Static pile press machine for guiding hole and excavating in middle and construction method thereof

A technology of static pile driver and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve problems such as inability to drill, consume long time, affect construction progress, etc. Design requirements and the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

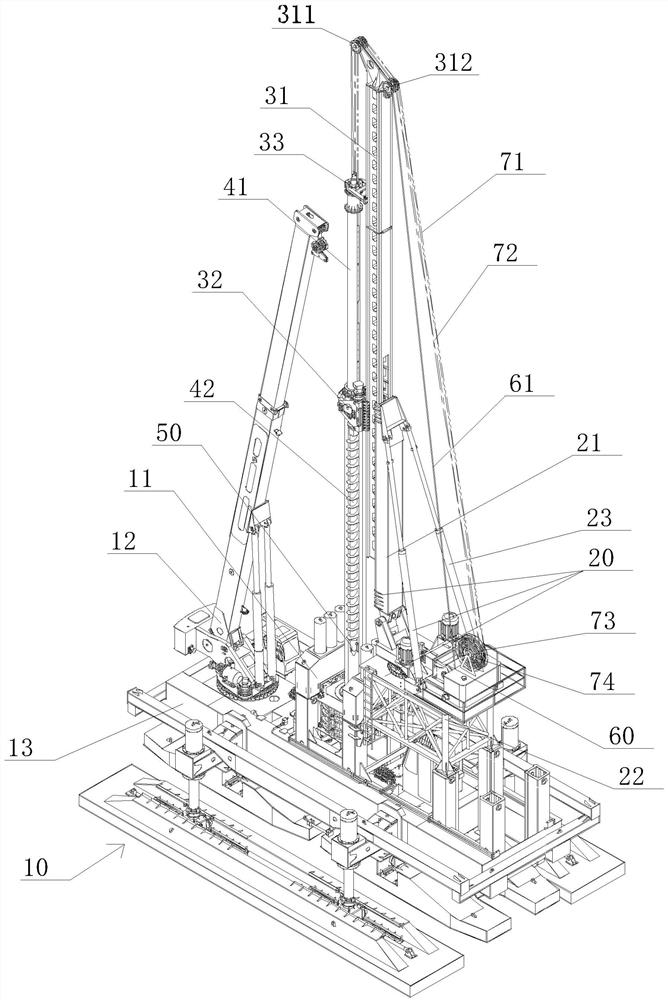

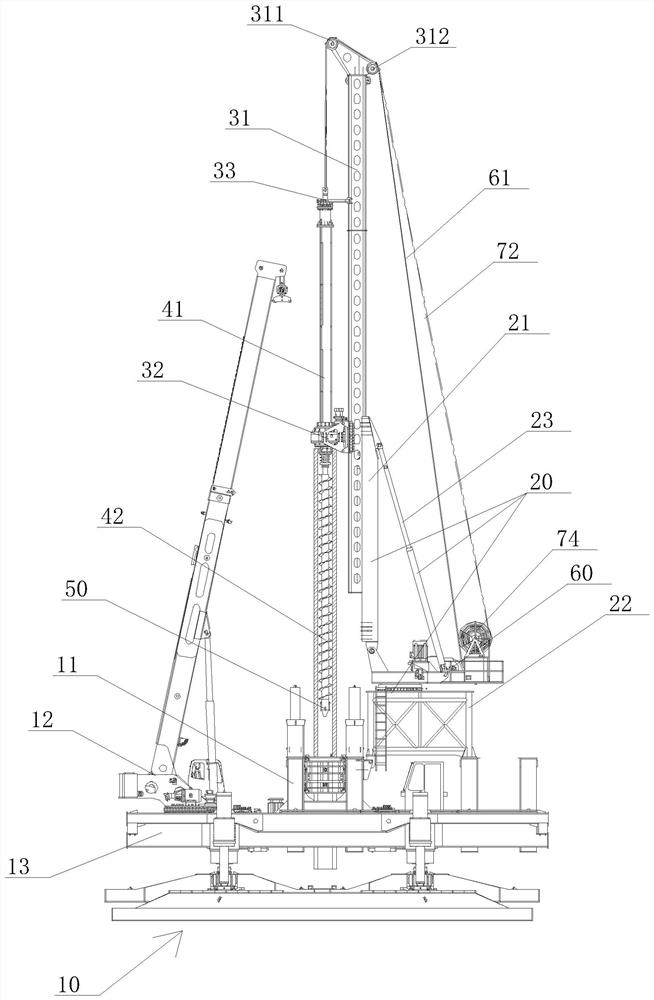

[0056] see Figure 1 to Figure 10 As shown, the construction method of digging static pile driver in the lead hole provided by the embodiment of the present invention comprises the following steps:

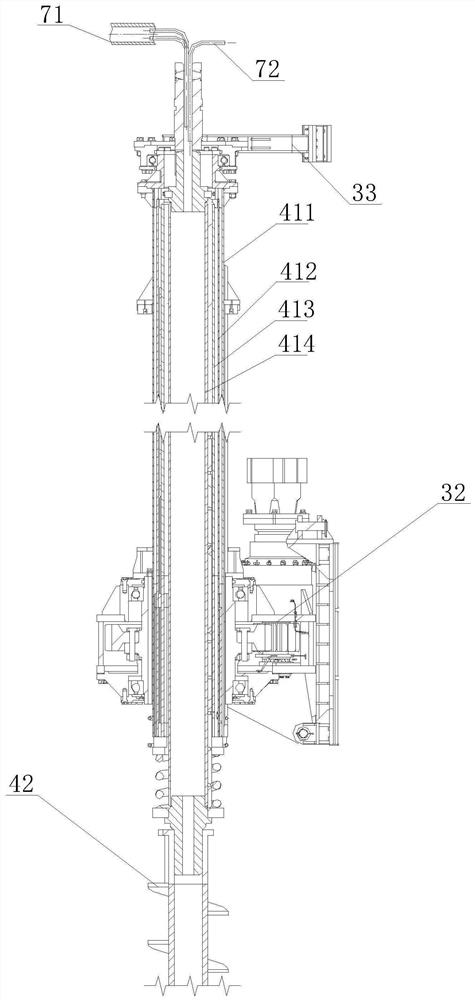

[0057] (1), the pile driver is in place, move the static pile driver in the lead hole to the area to be constructed, the static pile driver in the lead hole includes the static pile driver 10, the lead hole drill rod 41, and the auger drill rod 42. Bottom expansion drill bit 50, drill pipe hoist 60, fluid delivery pipe 72, static pile machine 10 includes hydraulic pile pressing mechanism 11, hoisting mechanism 12, bottom expansion drill bit 50 includes bottom expansion digging knife 53, cement release port 54, guides Hole drill rod 41, auger drill rod 42, and bottom expansion drill bit 50 are respectively hollow, and fluid conveying pipe 72 passes through pilot hole drill rod 41, auger drill rod 42, bottom expansion drill bit 50 and communicates with cement release port 54 in sequ...

Embodiment 2

[0077] The static pile driver and construction method thereof provided in the embodiment of the present invention are basically the same as those in Embodiment 1, except that:

[0078] The digging static pile driver in the lead hole also includes a down-the-hole hammer, and step (5) also includes the following steps:

[0079] (51), when it is difficult to excavate the bearing layer soil (encounter hard sand layer, hard rock layer) with the bottom-enlarging drill bit 50, replace the bottom-expanding drill bit 50 with the down-the-hole hammer, and the foundation soil layer 90 below the pipe pile 80 The hard sand layer or hard rock layer in the pipe is crushed and excavated, and then the pipe pile 80 is pressed into the bearing hard soil layer 92 with the hydraulic pressure pile mechanism 11. When replacing the bottom reaming bit 50 with a down-the-hole hammer, the fluid delivery pipe 72 can be used to connect an external air compressor with the down-the-hole hammer, and the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com