Flexible optical fiber cable

A fiber optic cable, flexible technology, applied in the field of optical fiber communication, can solve the problems of small braiding distance, difficulty in adjustment, and bending resistance of optical fiber, etc., and achieve the effect of improving tensile strength, bending resistance and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

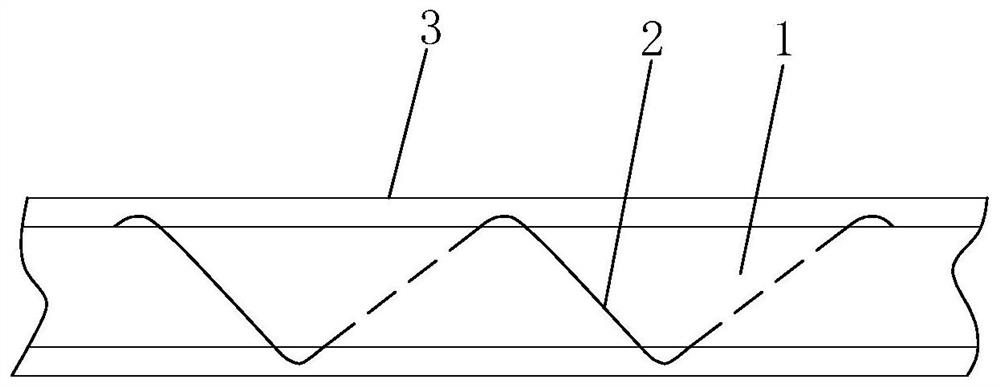

[0021] See figure 1 As shown, a flexible optical fiber cable of the present invention includes a core 1, an optical fiber layer located outside the core 1, and a protective layer 3 located outside the optical fiber layer. The optical fiber layer is formed by spirally winding a wire 2 outside the core 1. The wire 2 is an optical fiber, or the wire 2 includes an optical fiber. When the wire 2 is an optical fiber, the number of the optical fiber may be one or several.

[0022] In this embodiment, the ratio of the winding pitch of the wire 2 to the diameter of the wire core 1 is 4.5˜20:1. Specifically, the winding pitch of the wire 2 is 10-30 mm, and the diameter of the wire core 1 is 1.5-4 mm. The outer diameter of the protective layer 3 is 2-10mm. For example, when the diameter of the wire core 1 is 4 mm, the winding pitch of the wire 2 is about 18 mm; when the diameter of the wire core 1 is 2 mm, the winding pitch of the wire 2 is about 20 mm; When it is 1.5mm, the winding ...

Embodiment 2

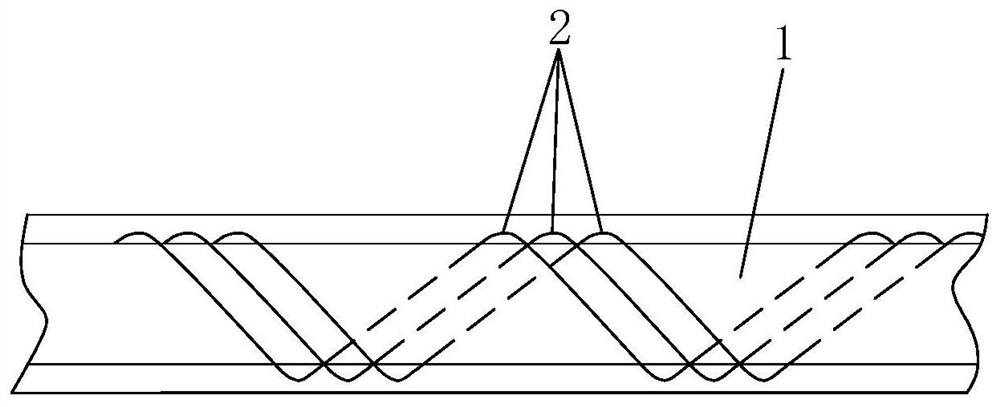

[0028] See figure 2 As shown, a flexible optical fiber cable of the present invention differs from the first embodiment above in that: the wires 2 are several, and the several wires 2 are wound side by side, so that it can solve the problem that one wire transmits multiple channels of different types. The problem of relatively inconvenient signals enables the present invention to connect multiple groups of different devices at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com