Mixed medicine liquid processing equipment

A technology for processing equipment and mixing drugs, applied in the medical field, can solve problems such as low work efficiency, overflow of mixed drug liquid, low utilization rate of human resources, etc., and achieve the effect of saving labor and preventing overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

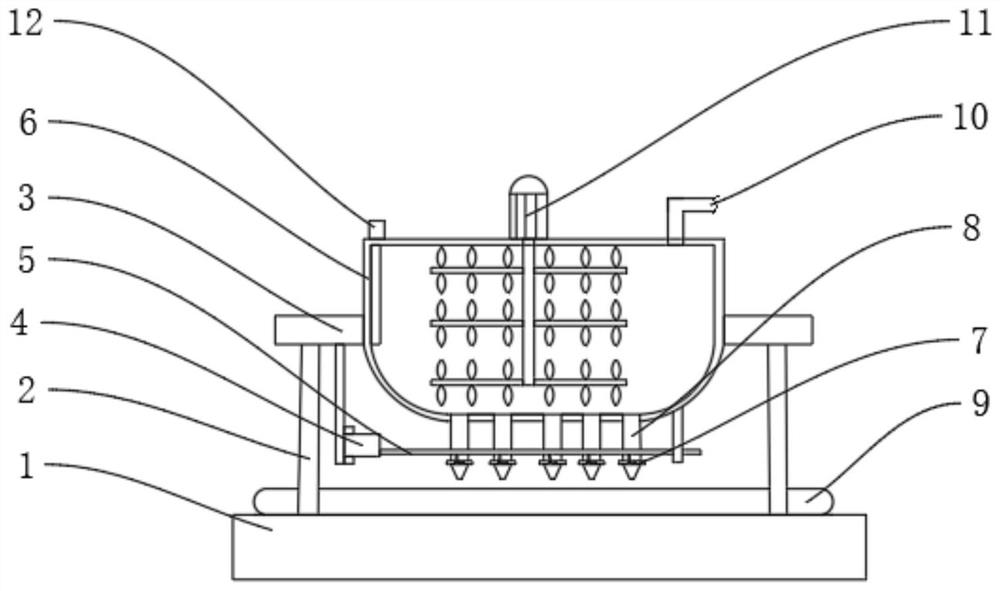

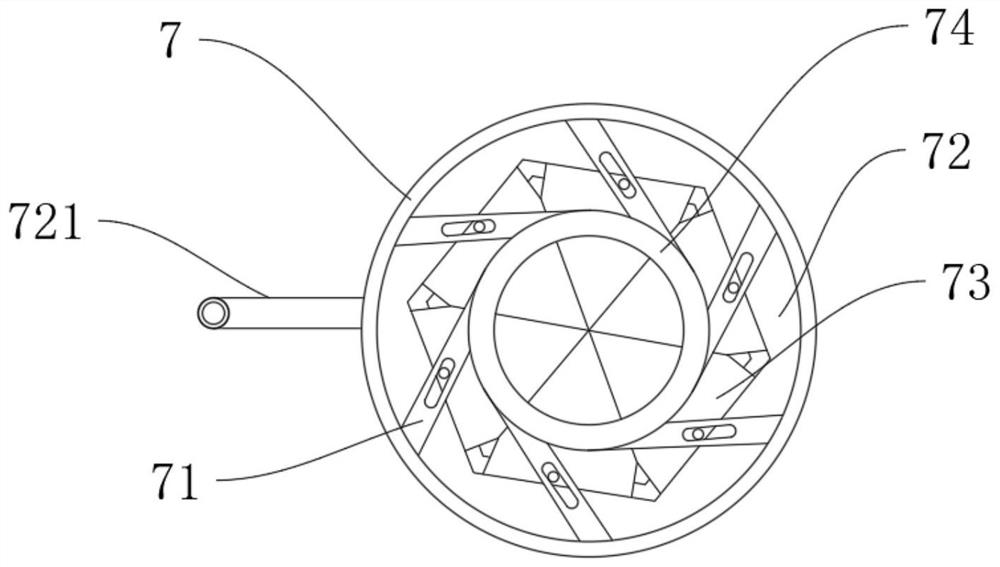

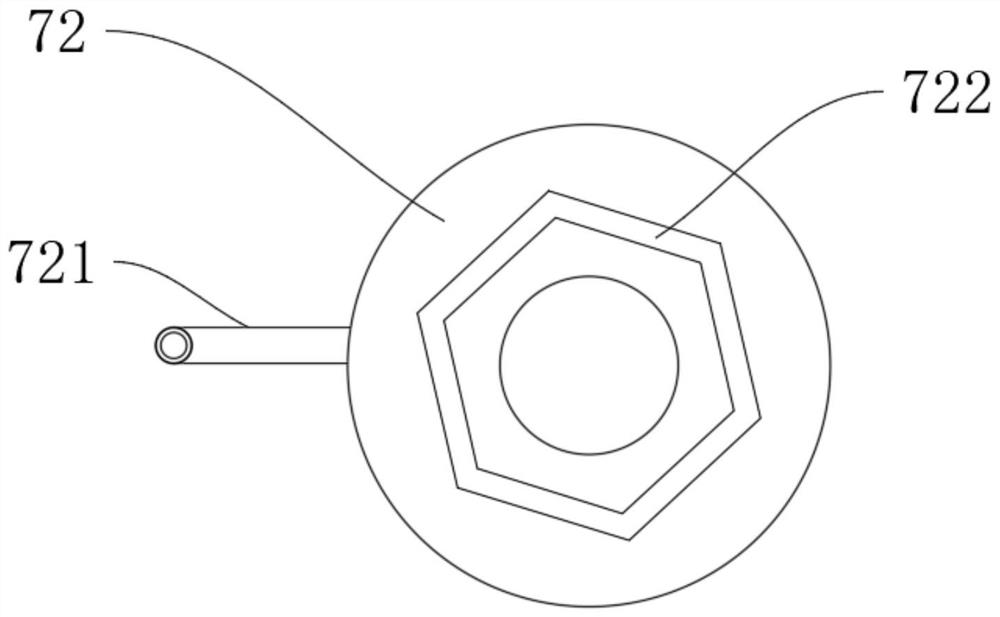

[0028] refer to Figure 1-7 , a mixed drug liquid processing equipment, comprising a base 1, characterized in that the top of the base 1 is fixedly connected to a first support rod 2, the top wall of the first support rod 2 is connected to a support plate 3, and the outer wall of the support plate 3 is connected to There is a filling box 6, the bottom of the filling box 6 is plugged with a discharge pipe 8, the inner wall of the discharge pipe 8 is connected with a quantitative valve 7, the top wall of the quantitative valve 7 is connected with a limiting plate 71, and the inner wall of the quantitative valve 7 is movably connected with a Turning plate 72, the top wall of turning plate 72 is dug with first chute 722, and the inner wall of first chute 722 is slidably connected with clamping plate 73, and the top of clamping plate 73 is connected with slide block, and slide block is positioned at limit plate 71 and opens. In the limiting hole, the outer wall of the rotating plat...

Embodiment 2

[0033] refer to figure 1 , Figure 6 and Figure 7 , a mixed drug liquid processing equipment, which is basically the same as in Example 1, furthermore, the top of the filling box 6 is provided with a feeding port 10, the inner wall of the filling box 6 is connected with a stirring device 11, and the filling box 6 The inner wall is connected to the automatic feeding switch 12, and the outer wall of the feeding port 10 is connected to multiple sets of feeding pipes; the mixture enters the feeding port 10 through multiple groups of feeding pipes, and then the feeding port 10 transports the mixed drug liquid to the filling box 6 Inside, after the delivery of the mixed drug liquid is completed, the mixed drug liquid in the filling tank 6 is stirred by the stirring device 11, which can prevent the mixed drug liquid from having poor uniformity and low quality.

Embodiment 3

[0035] refer tofigure 1 and Figure 6 , a mixed drug liquid processing equipment, which is basically the same as that of Embodiment 1, furthermore, the automatic feeding switch 12 includes a water float switch 121, a protection tube 122, a first water float 123 and a second water float 124, The first water float 123 and the second water float 124 are connected by a rope, the end of the first water float 123 away from the second water float 124 is connected to the bottom wall of the water float switch 121, and the protection tube 122 is connected to the bottom wall of the water float switch 121. The inner top wall of the box 6 , the first water buoyant ball 123 and the second water buoyant ball 124 are located on the inner wall of the protection tube 122 .

[0036] The top of the base 1 is connected with a transportation device 9 .

[0037] Through the cooperation of the water float switch 121, the protection tube 122, the first water float 123 and the second water float 124, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com