Multi-performance detection device for building engineering construction

A technology for construction engineering and detection devices, which is applied to measurement devices, optical devices, buildings, etc., can solve the problems that the largest gap is not authentic, prone to large errors, and inaccurate detection results, so as to avoid using eyes The effect of fatigue, reduction in quantity, and reduction in labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

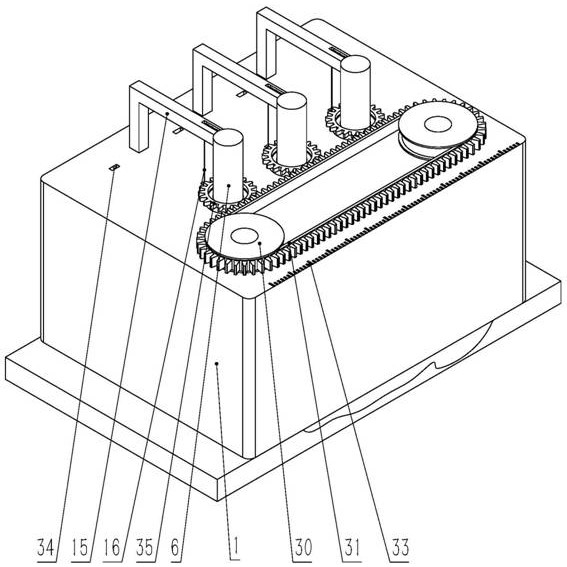

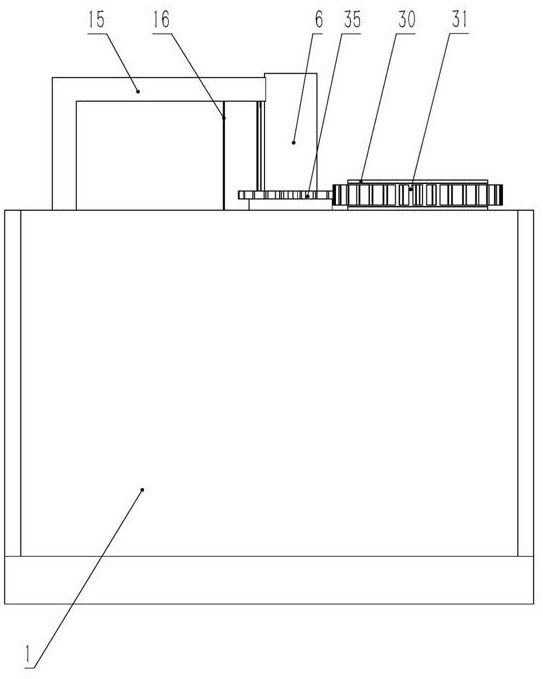

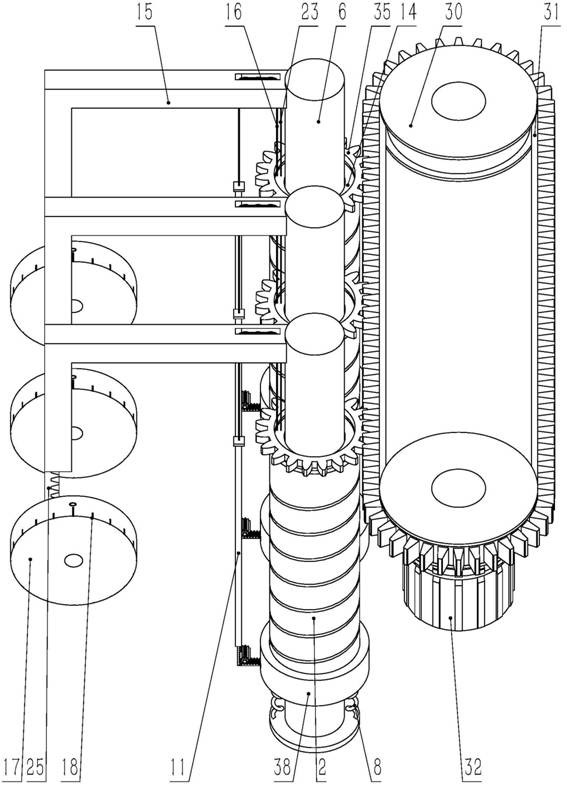

[0028] Embodiment 1, a multi-performance detection device for building engineering construction, including a detection ruler 1, a plurality of distance measuring mechanisms uniformly distributed along the front and rear directions on the detection ruler 1, and the distance measurement mechanism includes vertically arranged on the detection ruler 1 Screw 2, there is a cam push rod 4 that is slidingly matched with the spiral groove on the screw rod 2 on the detection ruler 1, the cam push rod 4 is placed on the left side of the screw rod 2 and placed under the thread groove on the screw rod 2, and the screw rod 2 is equipped with There is a through hole 5 coaxial with the screw 2, and there is a probe rod 6 coaxial with the screw 2 in the through hole 5, the lower end of the screw 2 is coaxially rotated and connected with a swivel 7, and the lower end of the probe 6 passes through the center of the swivel 7 From the hole to the bottom of the swivel 7, the lower end surface of the...

Embodiment 2

[0030] Embodiment 2, on the basis of Embodiment 1, the cantilever 15 is provided with a mounting groove placed directly above the connecting end of the ring 14 and the wire rope 16, the mounting groove runs through the cantilever 15 downwards, and the cantilever 15 is placed on the The delay mechanism in the installation groove, the delay mechanism includes the incomplete gear 19 that is rotatably connected on the cantilever 15, the axis of the incomplete gear 19 is arranged along the front and back direction, and the incomplete gear 19 is placed on the right side of the wire rope 16 in the cantilever 15, On the incomplete gear 19, there is a clip 20 in contact with the wire rope 16 in the cantilever 15. The clip 20 is placed at the bottom of the incomplete gear 19 and the clip 20 is inclined to the lower left. The vertical third rack 21 on the right side of the gear 19 and meshed with the incomplete gear 19 is vertically slidably connected between the third rack 21 and the can...

Embodiment 3

[0032] Embodiment 3. On the basis of Embodiment 1, the transmission mechanism includes a vertical fourth rack 25 connected to the left end of the cantilever 15 and placed below the cantilever 15. The detection ruler 1 is rotatably connected with The first transmission gear 26 meshed with the fourth rack 25, the first transmission gear 26 is coaxially connected with the second transmission gear 27, and the detection scale 1 is rotatably connected with the third transmission gear 28 meshed with the second transmission gear 27, The index circle diameter of the third transmission gear 28 is less than the index circle diameter of the second transmission gear 27, and the third transmission gear 28 is coaxially connected with the corresponding dial 17, because the depth of the concave part of the measured surface is generally Not too deep, the maximum distance that the rack moves down is the depth of the concave part. At this time, the rotation angle of the first transmission gear 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com