Combined type pressurization dehumidification system

A combined type, rotary dehumidifier technology, applied in air conditioning systems, heating methods, lighting and heating equipment, etc., can solve the problems of low dehumidification efficiency, achieve energy saving, high dehumidification capacity, and improve heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

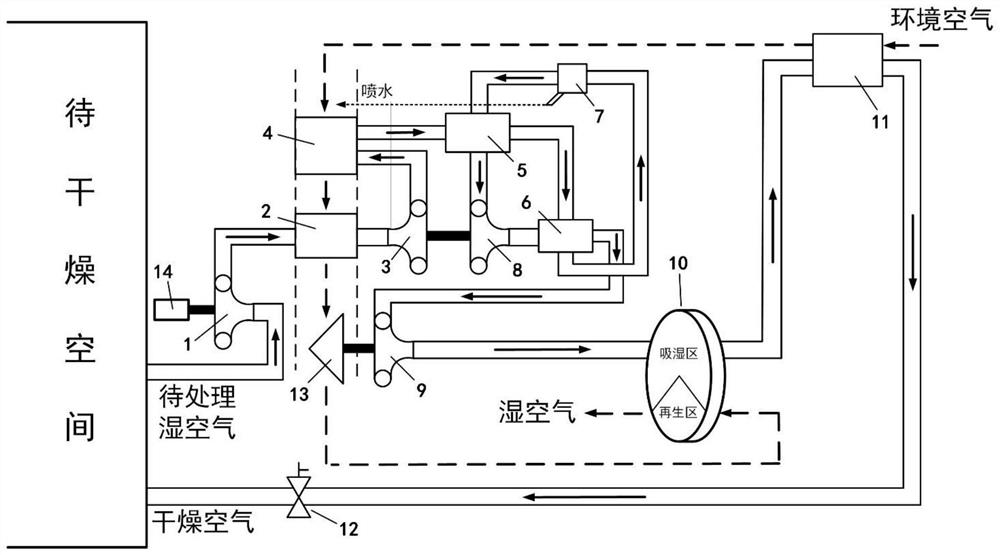

[0014] combine figure 1 Describe the specific working process of the system. When working, the humid air to be treated first enters the first-stage compressor 1 driven by the motor 14 to be compressed and heated up, then passes through the primary radiator 2 to cool down and cool down, and then enters the second-stage compressor 3 driven by the first-stage turbine 8 to be further compressed and heated up , and then cooled down through the secondary radiator 4. At this time, the humid air passes through the hot side of the regenerator A5 and the condenser 6 successively, is cooled down to below the dew point temperature of the current pressure, reaches a saturated state, and a large amount of free water is precipitated. After passing through the high-pressure water separator 7, the humid air The free water in the air is separated and sprayed to the cold side of the secondary radiator 4, and the humid air continues to pass through the cold side of the regenerator A 5 and then e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com