Mold heat treatment equipment

A technology of heat treatment equipment and molds, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve problems such as uneven heating of molds, decline in mold strength and hardness, etc., to improve feeding efficiency and safety, and increase strength and hardness, and the effect of improving the rotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

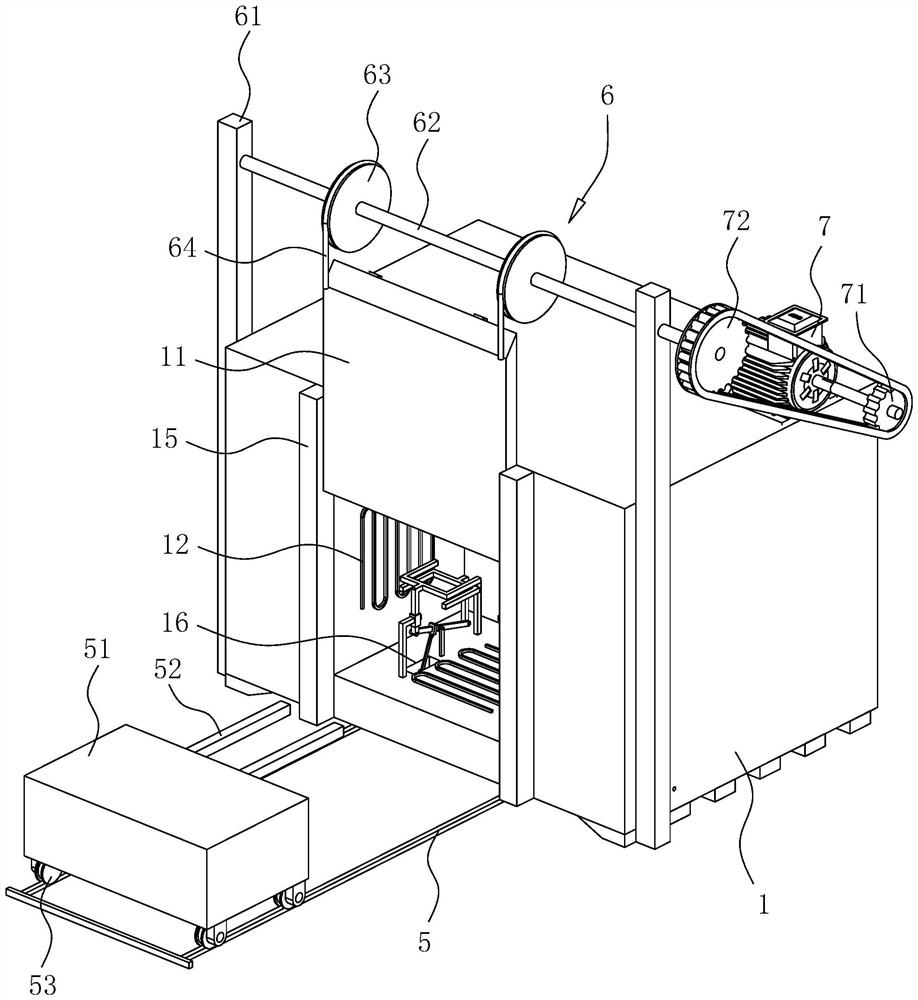

[0036] The following is attached Figure 1-4 The application is described in further detail.

[0037] The embodiment of the present application discloses a mold heat treatment equipment.

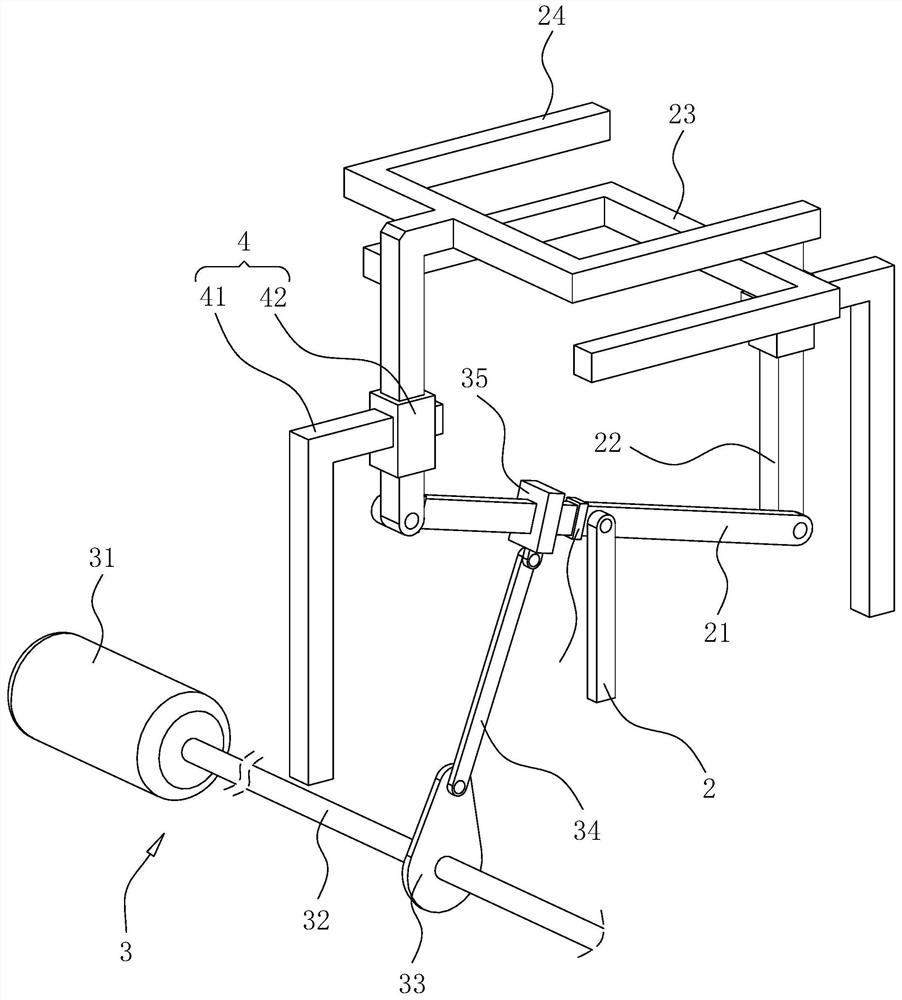

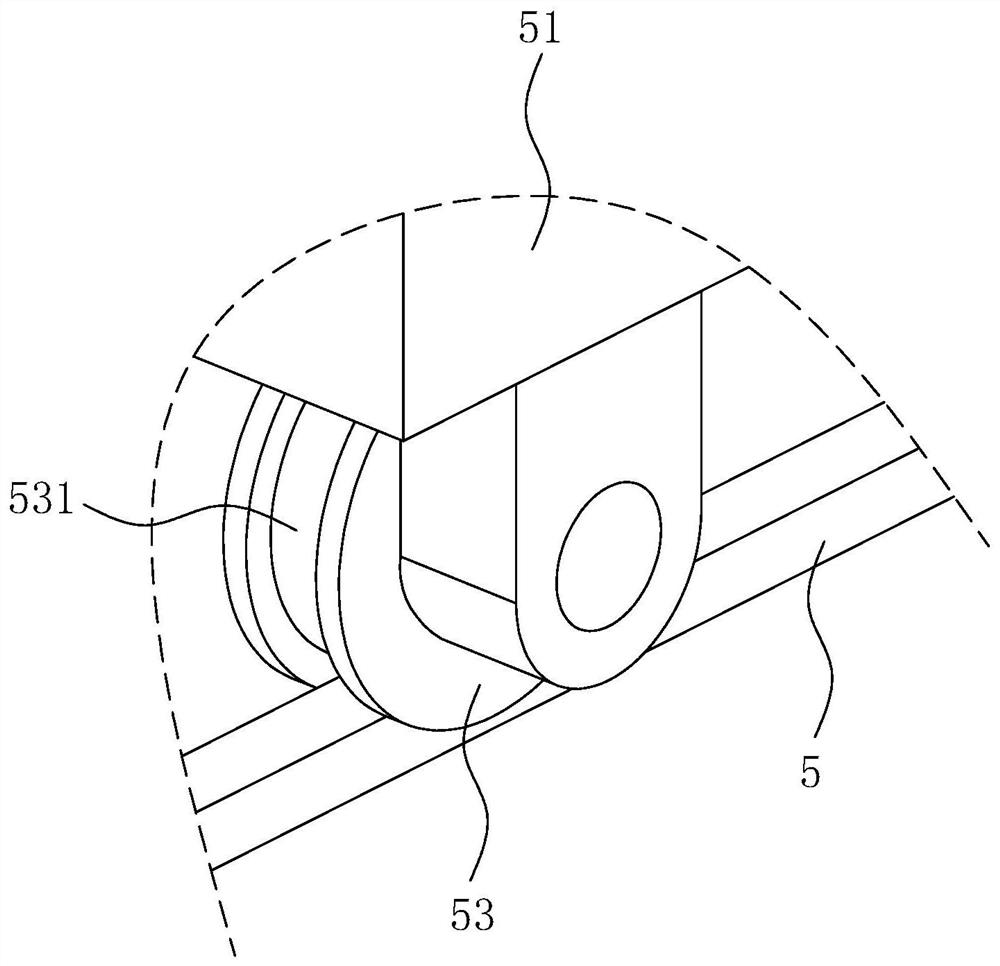

[0038] refer to figure 1 and figure 2A kind of mold heat treatment equipment includes a furnace body 1 with one side opening, the side wall at the opening of the furnace body 1 is vertically slidably connected with a furnace door 11 for opening and closing the furnace mouth, and the inner wall of the furnace body 1 is fixed with a number of heating wires 12 , the top of the furnace body 1 is provided with a lifting mechanism 6 for driving the furnace door 11 to lift; The two levers 21 are parallel to each other, the middle part of the lever 21 is hinged with the top of the support rod 2, and the hinge axis of the lever 21 is horizontally arranged, and the two ends of the lever 21 are hinged with a vertically arranged connecting rod 22, and the hinge axes of the connecting rod 22 are unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com