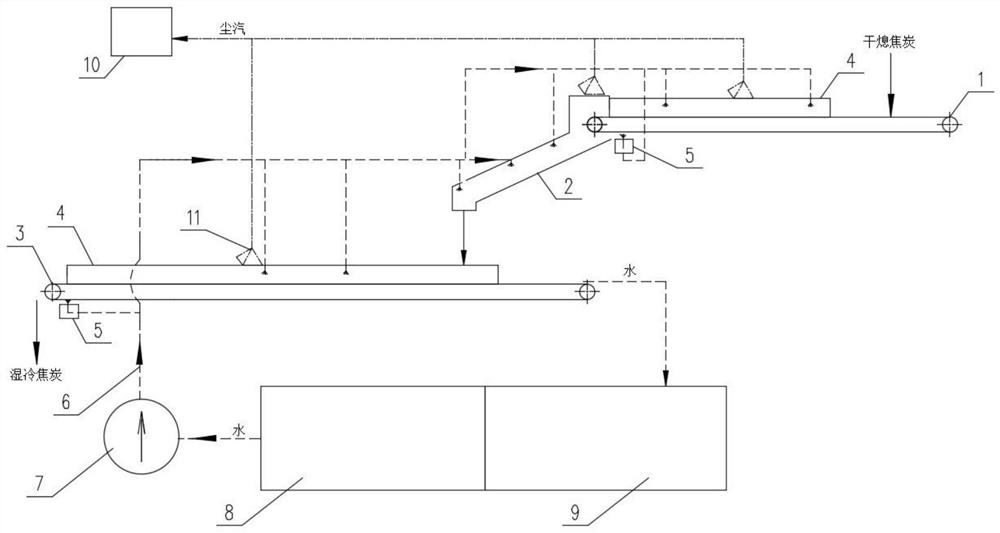

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] like figure 1 As shown, a CDQ coke cooling and humidification system of the present invention includes a belt conveyor one 1, a humidification chute 2, a belt conveyor two 3 and a coke water adding device; the belt conveyor one 1 The tail is the dry quenching coke receiving end, the head of the belt conveyor one 1 is connected to the tail of the belt conveyor two 3 through the humidification chute 2, and the head of the belt conveyor two 3 is the output end of the wet-cooled coke; the coke The water adding device includes a water pump 7, a water delivery pipeline 6 and a plurality of nozzles; one end of the water pump 7 is connected to the water source, and the other end is connected to the belt conveyor-1 along the CDQ coke delivery path through the water delivery pipeline 6, and the humidification chute 2, multiple nozzles above the belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com