Flat-rotating flipping de-energizing mechanism, automatic liquid dispensing robot

A turning mechanism and horizontal rotation technology, which is applied in the direction of mixer accessories, mixers, manipulators, etc., can solve the problems of inability to turn over operations, waste of time, and poor shaking effect of liquid medicine, etc., to achieve batch operation and improve work efficiency , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the embodiments, technical solutions and advantages of the present invention more obvious, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. Example. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

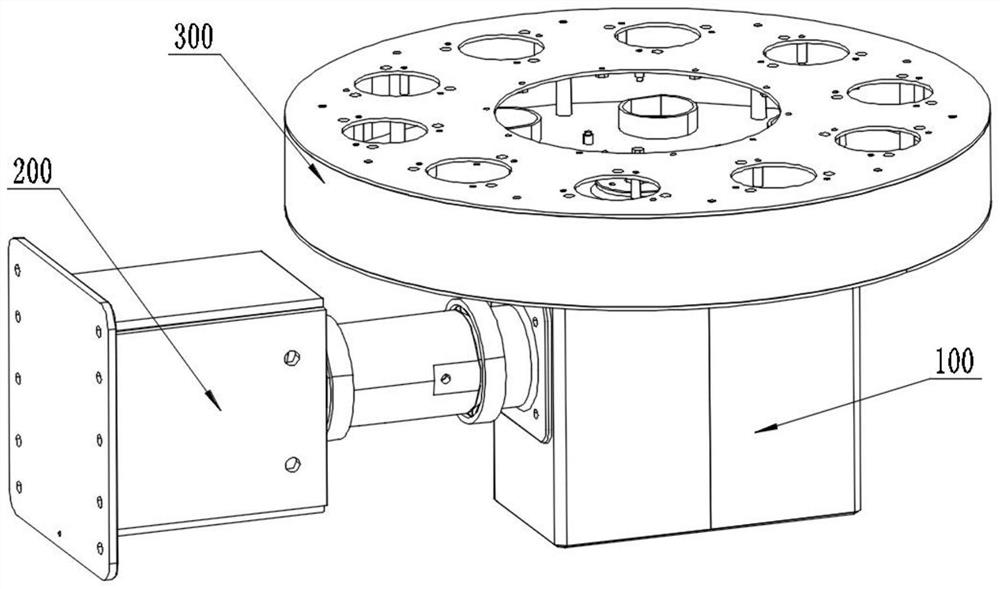

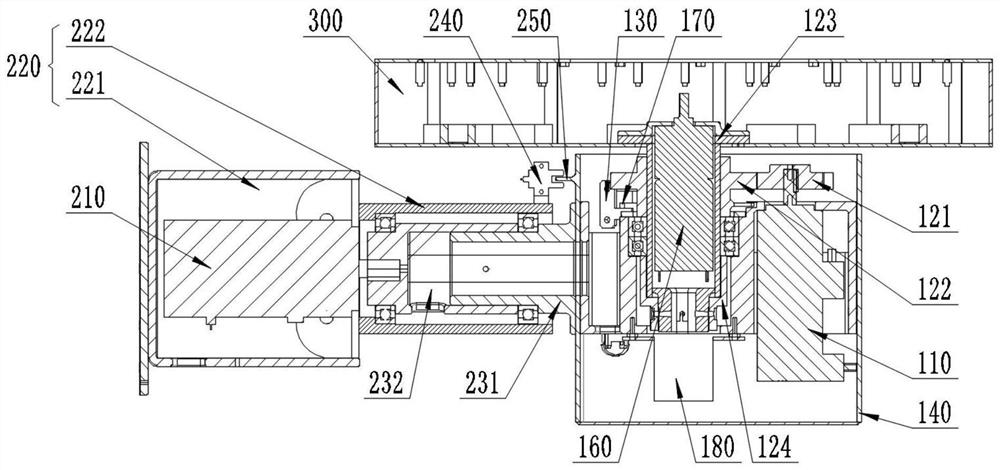

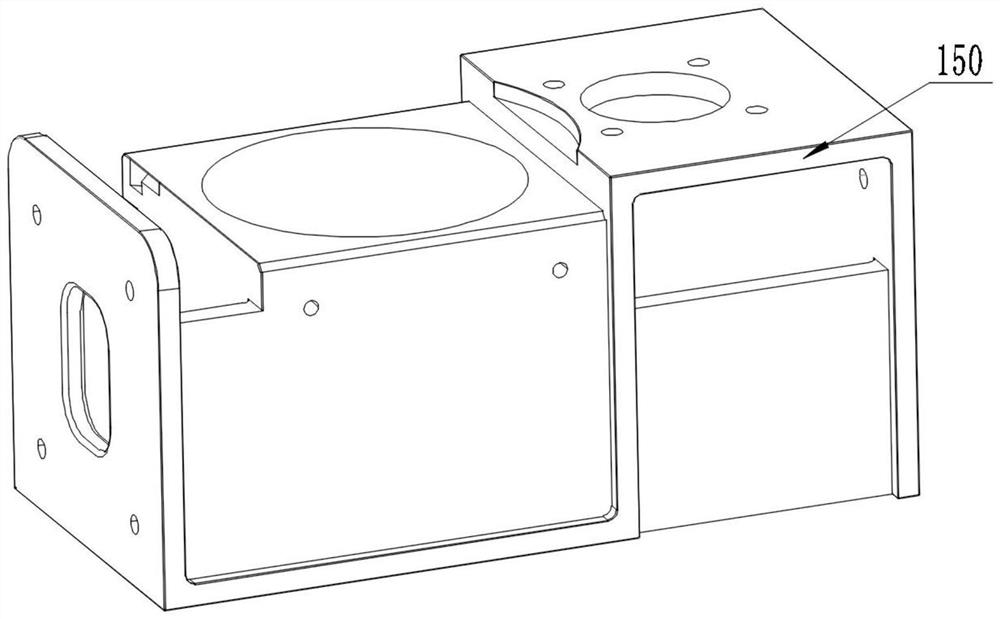

[0034] The first aspect of the present invention provides a flat-rotation flipping de-energization mechanism, which includes a flat-rotation mechanism, a flip mechanism, and a general control device. The received panning or flipping instructions control the panning mechanism or the flipping mechanism to perform the corresponding panning or flipping motion. The horizontal rotation mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com