Power transmission line straight tower OPGW (Optical Fiber Composite Overhead Ground Wire) connection point deployment structure and method

A technology for linear towers and transmission lines, which is applied in the field of OPGW connection point deployment structure of transmission lines, can solve the problems of long construction operation time, large communication network range, long construction time, etc., and achieves flexible use, convenient communication channels, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

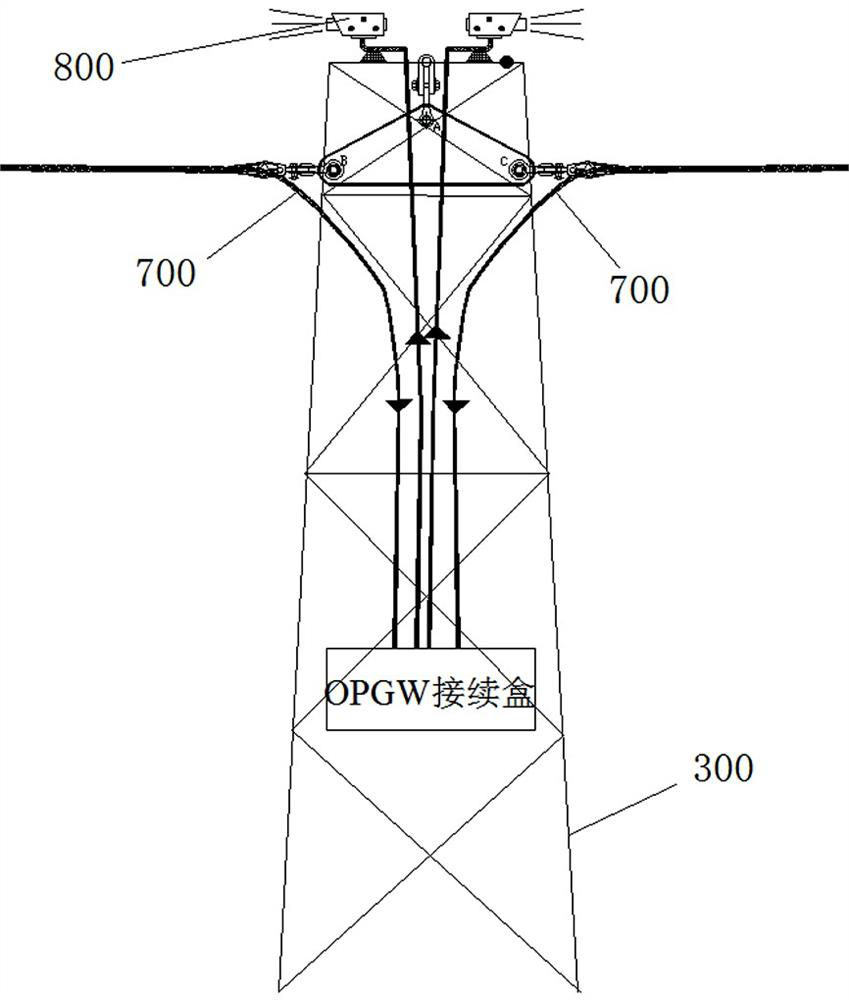

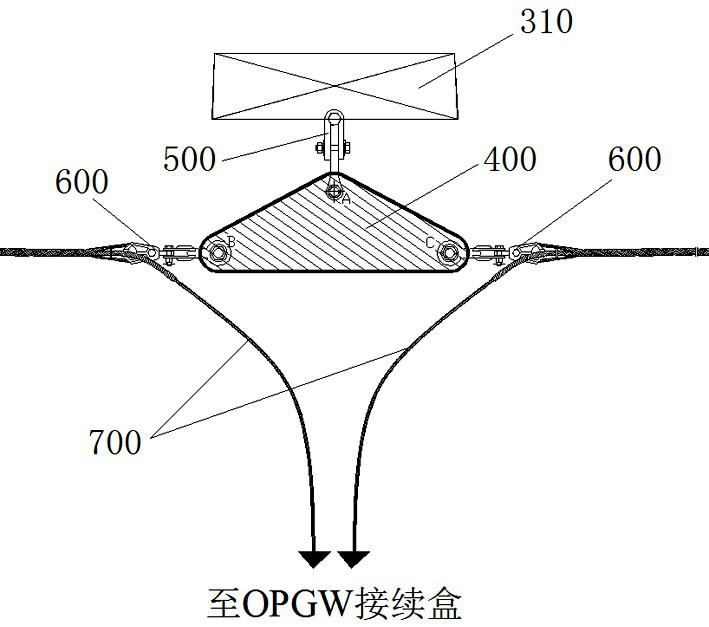

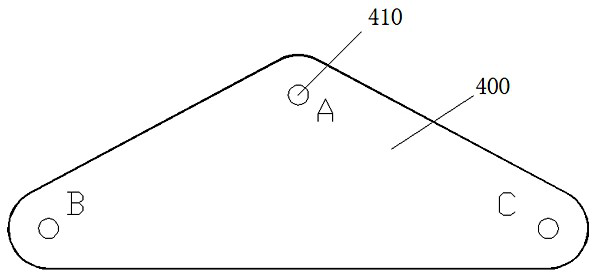

[0025] Such as Figure 1~5 As shown, a transmission line straight tower OPGW connection point deployment structure includes an OPGW connection box installed on the lower part of the straight tower 100 and a triangular connecting plate 400 installed on the upper part of the straight tower for hanging OPGW optical cables. The triangular connecting plate 400 It is in the shape of an isosceles triangle, the top corner of the triangular connecting plate 400 is hung on the cross arm of the straight pole tower through the optical cable hanging point fitting 500, and the OPGW optical cables on both sides are respectively hung on the triangular connecting plate 400 through the optical cable pre-hinged fitting 600. On the two bottom corners, the OPGW optical cables on both sides are led down to the lower part of the straight pole tower and connected through the OPGW junction box. The OPGW junction box is connected to the emerging service communication equipment 800 installed on the strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com