Oven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

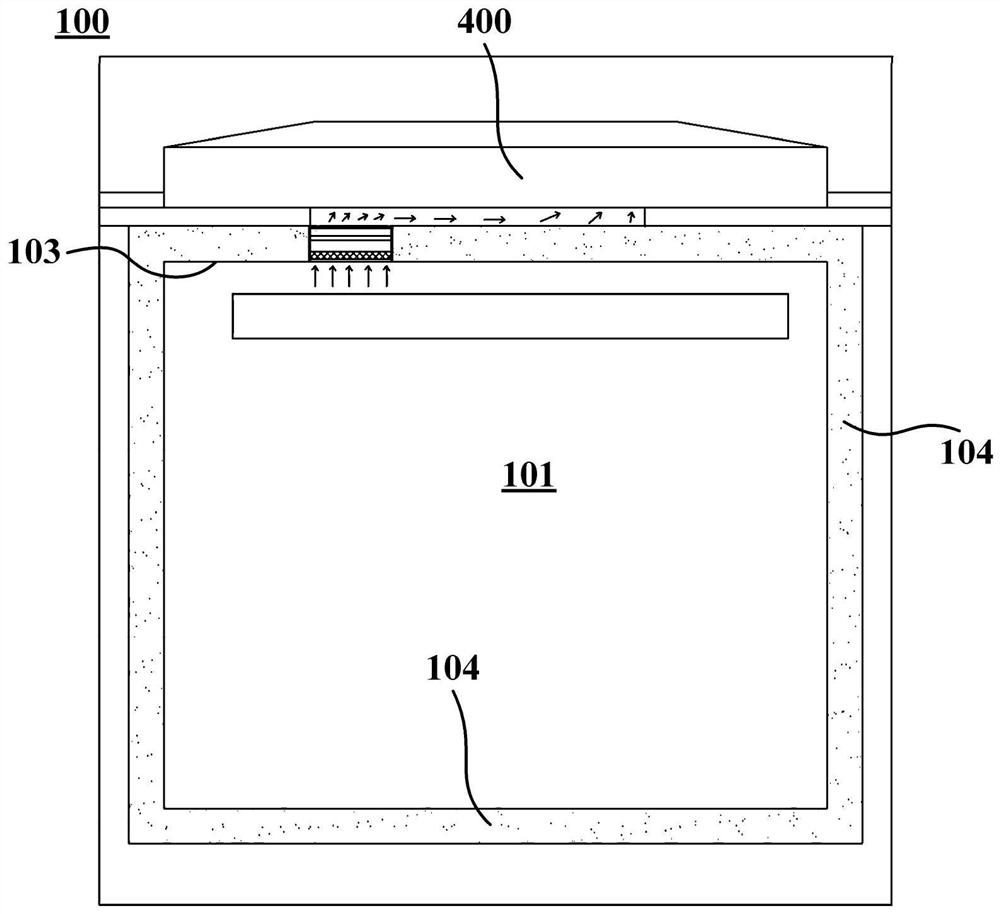

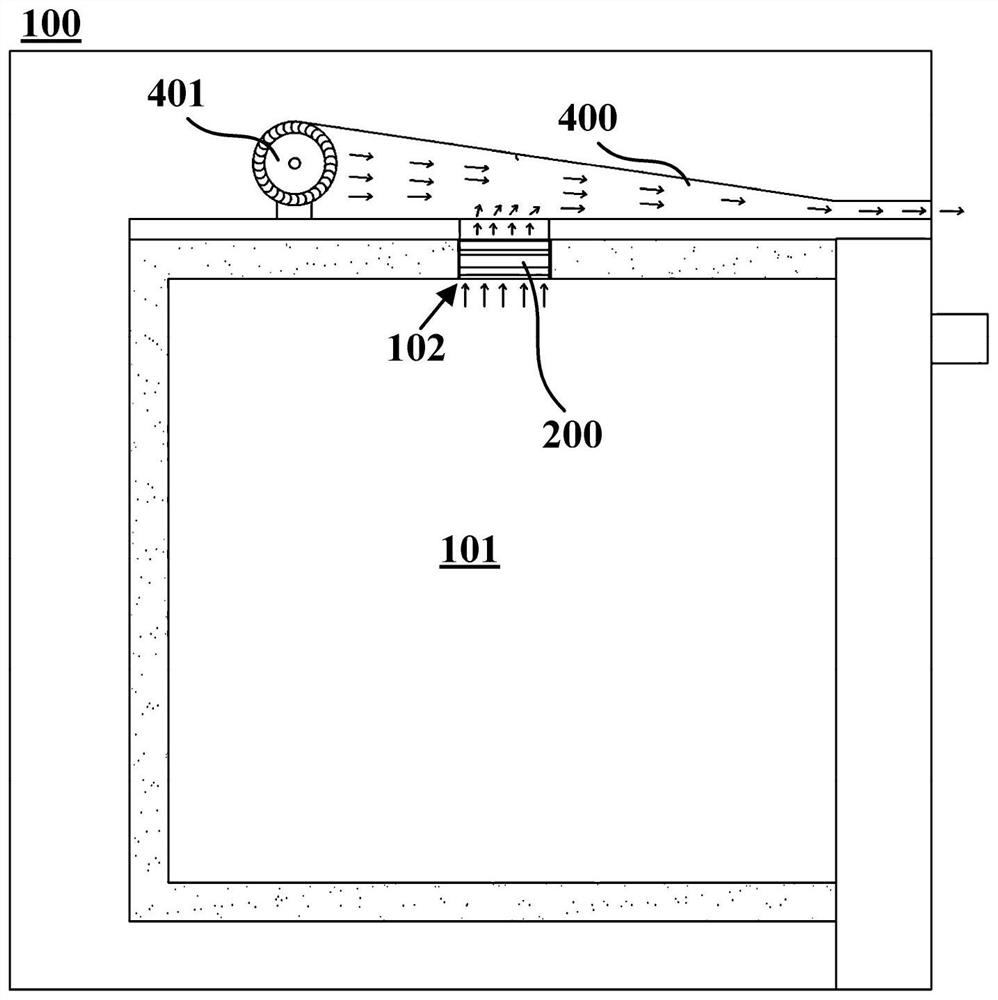

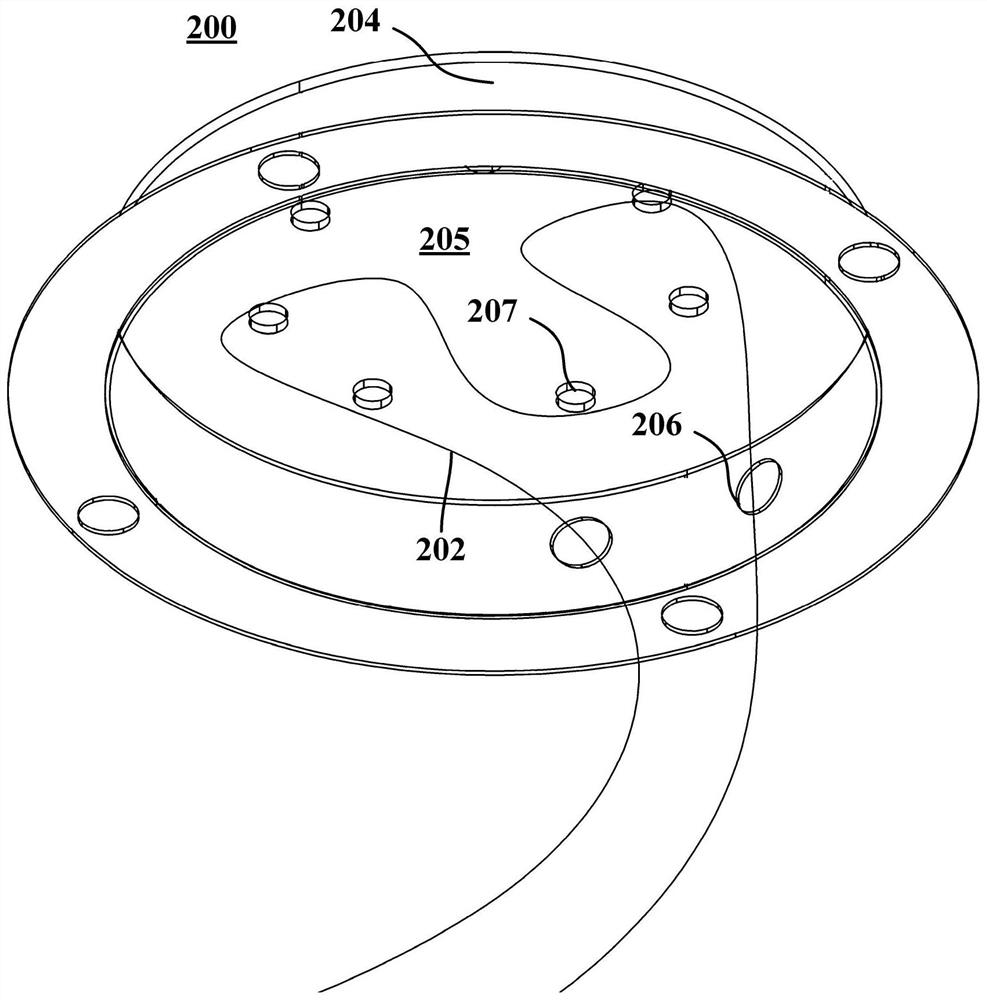

[0051] figure 1 is a schematic front view of an oven 100 according to an embodiment of the present invention, figure 2 is a schematic side view of an oven 100 according to an embodiment of the present invention, in order to show part of the internal structure of its housing 204, figure 1 and figure 2 The casing 204 of the oven 100 is partially cut away. The oven 100 may generally include a process chamber 101 and a smoke removal module 200 . The processing chamber 101 carries the object to be processed, and the object to be processed is baked by the heating device. A wall 103 of the processing chamber 101 may be provided with an air hole 102 for exhausting oily fume generated from the processing chamber 101 when the food is baked. The smoke removal module 200 is disposed in the processing chamber 101 and is configured to receive oil fumes discharged from the processing chamber 101 . Specifically, the smoke removal module 200 is arranged adjacent to the outside of a wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com