Silicon carbide reflector modification machining and detection control system and method

A technology of silicon carbide and mirrors, applied in the control of workpiece feed movement, metal processing equipment, lenses, etc., can solve problems such as complex processing and inspection procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

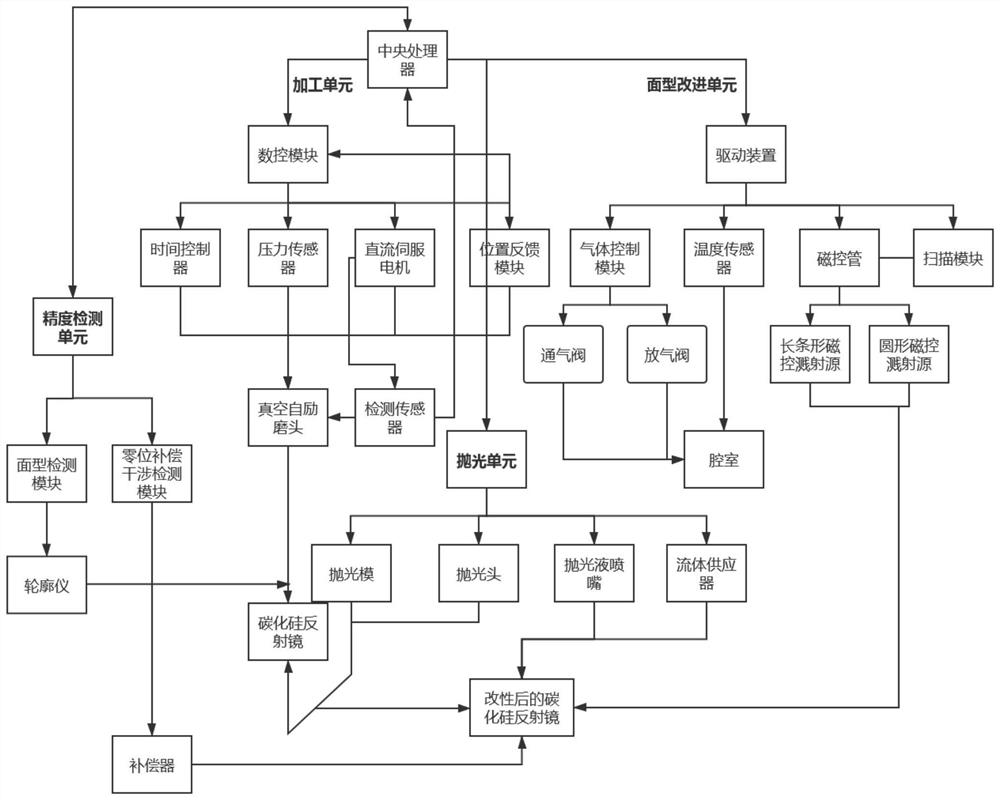

AI Technical Summary

Problems solved by technology

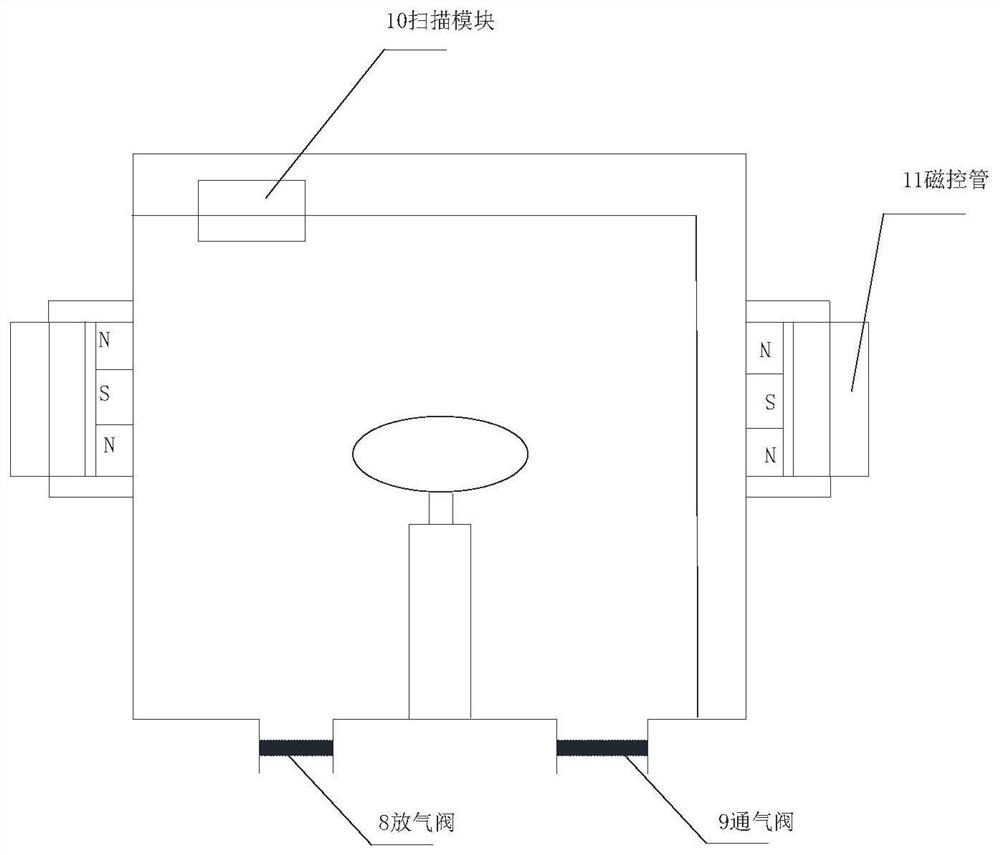

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0023] A silicon carbide mirror to be processed, with a size of 400×250 mm and an off-axis ellipsoidal surface, is placed on the processing table.

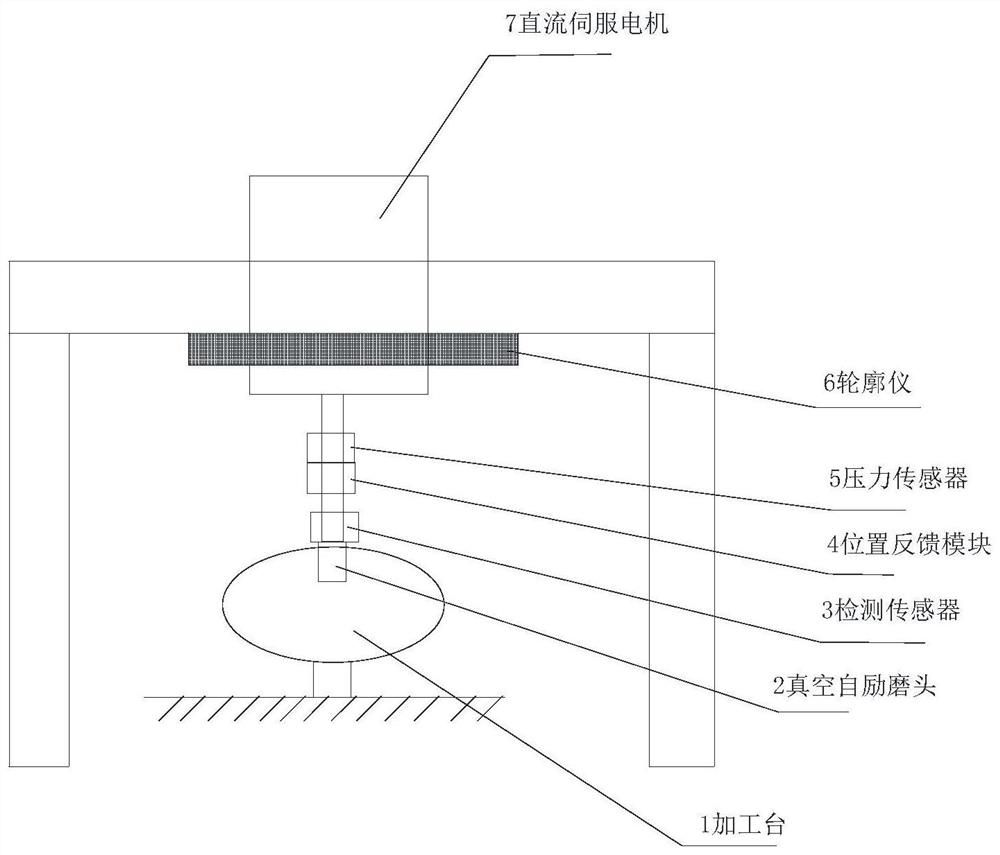

[0024] First enter the grinding stage, you need to call the processing unit. The central processor commands the numerical control module to control the DC servo motor so that the vacuum self-excited grinding head rotates and grinds the silicon carbide mirror, and the time controller, pressure sensor and position feedback module are used to control the vacuum self-excited grinding head on the surface of the silicon carbide mirror. The time, depth and position of the sanding can be controlled to control the sanding process. The detection sensor is set above the vacuum self-exciting grinding head, and it needs to be detected once in a while. When the detection sensor is detected to be in contact with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com