Test device for testing recovery efficiency of condensate on inner wall surface of nuclear power station containment vessel

A nuclear power plant containment and recovery efficiency technology, applied in the direction of measuring devices, electric devices, volume/mass flow generated by electromagnetic effects, etc., to achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

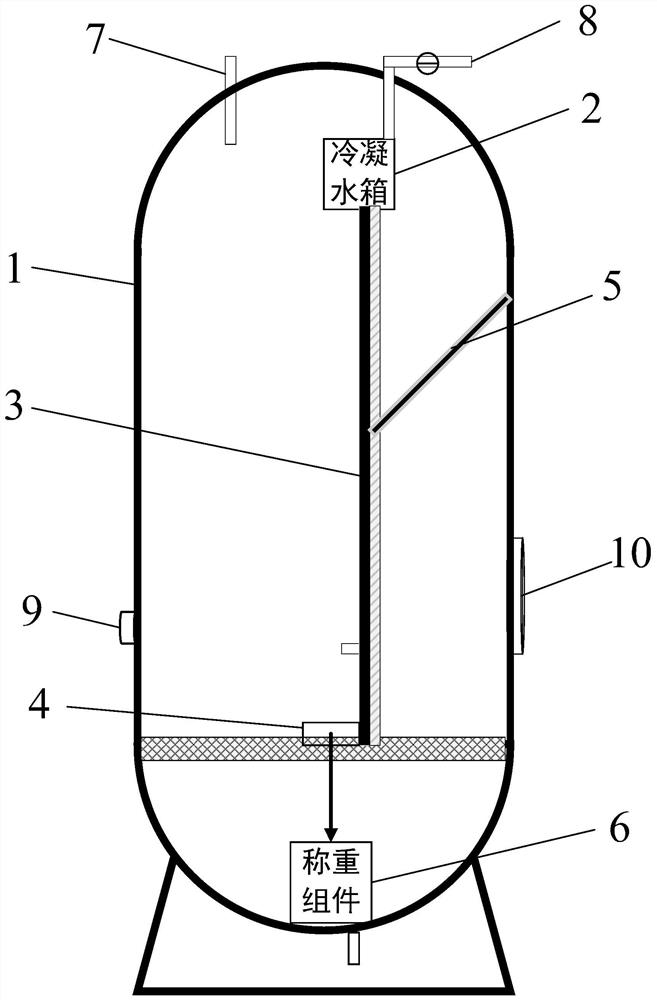

[0024] Such as figure 1 , figure 2 As shown, a test device for testing the recovery efficiency of condensate on the inner wall of the containment of a nuclear power plant, the device includes a tank body 1 for simulating the containment of a nuclear power plant, a condensate return assembly for simulating condensate return and collecting condensate water, and a condensate return assembly for collecting condensate The weighing component 6 for weighing the condensed water, the condensate return component and the weighing component 6 are all arranged inside the tank body 1, and the weighing component 6 is arranged at the condensate collecting end of the condensate return component. The weighing component 6 weighs the condensate recovered by the condensate return component, and calculates the condensate recovery efficiency by comparing with the inlet flow rate of the condensate return component.

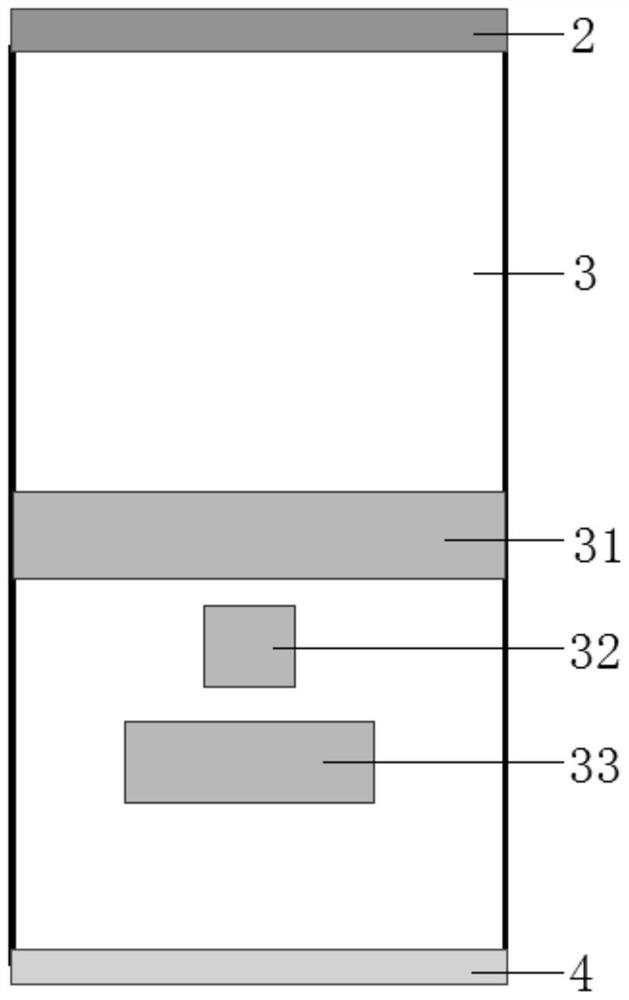

[0025] The condensate return assembly includes a condensate water tank 2, a test m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com