TGA-FTIR-based refined evaluation method for aging state of silicone rubber material

A technology of aging state and silicone rubber, which is applied to the analysis of materials, thermal development of materials, and material analysis through optical means. It can solve the problems of relatively large errors in the aging evaluation methods of silicone rubber materials, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

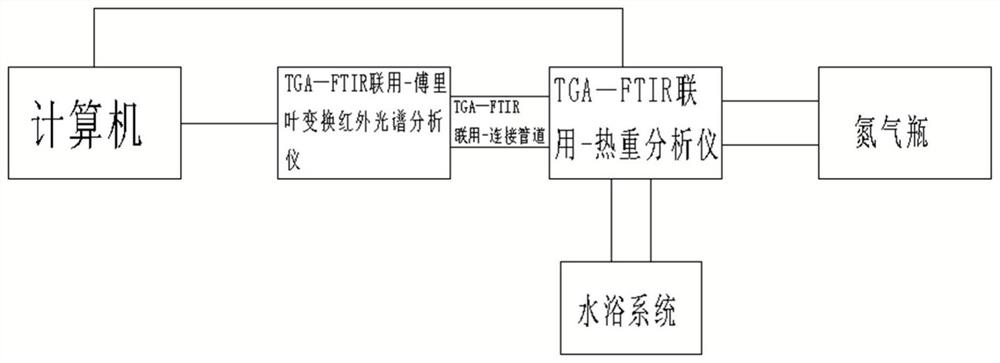

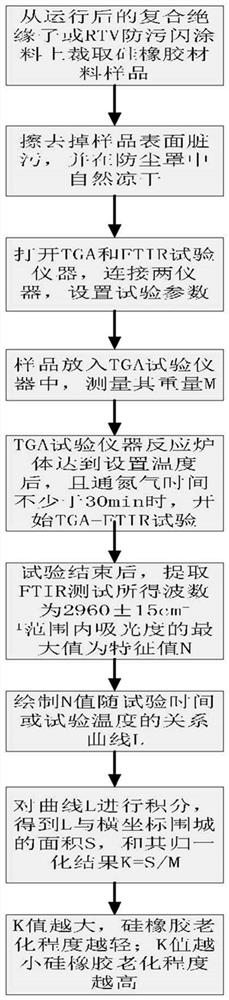

[0037] like Figure 1-Figure 5 As shown, the present invention comprises the following steps,

[0038] (1) Sample preparation, select the silicone rubber material after operation as the test sample; cut the sample from the silicone rubber material after operation, and keep the contact surface with the air during the sample operation process, the sample weight is 20mg±3mg, the sample The thickness does not exceed 1mm. Wipe off the dirt on the surface of the test sample with absolute ethanol, and then place it in a dust cover to dry naturally.

[0039] (2) Connect the gas measurement unit of the FTIR experimental instrument with the TGA test unit and set the test parameters;

[0040] (3) Carry out TGA-FTIR test to sample respectively;

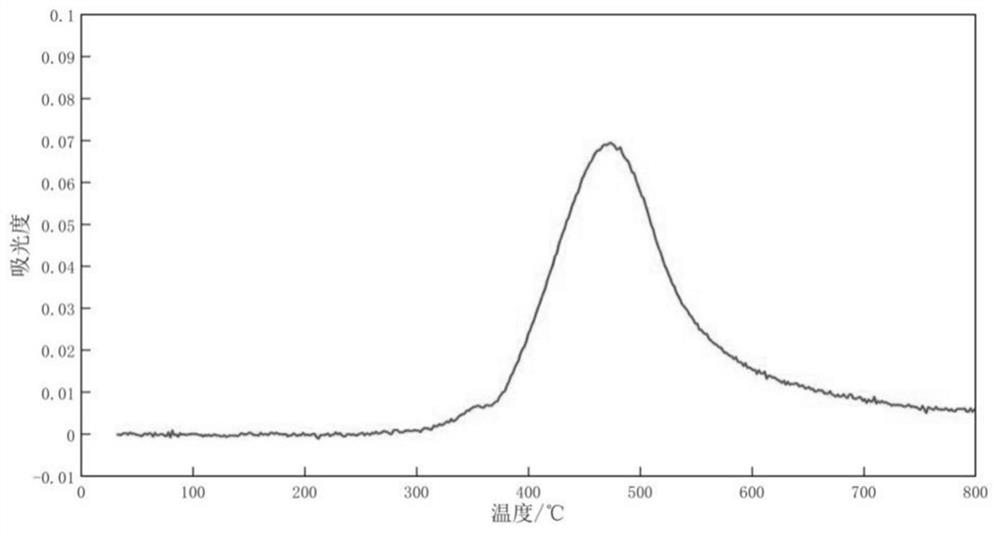

[0041] (4) draw the characteristic curve;

[0042] (5) Evaluation of aging degree.

[0043] The specific operation is as follows:

[0044] (1) Select 3 composite insulators after operation, and use a wallpaper knife to cut out silicone rubb...

Embodiment 2

[0062] It includes the following steps,

[0063] (1) Sample preparation, the silicone rubber material after operation is selected as the test sample; in step (1), the sample is cut from the silicone rubber material after operation, and the contact surface with the air should be kept intact during the sample operation process, and the sample weight It is 20mg ± 3mg, and the thickness of the sample does not exceed 1mm.

[0064] Wipe off the dirt on the surface of the test sample with absolute ethanol, and then place it in a dust cover to dry naturally.

[0065] (2) Connect the gas measurement unit of the FTIR experimental instrument with the TGA test unit and set the test parameters;

[0066] (3) Carry out TGA-FTIR test to sample respectively;

[0067] (4) draw the characteristic curve;

[0068] (5) Evaluation of aging degree.

[0069] The specific operation is as follows:

[0070] (1) Select 3 composite insulators after operation, and use a wallpaper knife to cut out silic...

Embodiment 3

[0086] It includes the following steps,

[0087] (1) Sample preparation, select the silicone rubber material after operation as the test sample; in step (1), the sample weight is 20mg±3mg, the contact surface between the sample and the air should be kept intact during the sample operation, and the sample thickness should not exceed 1mm. Wipe off the dirt on the surface of the test sample with absolute ethanol, and then place it in a dust cover to dry naturally.

[0088] (2) Connect the gas measurement unit of the FTIR experimental instrument with the TGA test unit and set the test parameters;

[0089] (3) Carry out TGA-FTIR test to sample respectively;

[0090] (4) draw the characteristic curve;

[0091] (5) Evaluation of aging degree.

[0092] The specific operation is as follows:

[0093] (1) Select 3 composite insulators after operation, and use a wallpaper knife to cut out silicone rubber samples of similar shape and size on the upper surface of the shed at the high vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com