High-voltage shielding cable connector structure of motor controller

A technology of cable connectors and motor controllers, which is applied in the direction of connection, parts of connection devices, protective grounding/shielding devices of connection parts, etc., to achieve the effects of convenient installation, reliable sealing, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

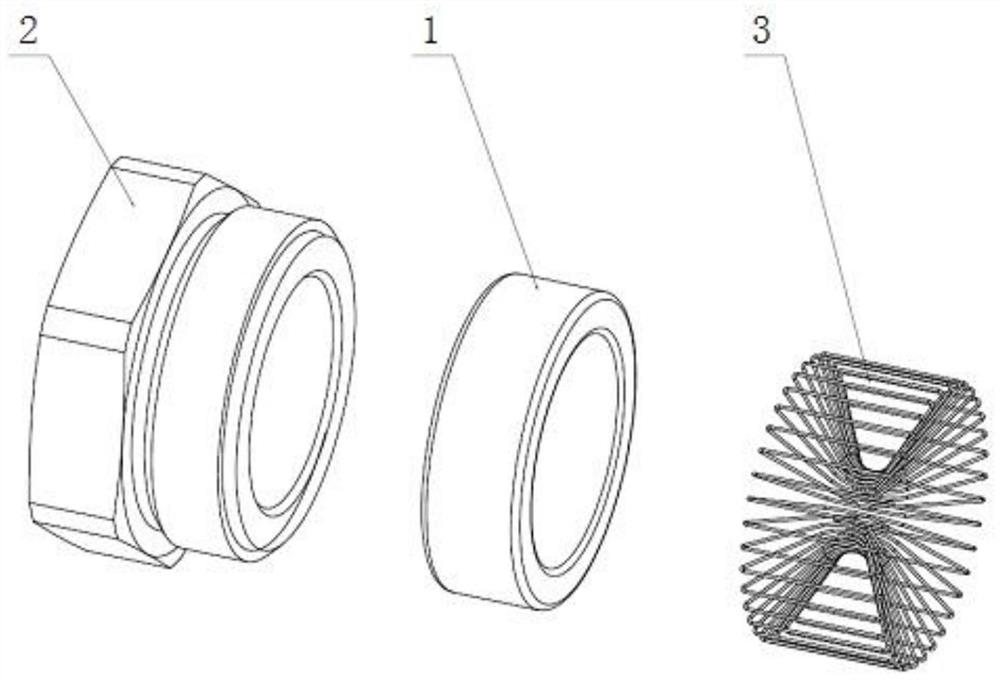

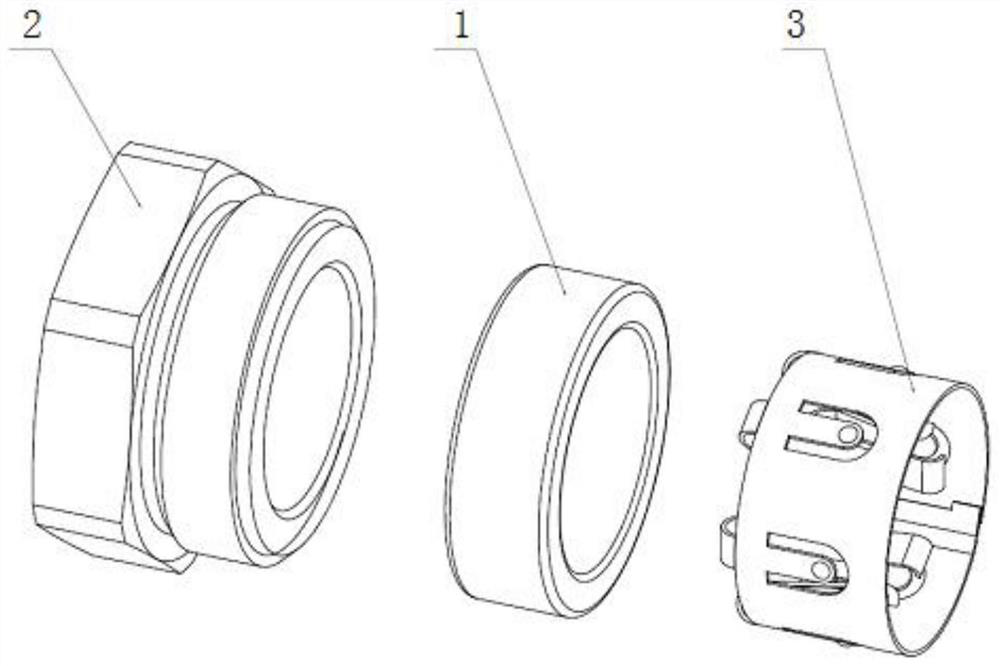

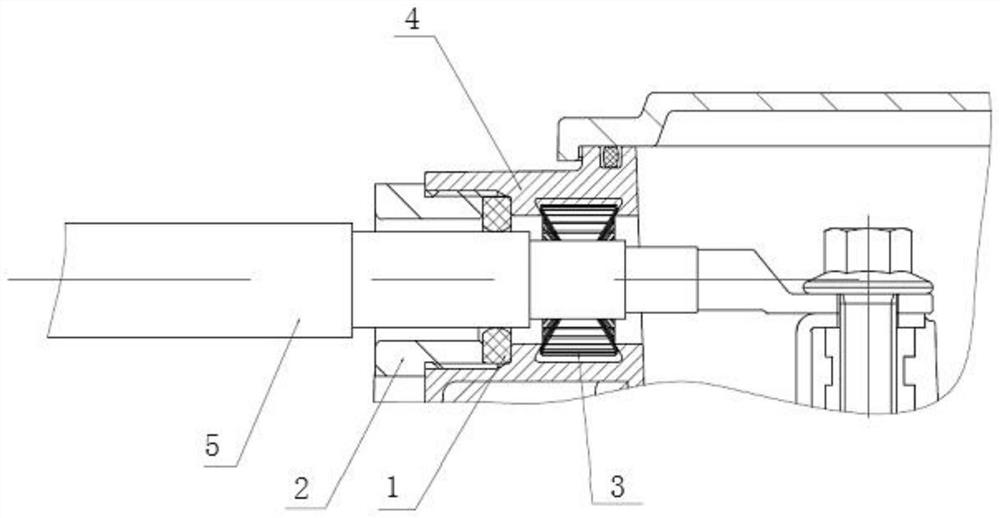

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a motor controller high-voltage shielded cable connector structure provided in an embodiment of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the structure can include:

[0035] Inner core 1, the inner core 1 is located inside the threaded hole on the controller housing 4;

[0036] A fastener 2, the fastener 2 includes an externally threaded section, and the externally threaded section is used to achieve a mating connection with the threaded hole;

[0037] Wherein, the material of the inner core 1 is a deformable material, and the material of the fastener 2 is plastic; the two end faces of the inner core 1 are respectively connected to the end faces of the fastener 2 and the threaded holes. The bottom surfaces are in contact with each other; the fastener 2 is used to provide pressure to the inner core 1 to deform the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com