Coiled material supply device for flexible circuit board production

A technology of flexible circuit boards and supply devices, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., and can solve problems such as increased space occupation, large position offset, and increased probability of coil position offset. , to achieve the effect of compressing space occupation, improving splicing efficiency, and ensuring splicing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

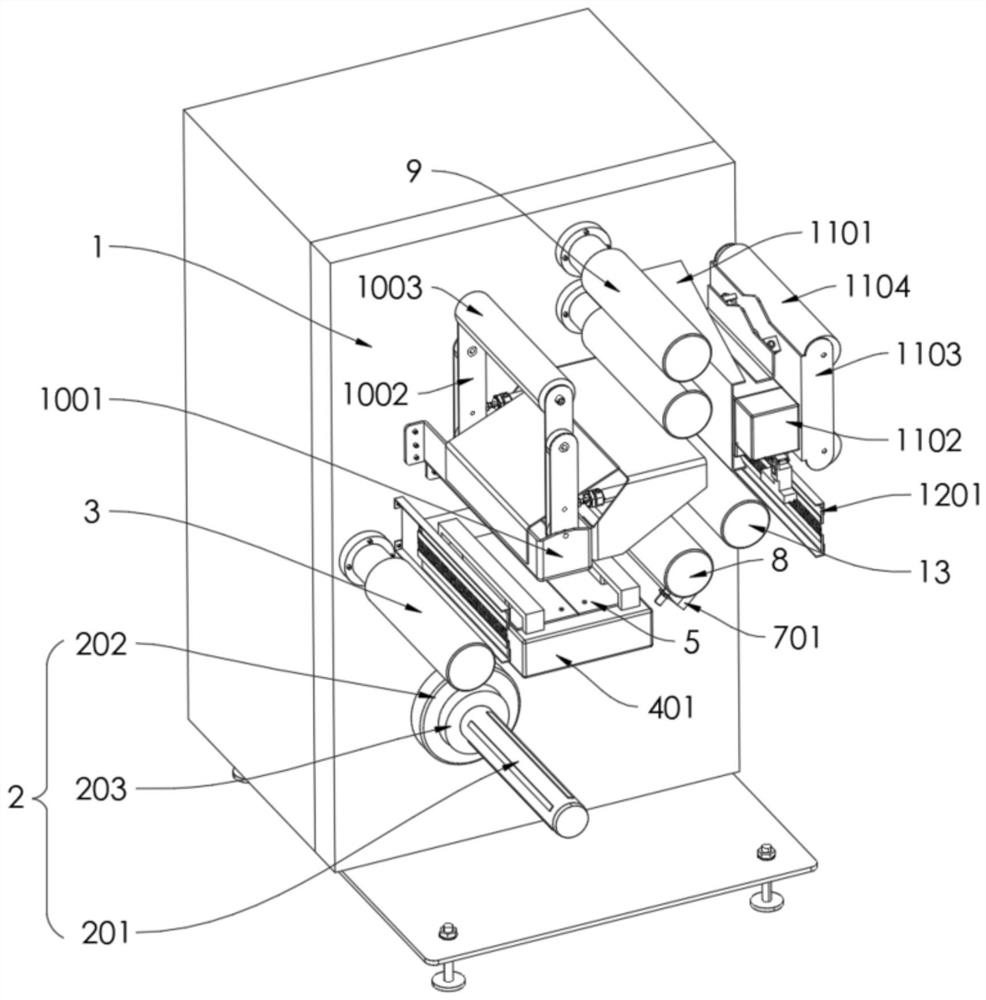

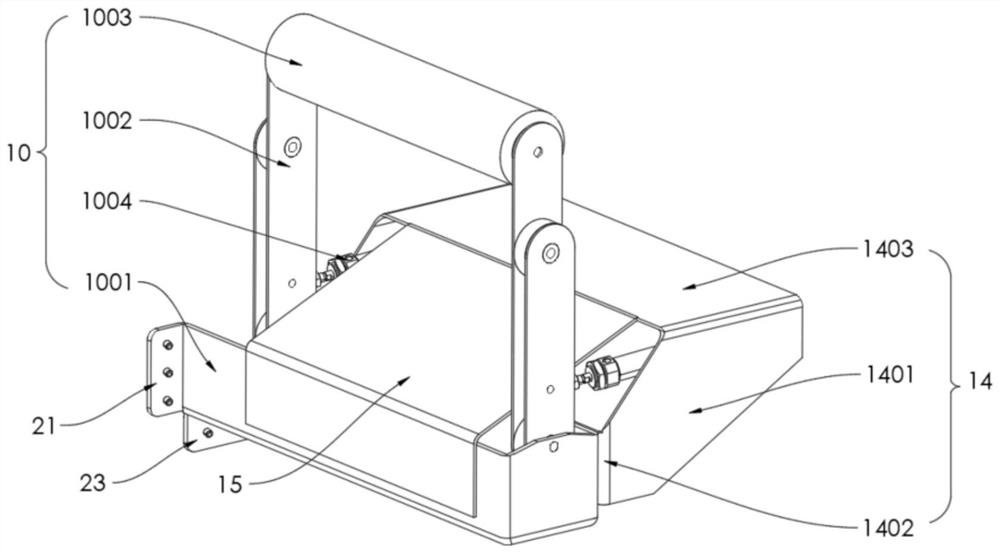

[0049] refer to Figure 1-8 , a coil supply device for flexible circuit board production, comprising

[0050] Support plate 1;

[0051] A coil support mechanism 2, the coil support mechanism 2 includes an air expansion shaft 201 rotatably mounted on the support plate 1;

[0052] The first guide roller 3 is rotatably mounted on the support plate 1, and the first guide roller 3 is located above the front side of the air shaft 201;

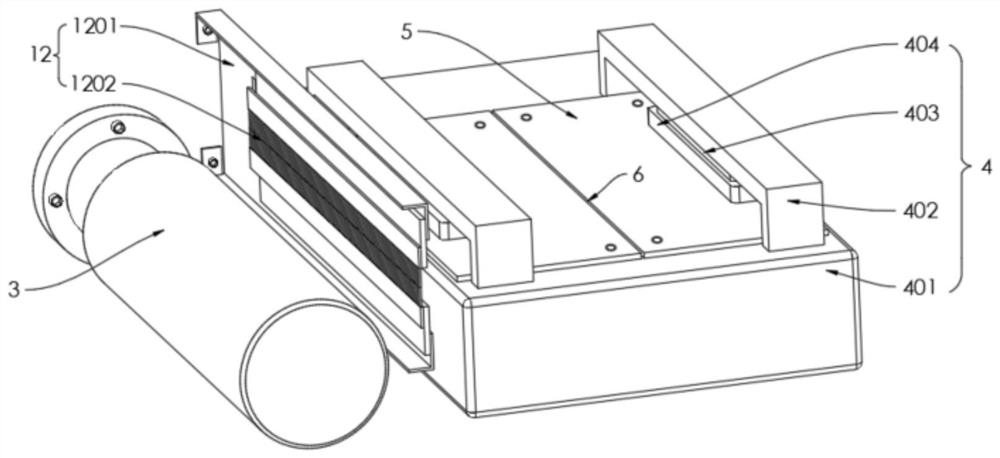

[0053] The coil splicing mechanism 4 is arranged on the rear side of the first guide roller 3. The coil splicing mechanism 4 includes a fixing part 401 fixed on the support plate 1, and the upper surface of the fixing part 401 is arranged in a planar shape. The upper side of the front and rear end of the fixing member 401 is resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com