A kind of microphase separated high temperature anhydrous ion conductive nanocomposite and its preparation and application

A technology of micro-phase separation and conductive nano-technology, which is applied in non-aqueous electrolytes, circuits, fuel cells, etc., to achieve the effects of ensuring efficient delivery, easy control of product process quality, and conducive to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

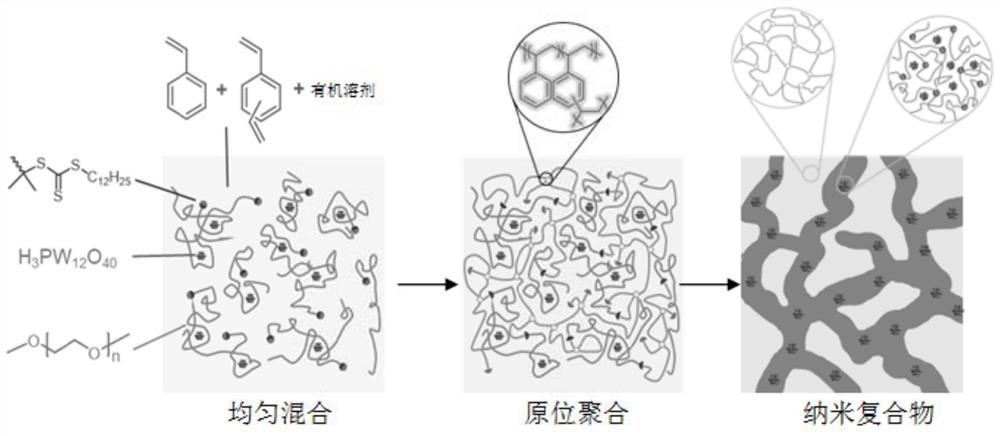

Method used

Image

Examples

Embodiment 1

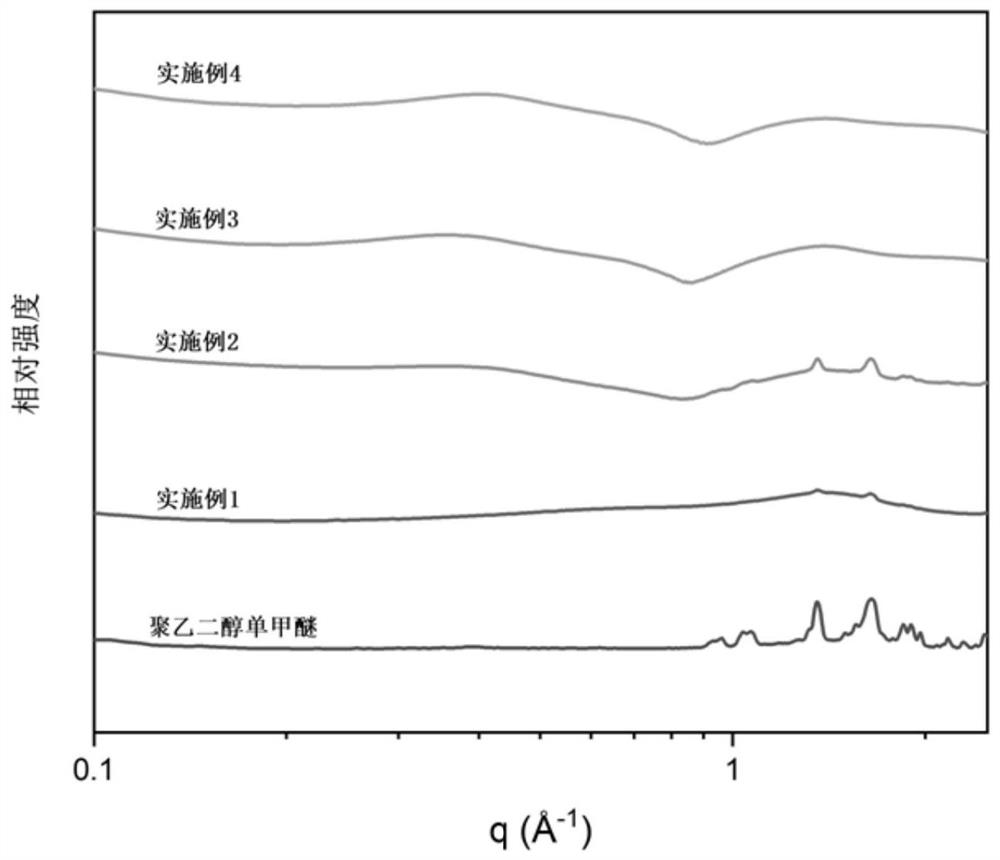

[0059] Dissolve 0.9 g polyethylene glycol-based macroinitiator (the molecular weight of polyethylene glycol monomethyl ether is 5000 g / mol), 2 mL styrene, 0.5 mL divinylbenzene and 3 mg azobisisobutyronitrile in 1 mL acetonitrile In the double-row tube, the oxygen was removed by liquid nitrogen freezing-vacuuming cycle three times, and after 70 °C oil bath heating and stirring reaction for 12 hours, the obtained solid was put into a vacuum oven for drying for 12 hours to obtain a composite material.

Embodiment 2

[0061] Put 0.1 g molecular cluster H 3 [PW 12 O 40 ]·6H 2 O, 0.9g polyethylene glycol-based macroinitiator (the molecular weight of polyethylene glycol monomethyl ether is 5000g / mol), 2mL styrene, 0.5mL divinylbenzene and 3mg azobisisobutyronitrile were dissolved in 1mL In acetonitrile, the oxygen was removed by liquid nitrogen freezing-vacuuming cycle three times on a double-row tube, and after the reaction was heated and stirred in an oil bath at 70 °C for 12 hours, the obtained solid was put into a vacuum oven for drying for 12 hours to obtain high temperature anhydrous ionic conductivity. Nanocomposites.

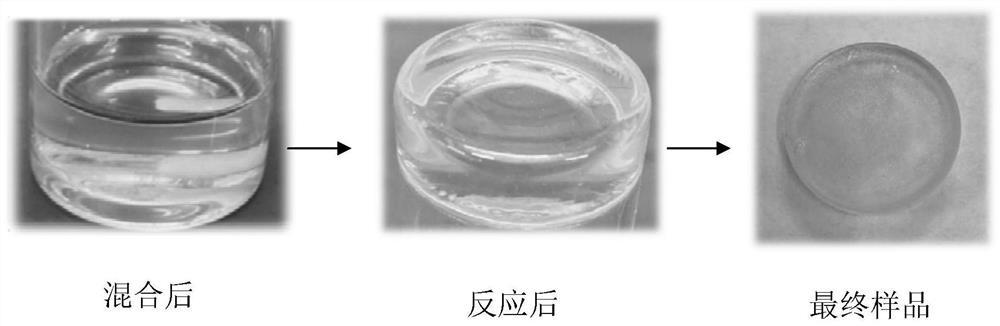

[0062] The optical diagram of the high-temperature anhydrous ion conductive nanocomposite prepared in this example is as follows: figure 2 shown.

Embodiment 3

[0064] 0.3857g molecular cluster H 3 [PW 12 O 40 ]·6H 2 O, 0.9g polyethylene glycol-based macroinitiator (the molecular weight of polyethylene glycol monomethyl ether is 5000g / mol), 2mL styrene, 0.5mL divinylbenzene and 3mg azobisisobutyronitrile were dissolved in 1mL In acetonitrile, the oxygen was removed by liquid nitrogen freezing-vacuuming cycle three times on a double-row tube, and after the reaction was heated and stirred in an oil bath at 70 °C for 12 hours, the obtained solid was put into a vacuum oven for drying for 12 hours to obtain high temperature anhydrous ionic conductivity. Nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com