Seed germination method

A technology for seeds and seed quality, applied in germination equipment and other directions, can solve the problems of difficult separation, sticky PEG solution, low efficiency, etc., and achieve the effects of low cost, high processing efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

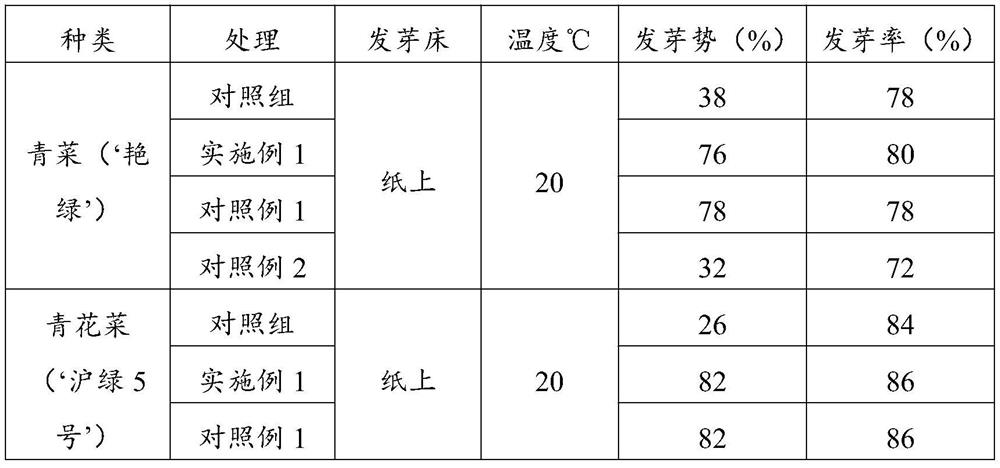

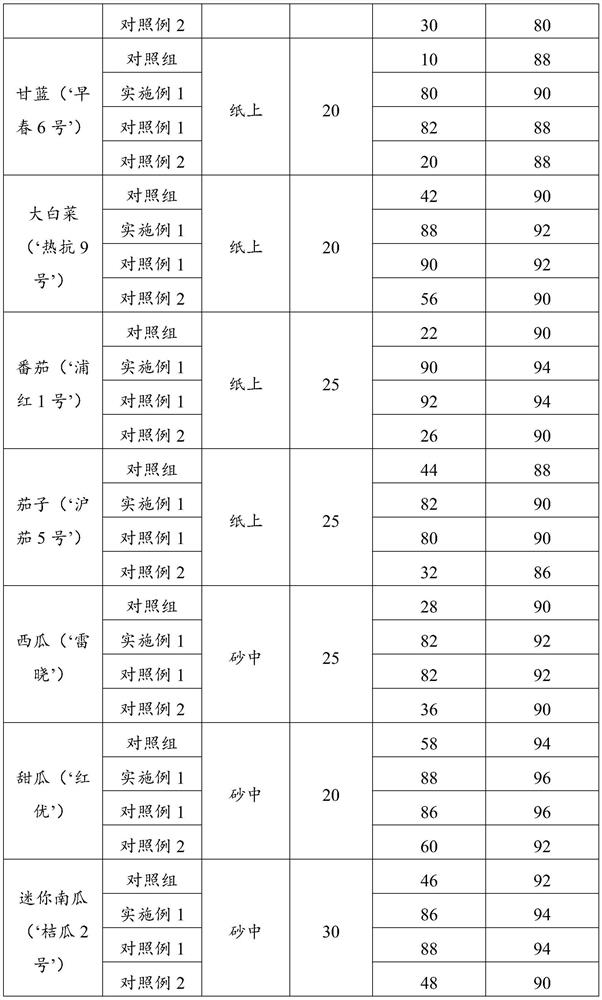

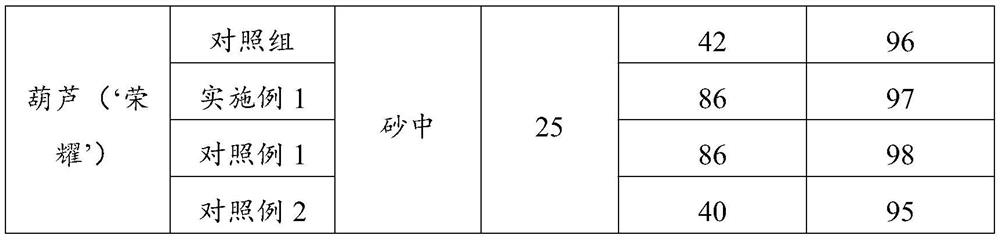

Examples

Embodiment 1

[0036] 1) Weigh 2000g of 'Yanlu' green vegetable seeds, 800g of 'Huqie No. 5' eggplant seeds, and 1200g of 'Leixiao' watermelon seeds and mix them evenly.

[0037] 2) Then pour 4000g of mixed seeds into an aluminum pot with a diameter of 40cm, spray water on the surface of the seed mixture with a sprayer equipped with 1600ml of water, and stir the mixture at the same time.

[0038] 3) Put the aluminum pot into the incubator, set the temperature at 15°C, stir the seed mixture once every 12 hours, cultivate for 72 hours, and then use a belt cleaner to separate the green vegetable seeds from the eggplant and watermelon seeds (the green vegetable seeds absorb water Finally, it is full and round, easy to roll on the inclined belt and can be separated from flat seeds), put the green vegetable seeds in a drying box at 30°C and dry them back to a moisture content of 7% or less, then seal them for storage. Eggplant and watermelon seeds were poured into the aluminum pot and placed in th...

Embodiment 2

[0040] 1) Weigh 2000g of 'Shanglv No. 5' broccoli seeds, 1000g of 'Puhong No. 1' tomato seeds, 1000g of 'Jugua No. 2' mini pumpkin seeds and mix well.

[0041] 2) Then pour 4000g of mixed seeds into an aluminum pot with a diameter of 40cm, spray water on the surface of the seed mixture with a sprayer equipped with 2000ml of water, and stir the mixture at the same time.

[0042] 3) Put the aluminum pot into the incubator, set the temperature at 20°C, stir the seed mixture once every 12 hours, cultivate for 48 hours, and then use a belt cleaner to separate the broccoli seeds from the tomatoes and mini pumpkin seeds. Cauliflower seeds are put into a drying box at 30°C and dried back until the moisture content is below 7%, and then sealed for storage. Continue to pour tomato and mini pumpkin seeds into the aluminum pot and put them into the culture. The temperature is still set at 20°C. After continuing to cultivate for 48 hours, put the seeds in the drying box at 32°C and dry the...

Embodiment 3

[0044] 1) Weigh 3000g of selected cabbage seeds and 1000g of 'Glory' gourd seeds and mix well.

[0045] 2) Then pour 4000g of mixed seeds into an aluminum pot with a diameter of 40cm, spray water on the surface of the seed mixture with a sprayer equipped with 2400ml of water, and stir the mixture at the same time.

[0046] 3) Put the aluminum pot into the incubator, set the temperature at 15°C, stir the seed mixture once every 12 hours during the period, cultivate for 72 hours, use an 8-mesh round hole sieve (3mm) to separate the cabbage and gourd seeds, put the cabbage seeds in Dry in a drying oven at 28°C until the moisture content is below 7%, and then seal and store for later use. The gourd seeds continue to be cultivated for 48 hours, and then put them in a drying oven at 35°C for drying until the moisture content is below 7%, and then seal and store for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com